Electric flocculation deep treatment method for thallium-containing wastewater and electric flocculation device

A treatment method and technology of a treatment device, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as numerous process steps, achieve simple process flow, convenient disassembly and assembly, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

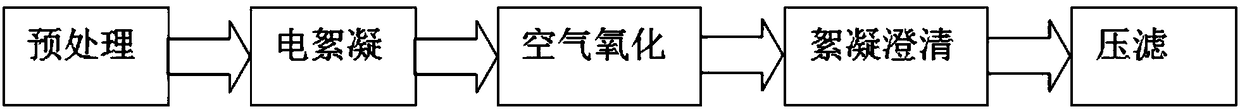

[0043] Such as figure 1 As shown, an electro-flocculation advanced treatment method for thallium-containing wastewater includes the following steps:

[0044] (1) Add 50g / m to wastewater containing thallium 3 TMT series precipitants are pretreated to obtain pretreated wastewater with finer particles containing heavy metal ions;

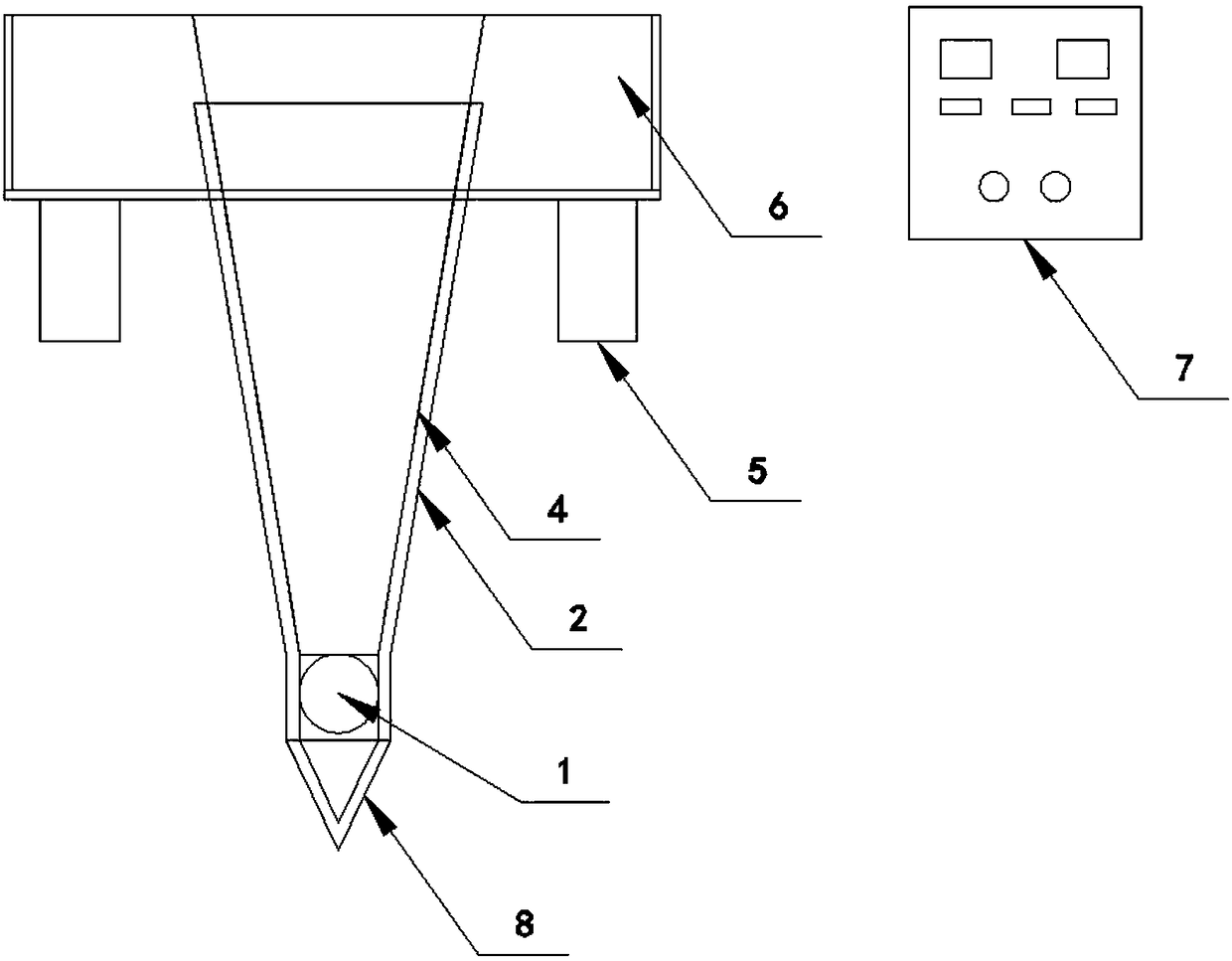

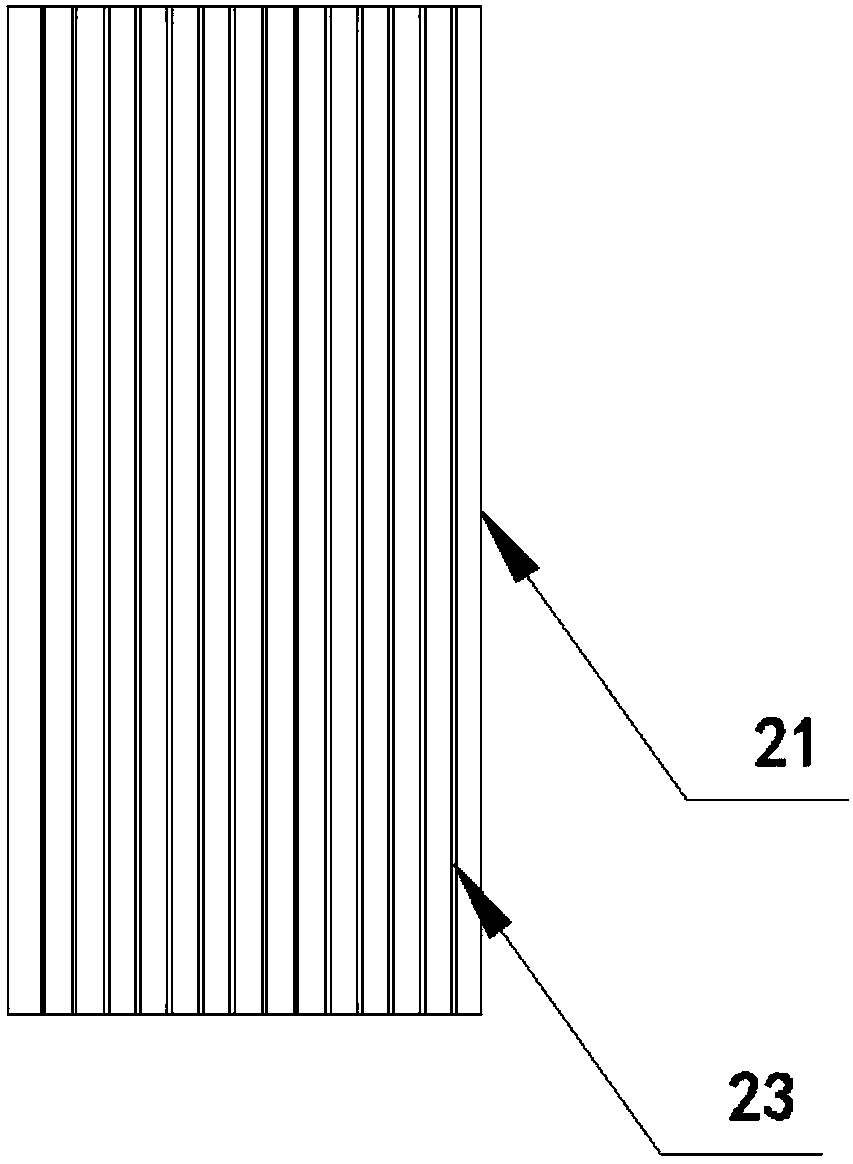

[0045] (2) Treat the pretreated wastewater in step (1) with an electric flocculation treatment device to obtain electric flocculation treatment wastewater;

[0046] (3) Put the electro-flocculation treatment wastewater obtained in step (2) in the air for 15 minutes to obtain oxidation treatment wastewater;

[0047] (4) Add 2g / m to the oxidation treatment wastewater obtained in step (3) 3 The flocculant PAM is filtered after flocculation and sedimentation, and the filtrate is directly discharged.

[0048] The thallium-containing wastewater in this embodiment is wastewater from a manganese tetroxide plant in Shanxi, and its composition and common parameters are as...

Embodiment 2

[0058] A method for advanced treatment of thallium-containing wastewater by electro-flocculation includes the following steps:

[0059] (1) Add 30g / m to wastewater containing thallium 3 Pretreatment with precipitant sodium sulfide to obtain finer particles of pretreated wastewater containing heavy metal ion solid matter;

[0060] (2) Treat the pretreated wastewater in step (1) with an electric flocculation treatment device to obtain electric flocculation treatment wastewater;

[0061] (3) Put the electro-flocculation treatment wastewater obtained in step (2) in the air for 15 minutes to obtain oxidation treatment wastewater;

[0062] (4) Add 2g / L of flocculant PAM to the oxidation treatment wastewater obtained in step (3), flocculate and settle and filter, and the filtrate is directly discharged.

[0063] The thallium-containing wastewater in this embodiment is wastewater from a zinc-based product smelter in Chenzhou. Its composition and common parameters are as follows: thallium: 58.6u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com