Antistatic PVC (polyvinyl chloride) sheet material

An antistatic and antistatic agent technology, applied in the field of polymer material preparation, can solve problems such as hindering application, prone to static charge, explosion or fire, etc., to achieve the effect of suppressing static electricity, inhibiting the accumulation of static electricity, and reducing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

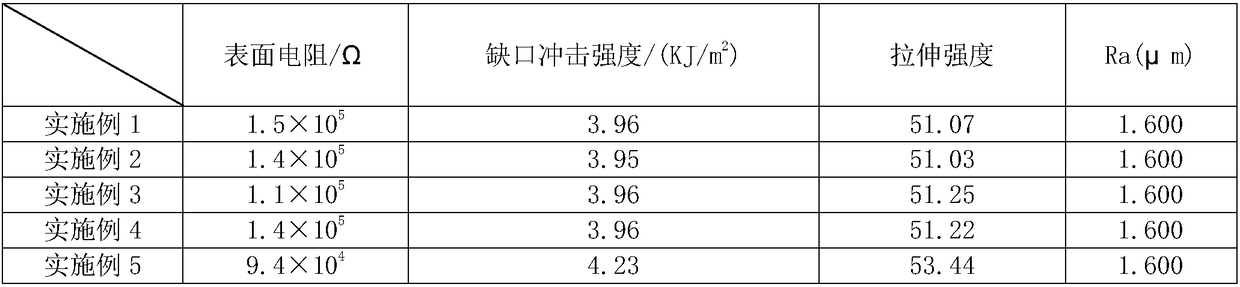

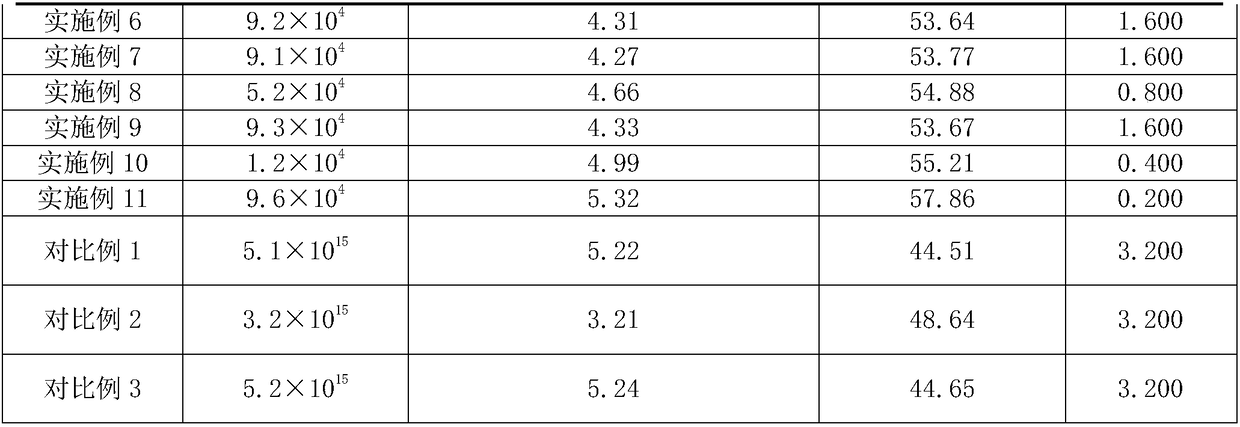

Embodiment 1

[0019] Example 1: An antistatic PVC sheet, the components and their contents in the raw materials are shown in Table 1, and the unit of each component in Table 1 is kg. Wherein the lubricant is microcrystalline paraffin, the stabilizer is methyl tin sulfate, and the filler is calcium carbonate.

[0020] The production process of antistatic PVC sheet is as follows, step 1, batching, take each component in the raw material, heat to 85°C, and stir evenly. Step 2, extruding, cooling the material in step 1 to 50°C, feeding it into an extruder for extrusion, controlling the heating temperature of the extruder at 140-150°C, and controlling the plasticizing temperature of the material at 150-180°C. Step 3, calendering, the material extruded by the extruder is calendered with a calender, and the temperature of the calendering roller is controlled between 150-170°C. Step 4, cooling and winding, the PVC sheet calendered by the calender is cooled and rolled to obtain an antistatic PVC sh...

Embodiment 2

[0021] Example 2: An antistatic PVC sheet, the difference from Example 1 is that the components and contents in the raw materials are as shown in Table 1. Wherein the lubricant is calcium stearate, the stabilizer is butyl tin, and the filler is aluminum oxide.

Embodiment 3

[0022] Example 3: An antistatic PVC sheet, the difference from Example 1 is that the components and their contents in the raw materials are as shown in Table 1. The lubricant is glycerol monooleate, the stabilizer is octyltin, and the filler is silicon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com