Semiconductor laser based on an indium phosphide-base coupled ridge array and preparation method thereof

An indium phosphide-based laser technology, which is applied to the structure of semiconductor lasers, lasers, and optical waveguide semiconductors, can solve the problems of beam quality degradation and enlarging lasers, and achieve simple processing, high quality, and short-circuit prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

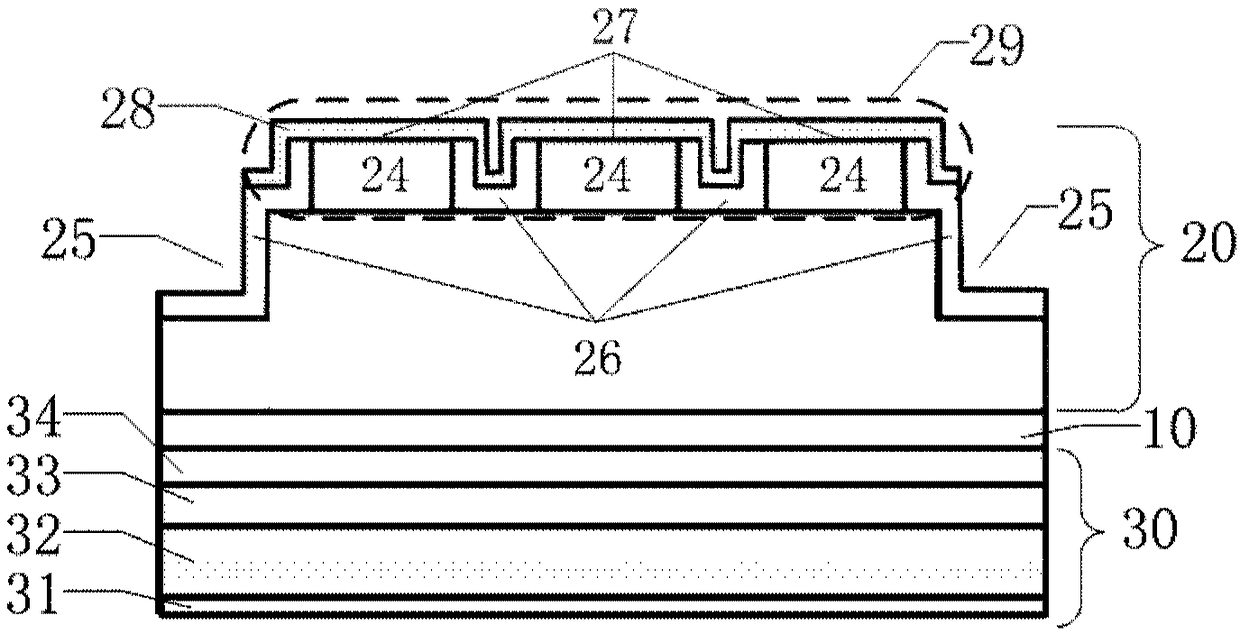

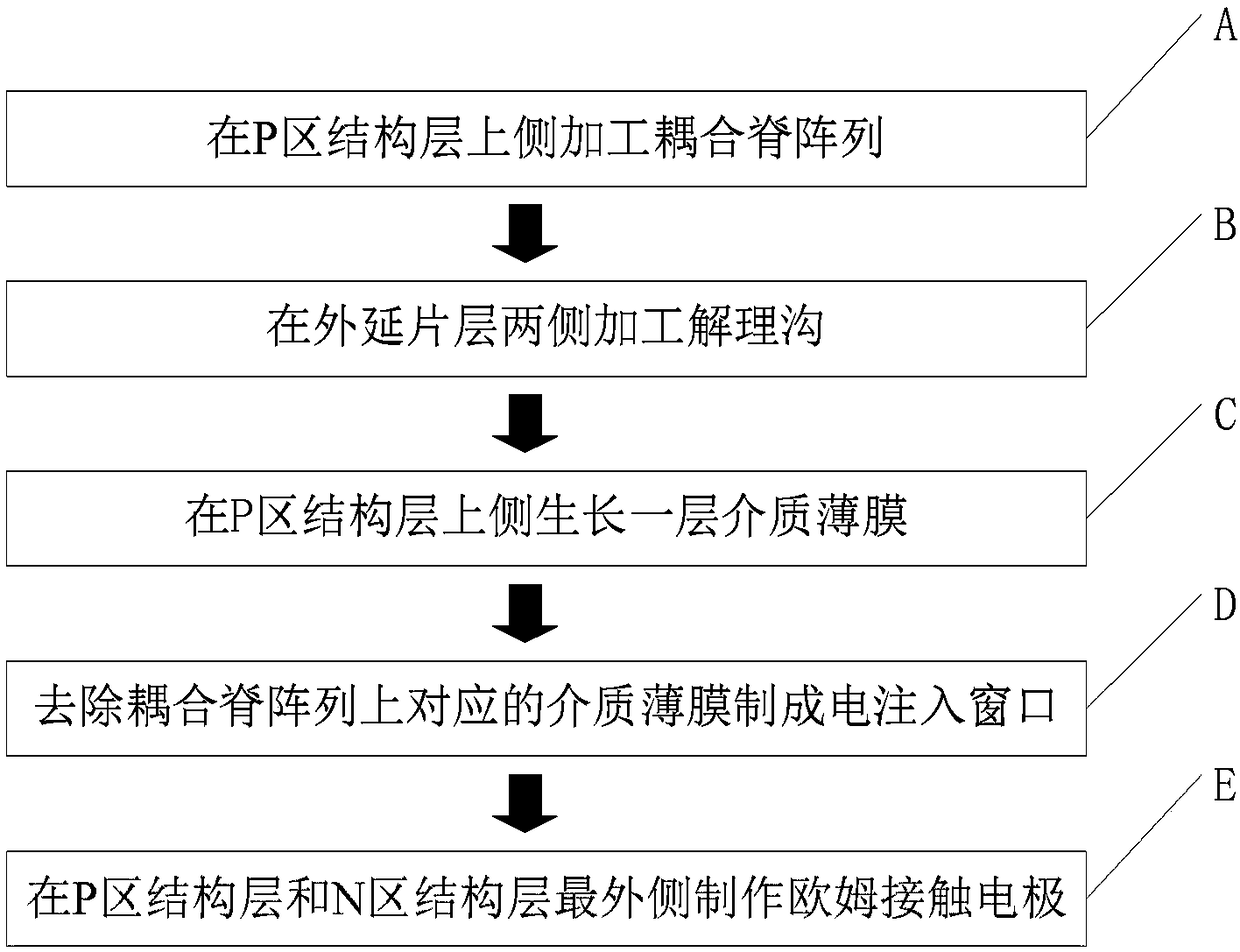

[0056] The present disclosure also provides a method for manufacturing a semiconductor laser based on an indium phosphide-based coupled ridge array. The semiconductor laser is processed on an indium-phosphide-based epitaxial wafer, figure 2 It is a schematic flow chart of the preparation method, such as figure 2 Shown, described preparation method comprises the following steps:

[0057] Step A: Process the coupling ridge array 29 on the P-region structural layer 20, including:

[0058] Sub-step A1: InP-based epitaxial wafer (such as Figure 5 As shown), the upper side of the P region structure layer is made with a photoresist with a coupling ridge array pattern, and the thickness of the photoresist is 0.5 μm-5 μm, such as Image 6 shown; and

[0059] Sub-step A2: using the photoresist completed in sub-step A1 as a mask, etch away the part of the epitaxial wafer that is not protected by the photoresist, and the etching depth is 200nm-3μm, such as Figure 7 shown.

[0060...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Corrosion depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com