A surface-enhanced Raman substrate and its preparation method

A substrate and substrate technology, applied in the field of surface-enhanced Raman substrate and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

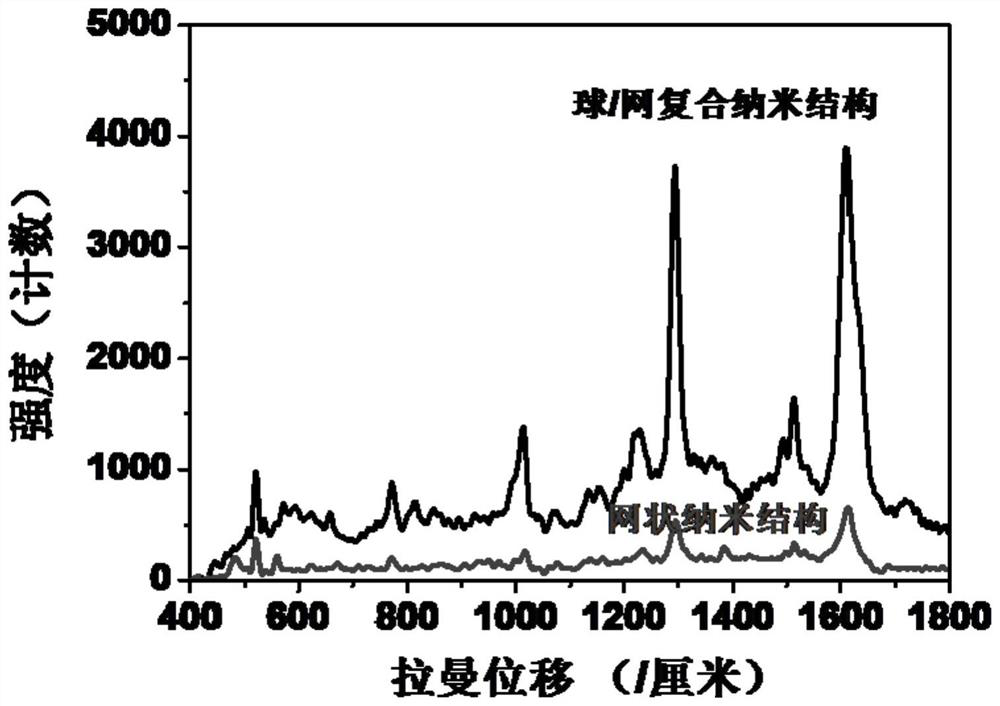

[0087] This embodiment provides a method for preparing a surface-enhanced Raman substrate, the specific method of which is:

[0088] (1) Clean the silicon (100) substrate, mix the negative electron beam resist HSQ and the positive electron beam resist PMMA 950k according to the volume ratio of 1:1, and ultrasonically disperse the mixed resist solution for 30 minutes. The e-beam resist was spin-coated to a thickness of 250 nm on a silicon substrate to obtain a coated substrate.

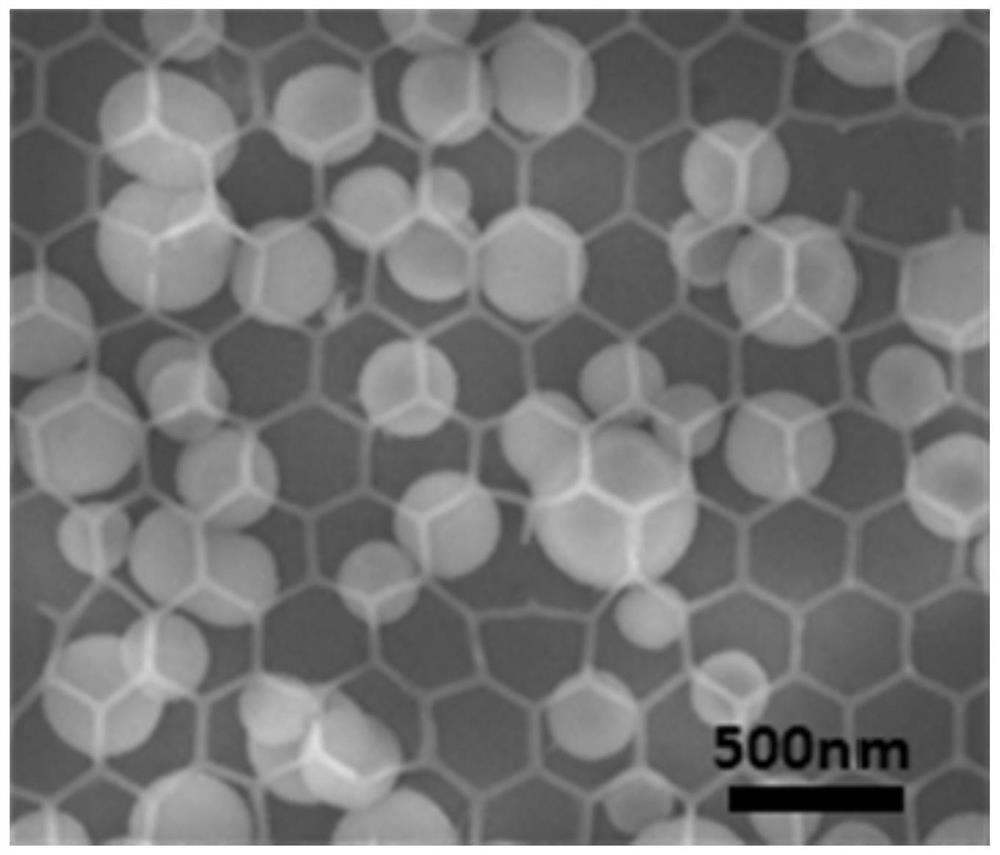

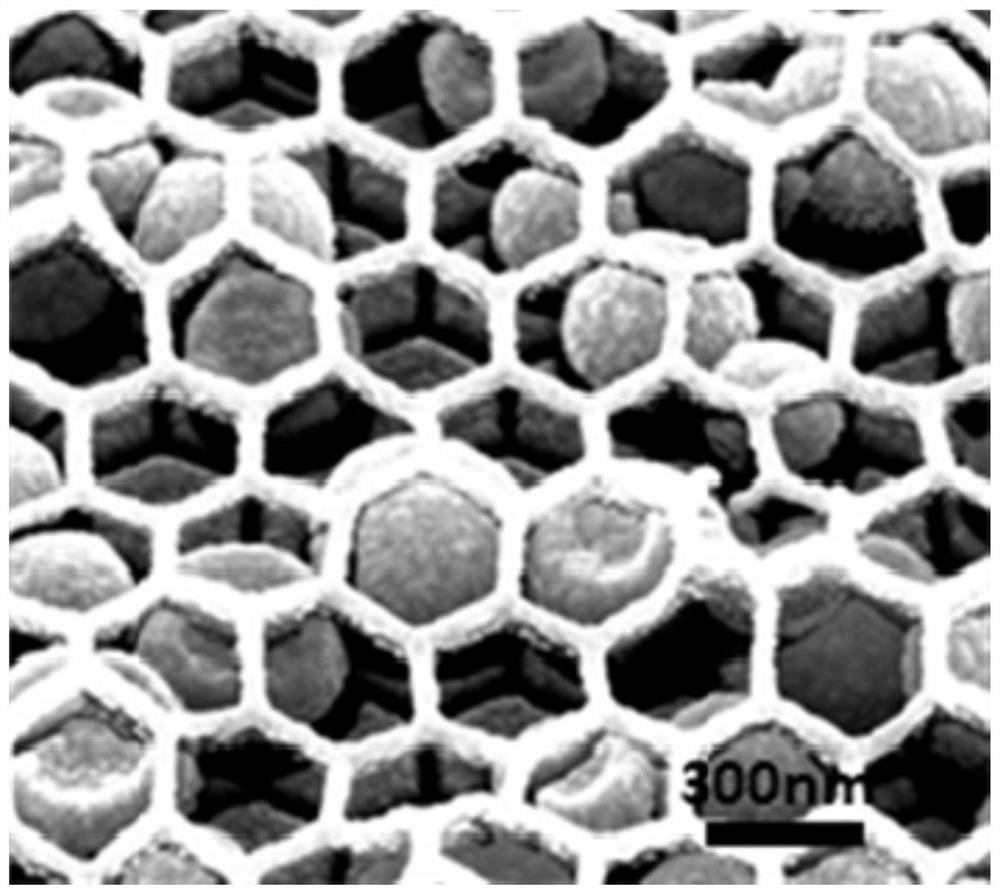

[0089] (2) On the coated substrate described in step (1), use an electron beam with a beam spot diameter of 6 nm to expose the electron beam resist, and adjust the exposure dose to 190000 μC / cm 2 The hexagonal nano-array pattern is directly written to obtain a substrate on which the nano-array pattern is written. The area of the nano-array pattern is 150 μm×150 μm, and the layout design line width of the nano-array pattern is 6 nm.

[0090] (3) Develop the substrate written in the nanoarray pattern ...

Embodiment 2

[0098] This embodiment provides a method for preparing a surface-enhanced Raman substrate, the specific method of which is:

[0099] (1) Clean the silicon (100) substrate, mix the negative electron beam resist HSQ and the positive electron beam resist ZEP520 according to the volume ratio of 3:2, ultrasonically disperse the mixed resist solution for 5 minutes, and The e-beam resist was spin-coated to a thickness of 400 nm on a silicon substrate to obtain a coated substrate.

[0100] (2) On the coated substrate described in step (1), use an electron beam with a beam spot diameter of 4 nm to expose the electron beam resist, and adjust the exposure dose to 120000 μC / cm 2 The hexagonal nano-array pattern is directly written to obtain a substrate on which the nano-array pattern is written. The area of the nano-array pattern is 250 μm×250 μm, and the layout design line width of the nano-array pattern is 4 nm.

[0101] (3) Develop the substrate written in the nanoarray pattern desc...

Embodiment 3

[0107] This embodiment provides a method for preparing a surface-enhanced Raman substrate, the specific method of which is:

[0108] (1) Clean the silicon (100) substrate, mix the negative electron beam resist HSQ and the positive electron beam resist PMMA 950k according to the volume ratio of 1:3, and ultrasonically disperse the mixed resist solution for 2 minutes, The e-beam resist was spin-coated to a thickness of 4800 nm on a silicon substrate to obtain a coated substrate.

[0109] (2) On the coated substrate described in step (1), use an electron beam with a beam spot diameter of 1 nm to expose the electron beam resist, and adjust the exposure dose to 200000 μC / cm 2 The triangular nano-array pattern is directly written to obtain a base on which the nano-array pattern is written. The area of the nano-array pattern is 10 μm×10 μm, and the layout design line width of the nano-array pattern is 1 nm.

[0110] (3) Develop the substrate written in the nanoarray pattern descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com