Synthesis method of Ln0.3Sr0.7Fe0.7Cr0.3O<3-delta> ion electronic mixed conductor material

A synthesis method and technology of mixed conductors, which are applied in chemical instruments and methods, circuits, electrical components, etc., can solve the problems of not fully meeting the coordination requirements of rare earth metal ions and cannot be highly ordered combination, and achieve fine particles and make up for coordination. Insufficient positional ability, effect of strong coordination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] By product Pr 0.3 Sr 0.7 Fe 0.7 Cr 0.3 o 3-δ The stoichiometric ratio of the corresponding Pr, Sr, Fe, Cr nitrates were respectively weighed, dissolved in deionized water in turn, and then added diethylenetriaminepentaacetic acid and triethylenetetraminehexaacetic acid, diethylenetriaminepentaacetic acid, The molar ratio of triethylenetetraminehexaacetic acid to the total amount of various metal ions is 0.7:0.6:1.0. An appropriate amount of ammonia water was added dropwise to the mixed solution to adjust its pH value to 7-8, and the mixed solution was heated to 90° C. and stirred for 4 hours in a water bath to form a clear and transparent precursor solution. After the precursor solution is heated to 100°C and aged for 24 hours, a solid precursor is obtained. Finally, the solid precursor was ground and heat-treated at 1000°C for 2 hours, and the obtained black fine powder was the synthesis product.

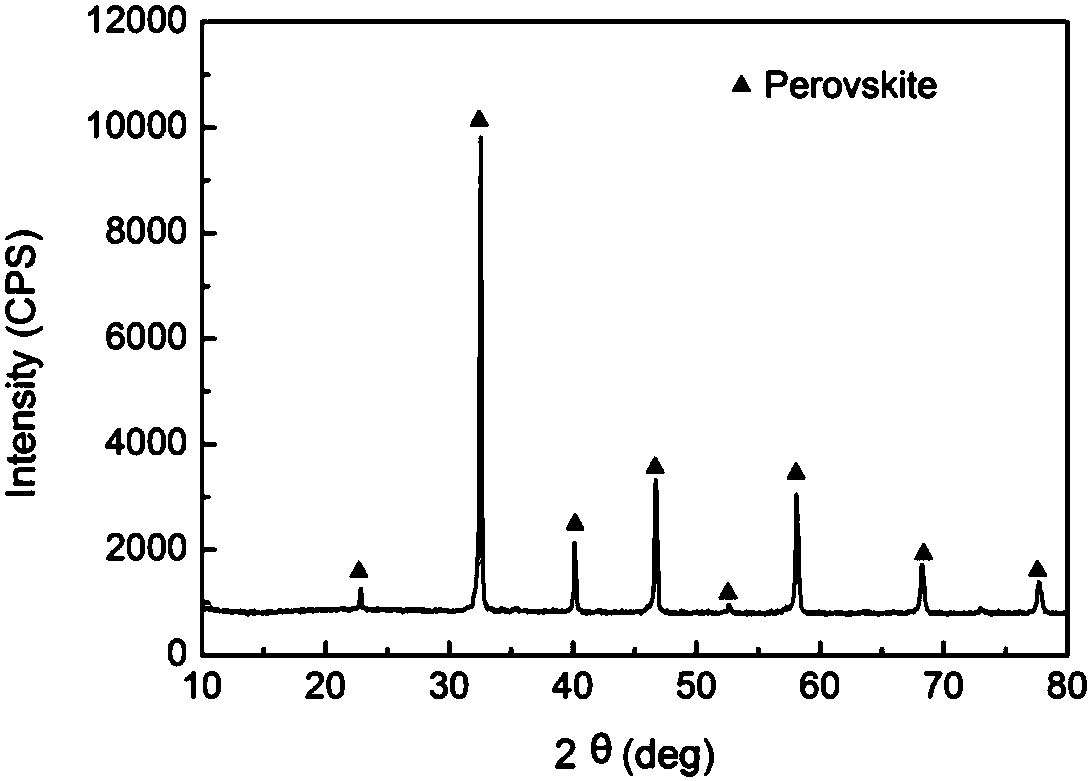

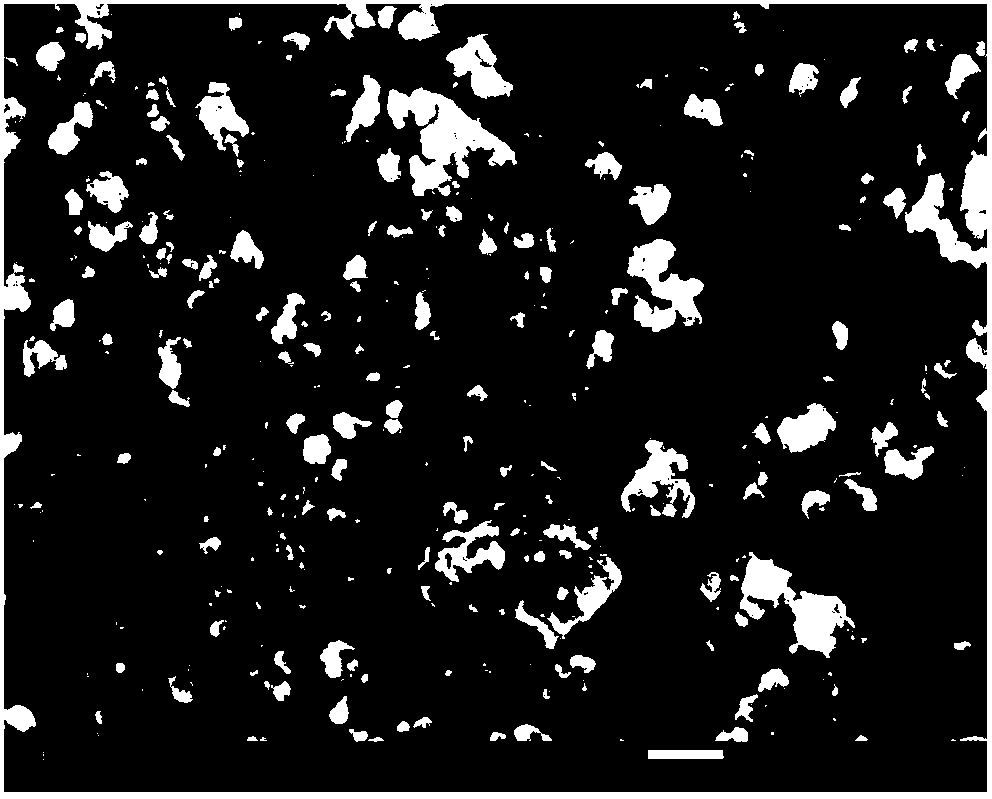

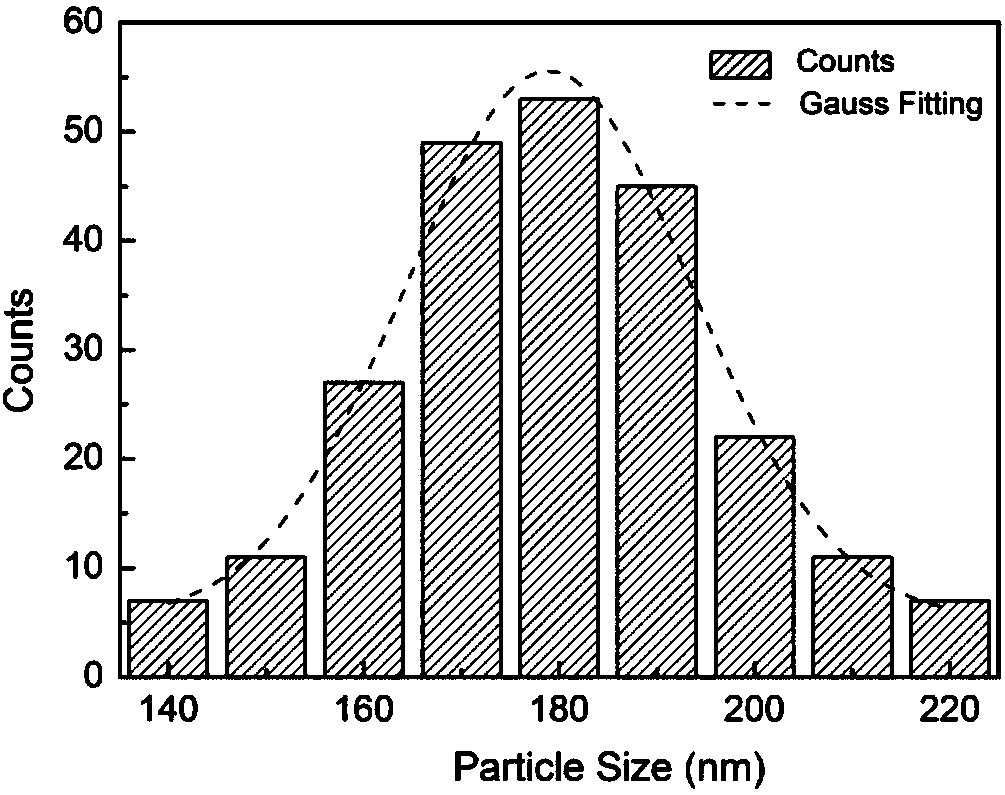

[0024] The synthesized powder product was analyzed by XRD, SEM an...

Embodiment 2

[0026] By product Nd 0.3 Sr 0.7 Fe 0.7 Cr 0.3 o 3-δ Weigh the corresponding nitrates of Nd, Sr, Fe, Cr respectively, dissolve them in deionized water in sequence, then add diethylenetriaminepentaacetic acid and triethylenetetraminehexaacetic acid, diethylenetriaminepentaacetic acid, The molar ratio of triethylenetetraminehexaacetic acid to the total amount of various metal ions is 0.7:0.5:1.0. An appropriate amount of ammonia water was added dropwise to the mixed solution to adjust its pH value to 7-8, and the mixed solution was heated to 80° C. and stirred for 5 hours in a water bath to form a clear and transparent precursor solution. After the precursor solution is heated to 100°C and aged for 20 hours, a solid precursor is obtained. Finally, the solid precursor was ground and heat-treated at 1000°C for 3 hours, and the obtained black fine powder was the synthesis product.

[0027] After testing, the Nd prepared in this embodiment 0.3 Sr 0.7 Fe 0.7 Cr 0.3 o 3-δ Th...

Embodiment 3

[0029] By product Sm 0.3 Sr 0.7 Fe 0.7 Cr 0.3 o 3-δ Weigh the corresponding nitrates of Sm, Sr, Fe, Cr respectively, dissolve them in deionized water in turn, then add diethylenetriaminepentaacetic acid and triethylenetetraminehexaacetic acid, diethylenetriaminepentaacetic acid, The molar ratio of triethylenetetraminehexaacetic acid to the total amount of various metal ions is 0.8:0.6:1.0. An appropriate amount of ammonia water was added dropwise to the mixed solution to adjust its pH value to 7-8, and the mixed solution was heated to 85° C. and stirred for 6 hours in a water bath to form a clear and transparent precursor solution. After the precursor solution is heated to 100°C and aged for 24 hours, a solid precursor is obtained. Finally, the solid precursor was ground and heat-treated at 1030°C for 2 hours, and the obtained black fine powder was the synthesis product.

[0030] After testing, the Sm prepared in this example 0.3 Sr 0.7 Fe 0.7 Cr 0.3 o 3-δ The powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com