Blue sun-proof offset printing ink and preparation method thereof

A technology of offset printing ink and light fastness, which is applied in ink, household utensils, applications, etc., can solve the problems of poor light fastness, limited printing speed, poor printing effect of blue offset printing ink, etc., and facilitates large-scale promotion and application , Easy preparation and operation, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

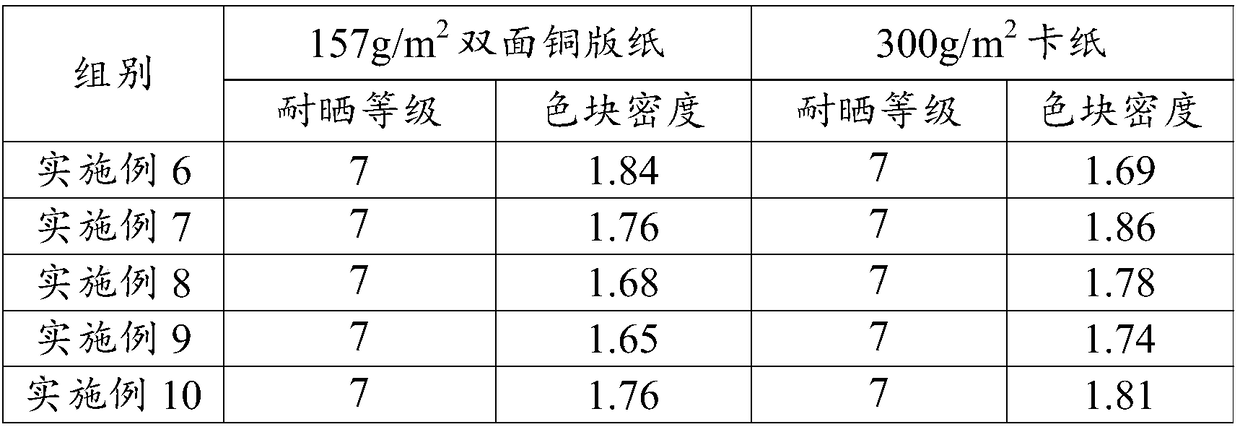

Examples

preparation example Construction

[0045] According to one aspect of the present invention, a kind of preparation method of blue sunfast offset printing ink, described preparation method comprises the following steps:

[0046] First, fully stir the offset printing binder, lubricant, emulsifier and drier until they are all dissolved, and prepare a semi-finished product A; then, add the dry phthalocyanine blue powder, permanent violet and fillers to the semi-finished product A, and stir until uniformly dispersed , to make a semi-finished product B; finally, fully grind the semi-finished product B to reach the corresponding fineness of the ink, and obtain a blue light-fast offset printing ink.

[0047] The preparation method of the above-mentioned blue light-resistant offset printing ink of the present invention has the advantages of simple preparation and operation, low processing cost, no need of special processing equipment in the processing process, and convenient large-scale popularization and application.

Embodiment 1

[0050] A blue light-resistant offset printing ink, in parts by weight, said blue light-resistant offset printing ink is mainly made of the following raw materials: 50 parts of offset printing binder, 10 parts of pigment, 2 parts of wax paste, 2 parts of lubricant, 5 parts of filler, 0.1 part of emulsifier and 0.5 part of drier;

[0051] The pigment is mainly composed of phthalocyanine blue dry powder and permanent violet, and the mass ratio of the phthalocyanine blue dry powder to permanent violet is 2:1;

[0052] The offset printing binder comprises the following components by weight percentage: 50% rosin modified phenolic resin, 28% alkyd resin, 15% vegetable oil, 5% mineral oil, 1% organic aluminum gel forming agent and antioxidant 1%;

[0053] Described lubricant is industrial white oil;

[0054] The filler is nanoscale active calcium carbonate SPO-100;

[0055] The drier is composed of manganese isooctanoate and cobalt isooctanoate, and the compounding mass ratio of ma...

Embodiment 2

[0057] A blue sunfast offset printing ink, in parts by weight, said blue sunfast offset printing ink is mainly made of the following raw materials: 70 parts of offset printing binder, 20 parts of pigment, 8 parts of wax paste, 10 parts of lubricant, 15 parts of filler, 1 part of emulsifier and 2 parts of drier;

[0058] The pigment is mainly composed of phthalocyanine blue dry powder and permanent violet, and the mass ratio of the phthalocyanine blue dry powder to permanent violet is 3:1;

[0059] The offset printing binder comprises the following components by weight percentage: 40% rosin modified phenolic resin, 30% alkyd resin, 20% vegetable oil, 6% mineral oil, 3% organic aluminum gel forming agent and antioxidant 1%;

[0060] Described lubricant is industrial white oil;

[0061] The filler is nanoscale active calcium carbonate SPO-100;

[0062] The drier is composed of manganese isooctanoate and cobalt isooctanoate, and the mass ratio of manganese isooctanoate and coba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com