Biomass character paper preparation method and use method thereof

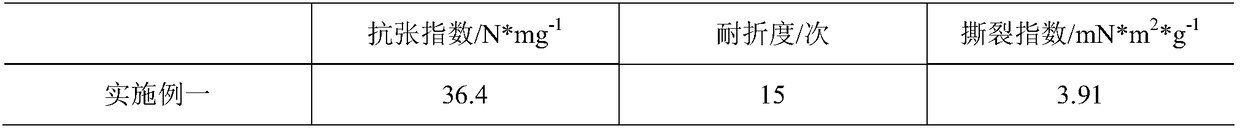

A biomass and characteristic technology, applied in the field of agricultural cultivation, can solve problems such as damage to the digestive system, affecting the appearance of the city and crop production, and achieve the effects of eliminating white pollution, returning straw to the field, and reducing the use of plastics.

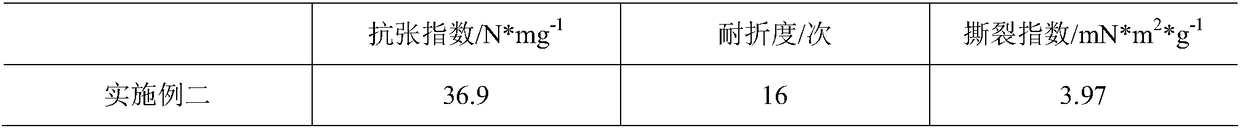

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] A method for preparing biomass characteristic paper, comprising the steps of: using plant stalks (plant stalks are corn stalks, rice stalks, cotton stalks, hemp stalks, and wheat stalks) to add papermaking auxiliary agents to make paper;

[0032] Step 1. Weighing a certain weight of plant straw, starch, agricultural resin, nutrients, trace elements, and clean water according to the parts by weight;

[0033] Step 2, cutting the weighed plant stalks into 10cm segments;

[0034] Step 3, add a certain amount of clean water to the cut straw, and cook at high temperature, and the primary slurry obtained after cooking is ready for use;

[0035] Step 4. Add weighed starch, agricultural resin, and papermaking additives to the primary slurry prepared in step 2, mix evenly, place in a beater for beating, and sieve the product obtained after beating to obtain a secondary slurry ;

[0036] Step 5, adding weighed nutrients and trace elements to the secondary slurry prepared in step...

specific Embodiment approach 2

[0049] The method for using biomass characteristic paper according to specific embodiment 1 includes the following steps: using plant stalks (plant stalks are corn stalks, rice stalks, cotton stalks, hemp stalks, and wheat stalks) to add papermaking auxiliary agents to make paper;

[0050] Step a, reeling and cutting the biomass characteristic paper into different shapes to make seedling raising barrels, seedling raising trays, and mulch paper;

[0051] Step b. Fill the seedling buckets, seedling trays, and plastic film paper prepared in step a with original soil, water thoroughly, and then sow or transplant rice seedlings.

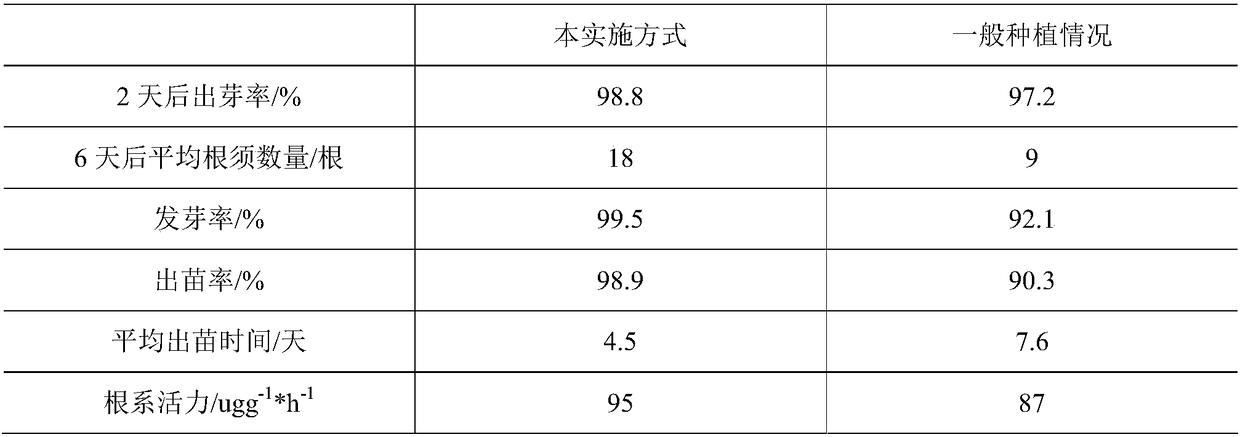

[0052] The use method of the biomass characteristic paper described in this embodiment is made into a seedling tray for cultivating watermelon seedlings. The cultivation situation is compared with the general planting method, and the situation comparison is shown in Table 2:

[0053] Table 2 Comparison table of watermelon cultivation

[0054]

specific Embodiment approach 3

[0055] A method for preparing biomass characteristic paper, comprising the steps of: using plant stalks (plant stalks are corn stalks, rice stalks, cotton stalks, hemp stalks, and wheat stalks) to add papermaking auxiliary agents to make paper;

[0056] Step 1. Weigh a certain weight of plant straw, starch, agricultural resin, papermaking additives, nutrients, trace elements, and deionized water according to the parts by weight;

[0057] Step 2, cutting the weighed plant stalks into 12cm segments;

[0058] Step 3, add a certain amount of clean water to the cut straw, and cook at high temperature, and the primary slurry obtained after cooking is ready for use;

[0059] Step 4. Add weighed starch, agricultural resin, and papermaking additives to the primary slurry prepared in step 2, mix evenly, place in a beater for beating, and sieve the product obtained after beating to obtain a secondary slurry ;

[0060] Step 5, adding weighed nutrients and trace elements to the secondary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com