High-char-forming, low-smoke, flame-retardant, anti-droplet copolyester based on aromatic ketone structure and its preparation method

A low-smoke flame-retardant and copolyester technology is applied in the field of new low-smoke flame-retardant and anti-melting droplet copolyester and its preparation field, which can solve the problems of polyester fusible droplets, toxic fumes, release, etc., and achieve barrier The effect of smoke release, reduction of heat release, and increase of flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

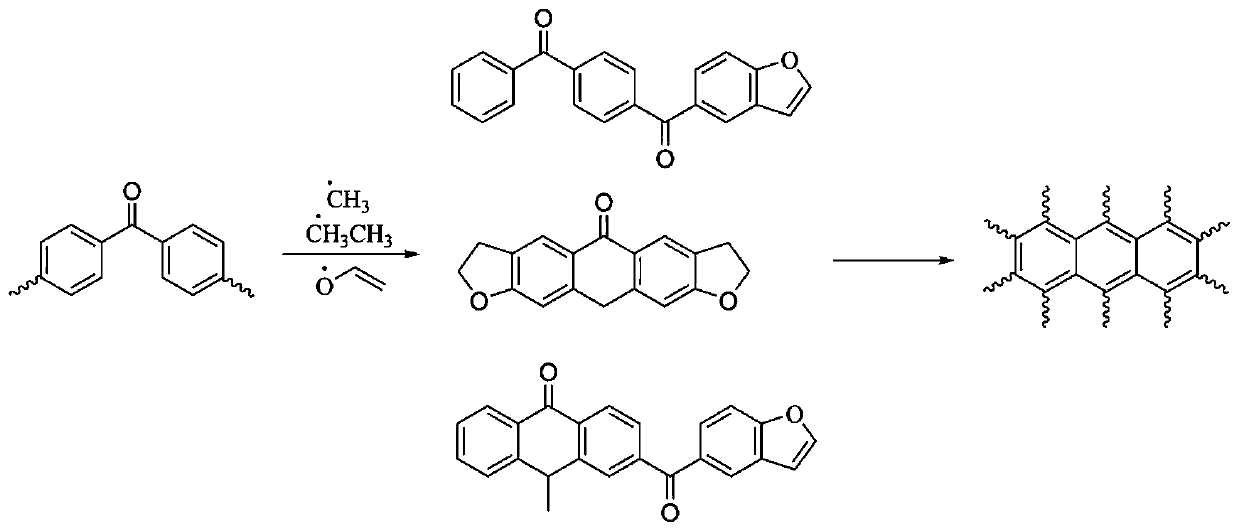

Method used

Image

Examples

Embodiment 1

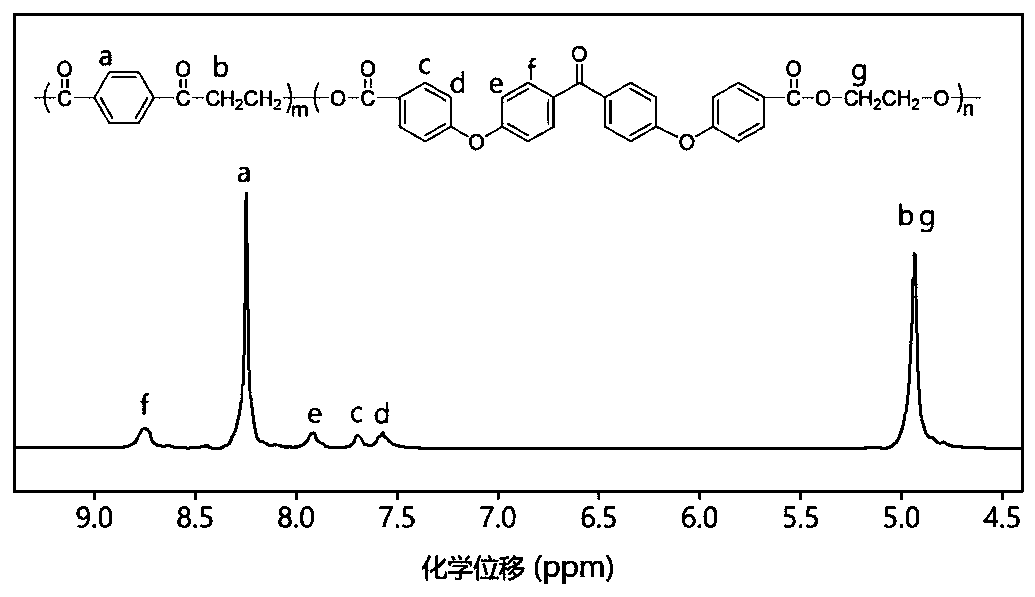

[0044] Add 960g of terephthalic acid, 360g of ethylene glycol, 1728g of 3,5-bis(2-hydroxyethoxy)benzophenone and 0.360g of ethylene glycol antimony into the reactor, and fill the reactor with nitrogen to remove the air in the reactor , pressurize to 0.1MPa, raise the temperature to 200°C within 2h to start the esterification reaction, control the pressure in the kettle to 0.3-0.4MPa, after maintaining for 1.5h, the pressure begins to decrease, and after 1.5h, the temperature gradually rises to 220°C, the pressure drops After reaching normal pressure, the esterification reaction is completed; after that, the polycondensation reaction is carried out at 230-240°C for 0.5h in low vacuum, and then the temperature is raised to 250°C for 2h in high vacuum (pressure <60Pa).

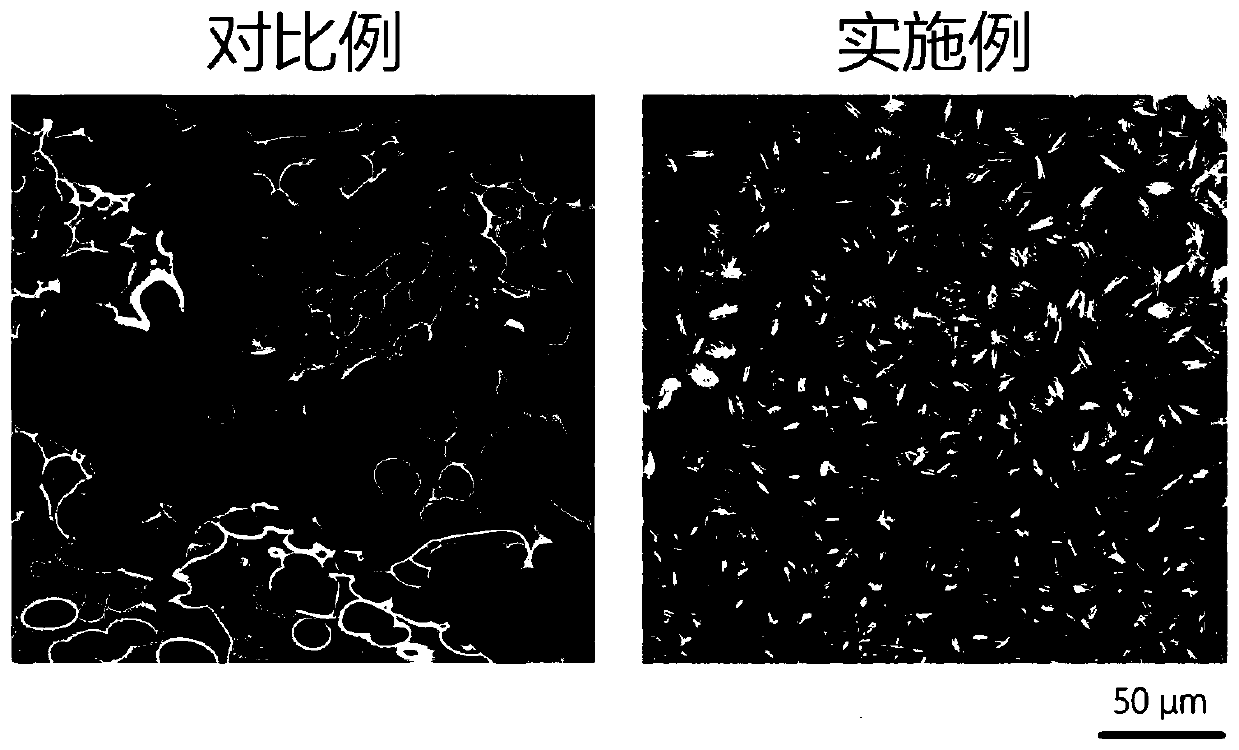

[0045] The intrinsic viscosity [η] of the copolyester is 0.77dL / g; the limiting oxygen index is 39.0; the vertical combustion level is V-0, and no droplet is produced from two ignition to extinguishment in vertica...

Embodiment 2

[0047] 960g of terephthalic acid, 360g of ethylene glycol, 175g of 3,4-bis(2-hydroxyethoxy)benzophenone and 0.360g of ethylene glycol antimony were added to the reaction kettle, according to the method given in Example 1 Steps and conditions After the esterification and polycondensation reactions are carried out, the material is discharged.

[0048] The intrinsic viscosity [η] of the copolyester is 0.61dL / g; the limiting oxygen index is 30.0; the vertical combustion level is V-1, and no droplet is produced from two ignition to extinguishment in vertical combustion; cone calorimetry test Medium peak heat release rate PHRR is 439kW / m 2 , the total smoke release TSR is 1429m 2 / m 2 .

Embodiment 3

[0050] 960g of terephthalic acid, 360g of ethylene glycol, 1550g of 3,4-diacetoxybenzophenone and 0.360g of ethylene glycol antimony were added to the reactor, and the esterification was carried out according to the steps and conditions given in Example 1. After chemical reaction and polycondensation reaction, the material is discharged.

[0051] The intrinsic viscosity [η] of the copolyester is 0.69dL / g; the limiting oxygen index is 37.5; the vertical combustion level is V-0, and there is no droplet from two ignition to extinguishment in vertical combustion; cone calorimetry test The peak heat release rate PHRR is 363kW / m 2 , the total smoke release TSR is 1443m 2 / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com