Multiwall carbon nanotube cement-based composite material and preparation method thereof

A technology of multi-wall carbon nanotubes and composite materials, which is applied in the field of multi-wall carbon nanotube cement-based composite materials and its preparation, can solve problems such as multi-wall carbon nanotube agglomeration, and achieves simple and easy operation, small average pore size, cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

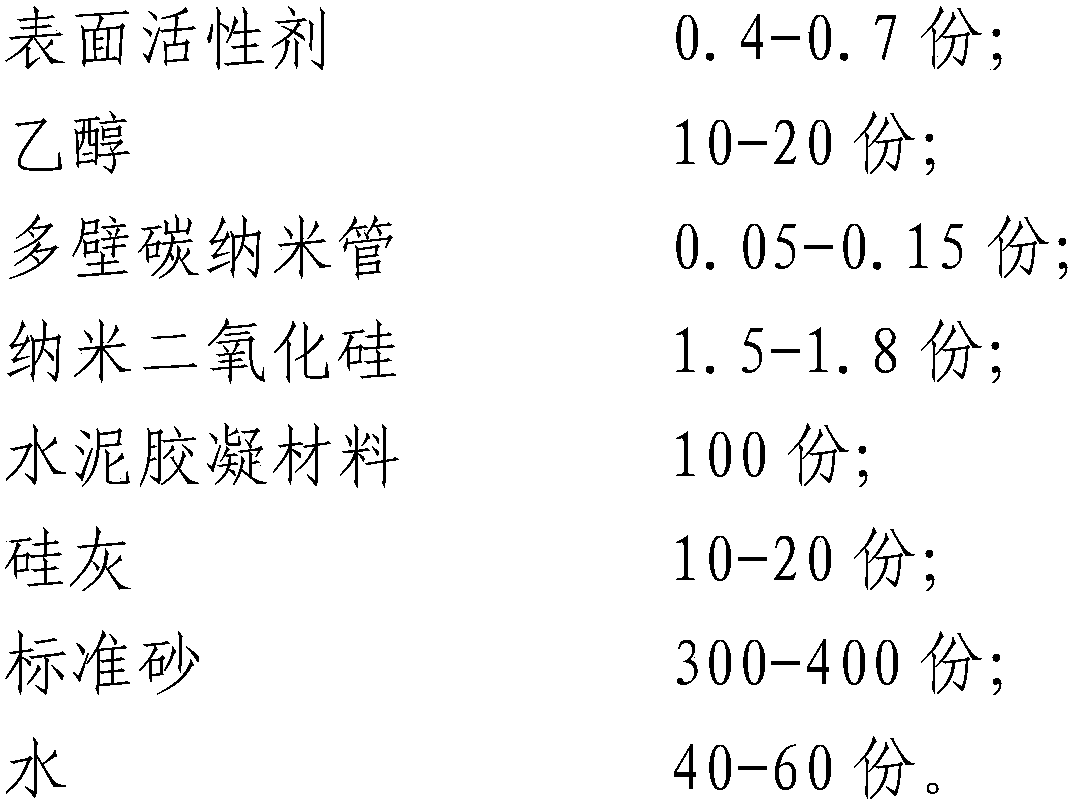

[0030] The preparation method specifically comprises the following steps:

[0031] Step 1, add the surfactant into ethanol and stir until completely dissolved; wherein, the surfactant is alkylphenol polyoxyethyl ether, sodium lauryl sulfate, sodium dodecylbenzenesulfonate, dodecyl One or more of sodium sulfonate, polyvinylpyrrolidone, and gum arabic.

[0032] Step 2, add multi-walled carbon nanotubes, nano-silica and glass beads, and perform mechanical stirring, grinding and dispersion for 1-1.5 hours;

[0033] Step 3, after filtering, place in an ultrasonic dispersion device for 0.5-1 hour ultrasonic dispersion to obtain a multi-walled carbon nanotube dispersion;

[0034] Step 4, after stirring the cementitious material, silica fume, and standard sand with water, add the dispersion liquid obtained in step 3, and stir evenly;

[0035] Step 5, put the multi-walled carbon nanotube cement-based slurry uniformly stirred in step 4 into a drying oven to keep at 50°C-60°C, and dry ...

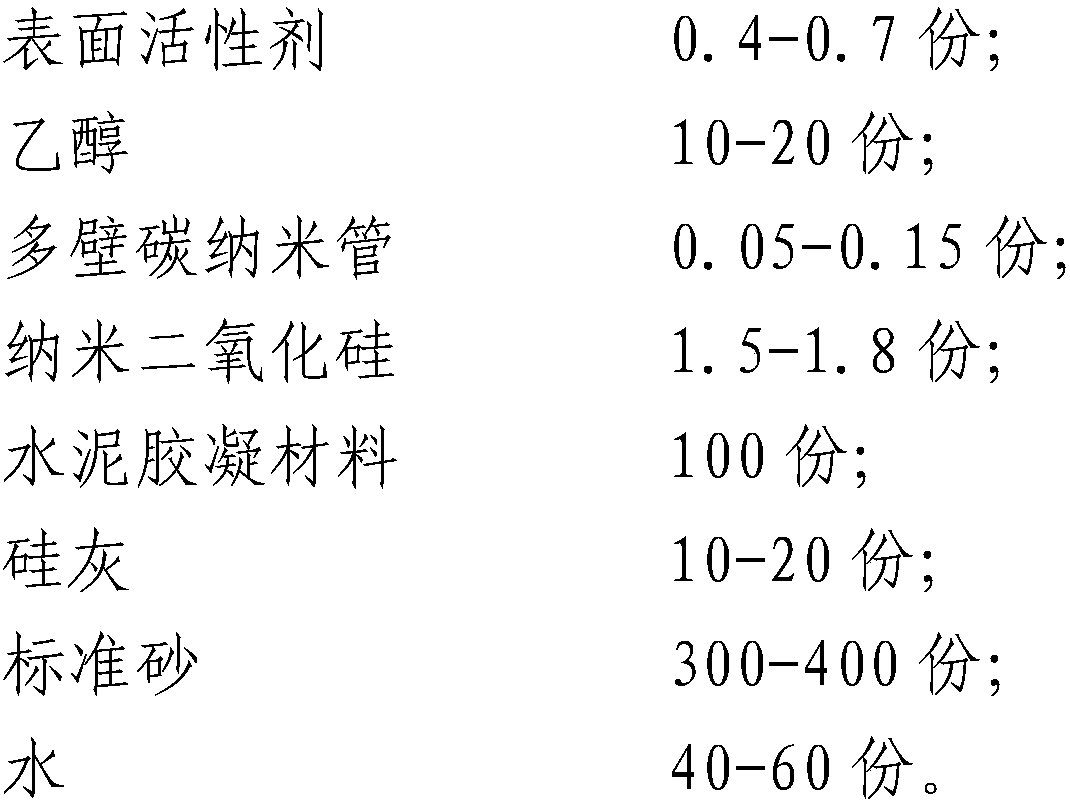

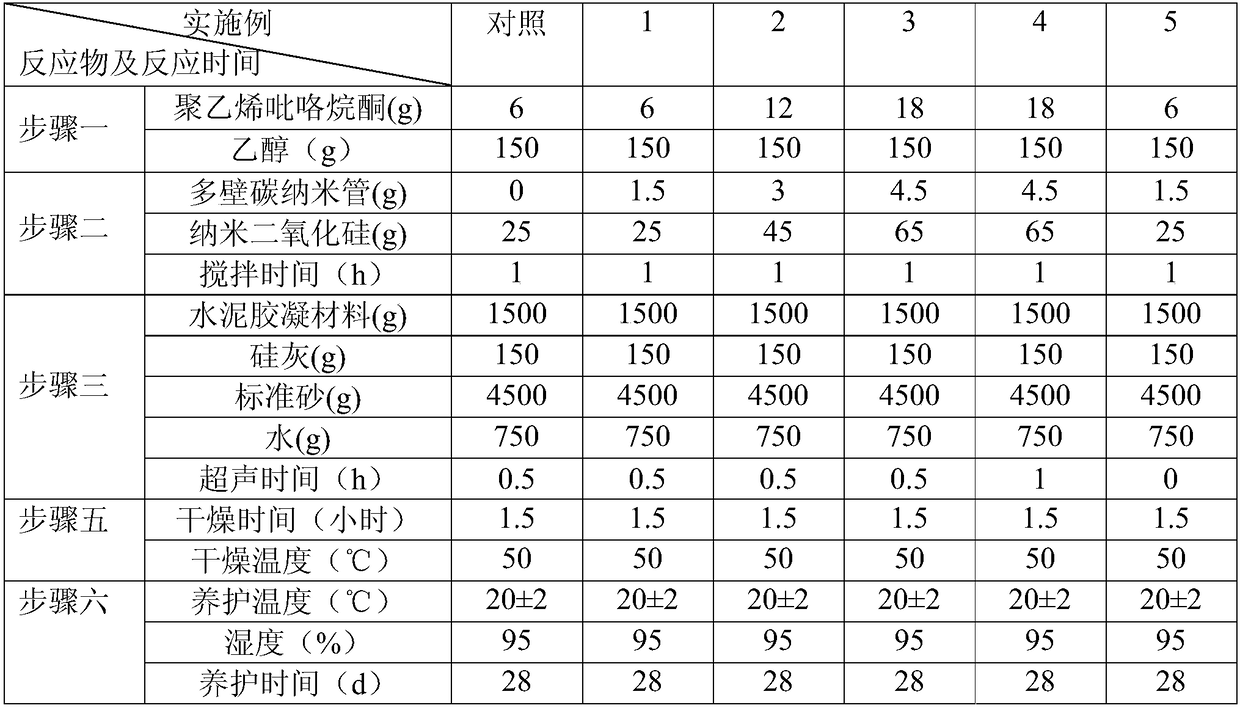

Embodiment 1-5

[0041] Embodiment 1-5 concrete performance test sees the following table:

[0042] Table 2 Examples 1-5 Composite mechanical properties

[0043]

[0044] The following conclusions can be drawn from the results in Table 2:

[0045] (1) It can be seen from the control group that the compressive strength of the concrete test block prepared without adding carbon nanotubes is about 48MPa. Examples 1-3 all add a certain amount of multi-walled carbon nanotubes and after ultrasonic treatment, the mechanical properties of the cement-based composite material are significantly improved, and the compressive strength is increased by 11.6%-20.99%.

[0046] (2) In Example 3 and Example 4, although the addition ratio of carbon nanotubes is the same as 0.3%, the mechanical properties of the cement-based composite material in Example 4 do not increase but decrease, because the addition of carbon nanotubes is too high , not well dispersed, agglomeration occurred in the cement-based material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com