Method for preparing boron-nitrogen-carbon ternary material from carbon nitride

A ternary material and carbon nitride technology, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of requiring special equipment, difficulty in mass production, low yield, etc., to achieve high activity and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is used to illustrate the steps of the preparation method of the boron-nitrogen-carbon ternary material of the present invention as follows:

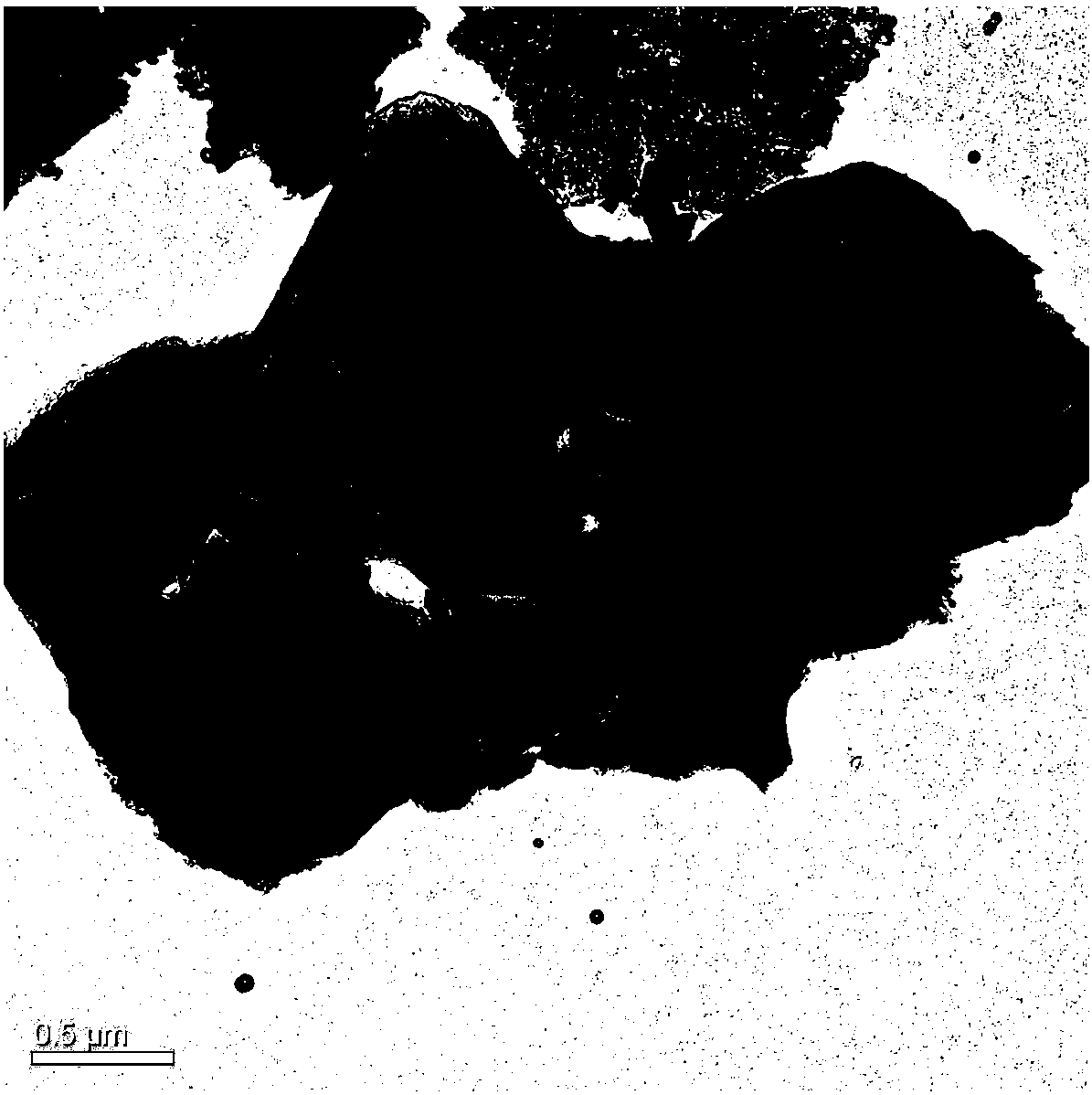

[0039] The melamine was placed in a crucible, the crucible was wrapped with tin foil, and placed in a muffle furnace at a heating rate of 5°C / min, and the temperature was raised to 600°C for 2 hours to prepare carbon nitride. Take 2g of carbon nitride and 2g of sodium borohydride and place them in a mortar and grind for 30 minutes; place the mixture in a tube furnace, under the protection of argon / hydrogen (95 / 5) mixed gas, at a heating rate of 5°C / min, After heating to 1000°C and reacting for 2 hours, the temperature is naturally lowered. The obtained black powder is repeatedly washed with water, centrifuged, and dried to obtain a boron-nitrogen-carbon ternary material. The final obtained boron-nitrogen-carbon ternary material is 1.72 g (yield is as high as 43%), and the molar percentage content of each element is det...

Embodiment 2

[0041] This example is used to illustrate the steps of the method for etching and stripping the boron-nitrogen-carbon ternary material of the present invention as follows:

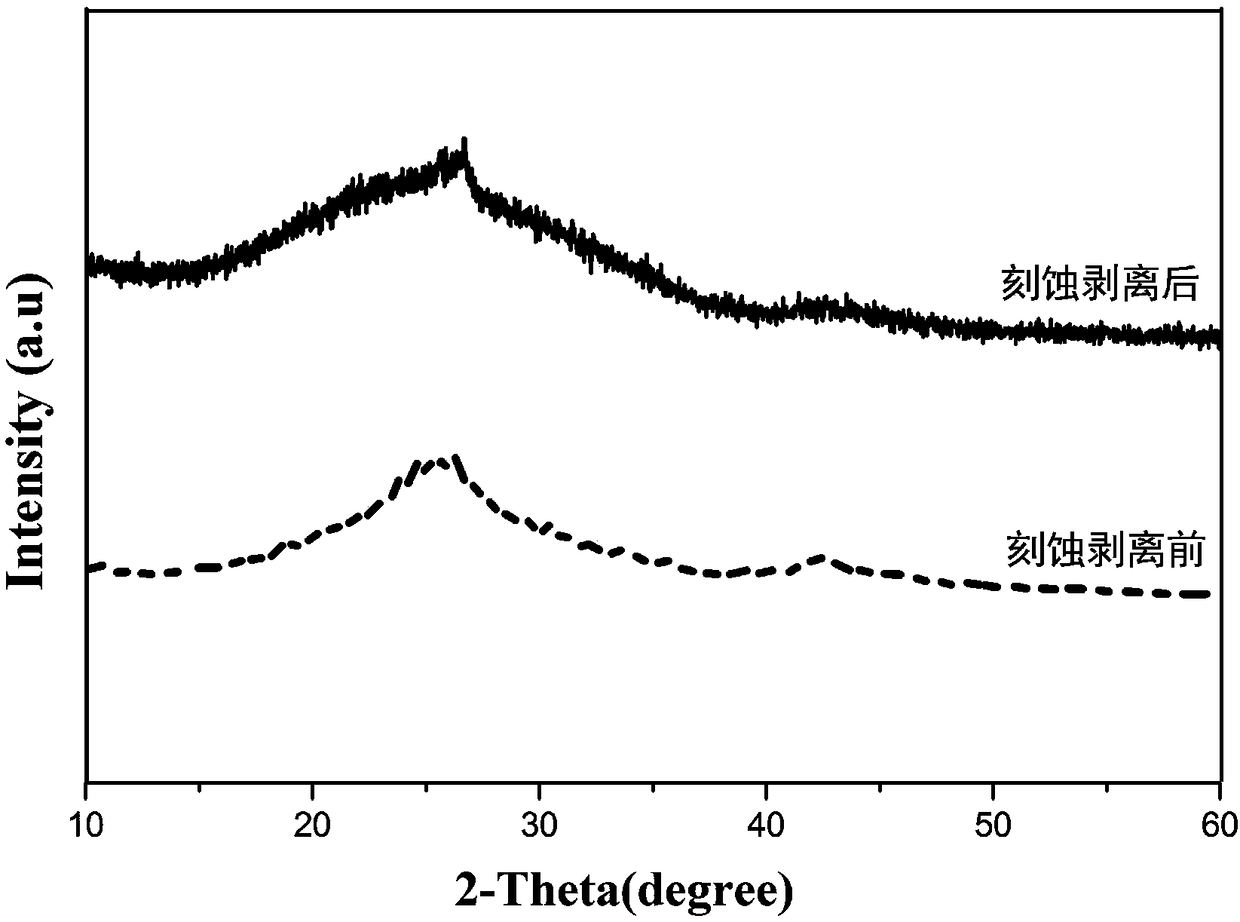

[0042] Dissolve 1g of the boron-nitrogen-carbon ternary material obtained in Example 1 and 1.5g of potassium hydroxide in 30ml of deionized water, sonicate or stir for 30min, raise the temperature to steam out the water in the mixture to obtain a mixed powder; Put the powder in a nickel crucible and put it in a tube furnace. Under the protection of argon / hydrogen (95 / 5) mixed gas, the temperature is raised to 800℃ at a heating rate of 5℃ / min for 2h. Cool down naturally. The obtained product is repeatedly washed with water and centrifuged until the pH value is close to neutral; after drying, the stripped boron-nitrogen-carbon ternary nanosheet material is obtained. The measured molar percentages of the elements are 33.69% boron, 34.75% nitrogen, 25.52% carbon, and 6.04% oxygen.

Embodiment 3

[0044] This example is used to illustrate the steps of the preparation method of the boron-nitrogen-carbon ternary material of the present invention as follows:

[0045] The melamine was placed in a crucible, the crucible was wrapped with tin foil, and placed in a muffle furnace. The temperature was raised to 600°C for 2h at a rate of 5°C / min to prepare carbon nitride. Take 2g of carbon nitride and 14g of tetrabutylammonium borohydride and grind for 30min in a mortar; place the mixture in a tube furnace under the protection of an argon / hydrogen (95 / 5) mixed gas at a heating rate of 5 ℃ / min. After heating to 1000℃ for 2h, the temperature will be cooled naturally. The obtained black powder is repeatedly washed with water, centrifuged, and dried to obtain a boron-nitrogen-carbon ternary material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com