Metallographic phase corrosive liquid for austenitic stainless steel as well as preparation and corrosion methods thereof

A technology of austenitic stainless steel and corrosive solution, which is applied in the field of metallographic corrosive solution of austenitic stainless steel and its preparation and corrosion. It can solve the problems of unknown corrosion effect, unsatisfactory corrosion effect, and poor stability of corrosive solution. The effect of corrosion time is easy to grasp, difficult to observe, and corrosion speed is slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

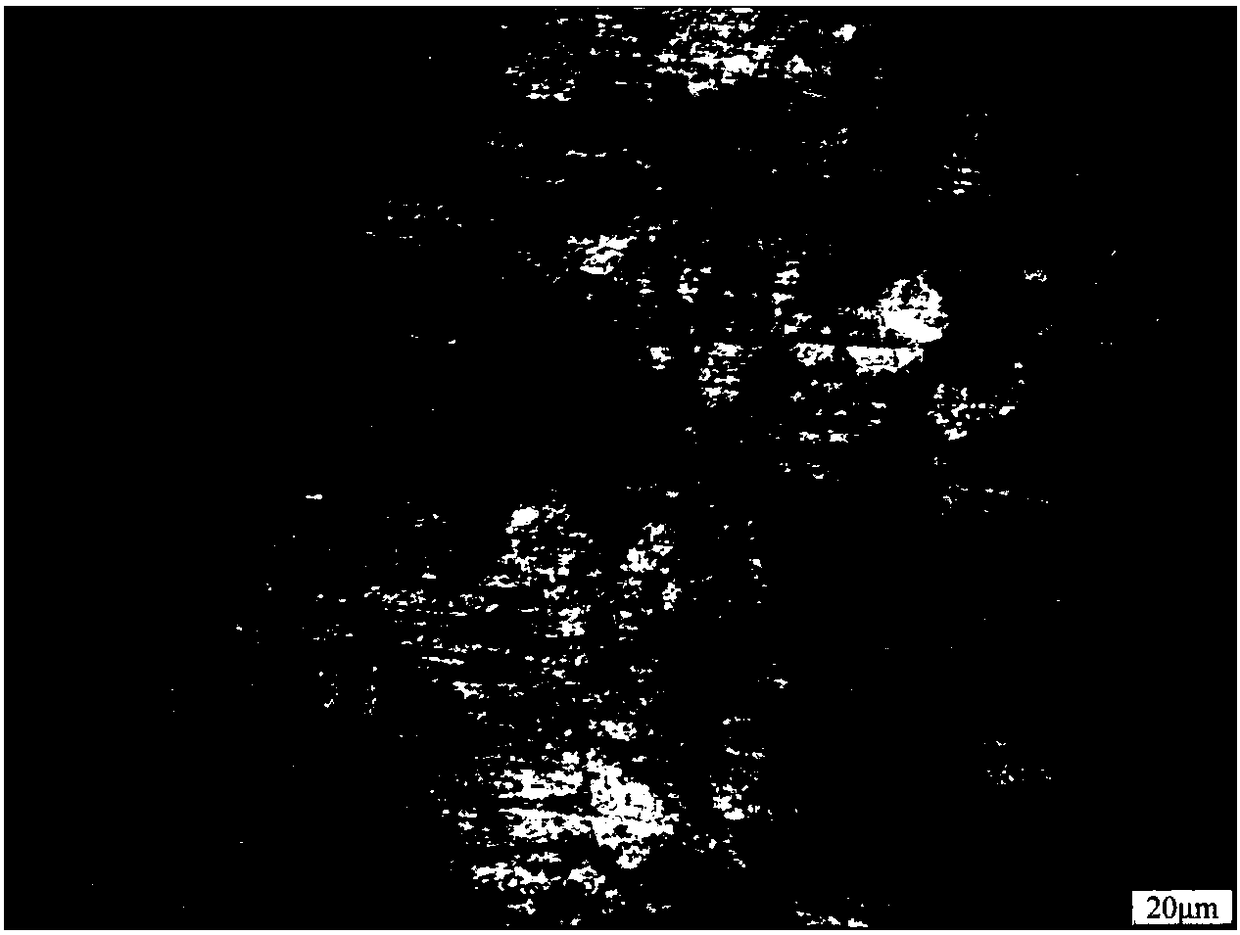

Image

Examples

Embodiment 1

[0049] The metallographic etching solution of this embodiment is 1ml boric acid, 14ml nitric acid, 8ml hydrofluoric acid and 77ml distilled water.

[0050] Pour an appropriate amount of soft tap water or distilled water into a 500mL rough-mouthed plastic bottle, then add anhydrous sodium carbonate and stir until saturated and dissolved to prepare a saturated alkaline neutralizing solution. Seal the prepared saturated lye with a lid for later use.

[0051] Sample: A new type of high-temperature fatigue-resistant austenitic stainless steel (commercially available), whose composition is based on ordinary 304L with 0.35% Cu, 0.15Mo, 0.03Nb, and 0.25Co added.

[0052] Sample treatment: Grind the test surface of the sample with 180#, 600#, 800#, 1000#, 1200# water sandpaper in turn, and then polish it to a mirror surface without scratches, then rinse it with clean water, spray it with absolute ethanol and dry it.

[0053] Corrosion solution preparation: at room temperature, pour 77...

Embodiment 2

[0057] The metallographic etching solution of this embodiment is 1ml boric acid, 15ml nitric acid, 7ml hydrofluoric acid and 77ml distilled water.

[0058] Pour an appropriate amount of soft tap water or distilled water into a 500mL rough-mouthed plastic bottle, then add anhydrous sodium carbonate and stir until saturated and dissolved to prepare a saturated alkaline neutralizing solution. Seal the prepared saturated lye with a lid for later use.

[0059] Corrosion solution preparation: at room temperature, pour 77ml of distilled water into a beaker, pour 7ml of hydrofluoric acid, 15ml of concentrated nitric acid and 1ml of boric acid into the beaker in turn, stir gently with a stirring rod, then let it stand for 2 minutes to configure as described Metallographic etchant.

[0060] Sample: 3.5mm new high-temperature fatigue-resistant austenitic stainless steel, whose composition is based on ordinary 304L with 0.25% Cu, 0.16Mo, 0.04Nb, 0.25Co added. Sample treatment: Grind the...

Embodiment 3

[0064] The metallographic etching solution of this embodiment is 2ml boric acid, 14ml nitric acid, 7ml hydrofluoric acid and 77ml distilled water.

[0065] Pour an appropriate amount of soft tap water or distilled water into a 500mL rough-mouthed plastic bottle, then add anhydrous sodium carbonate and stir until saturated and dissolved to prepare a saturated alkaline neutralizing solution. Seal the prepared saturated lye with a lid for later use.

[0066] Sample: 2mm solution-treated new high-temperature fatigue-resistant austenitic stainless steel cold-rolled steel plate, whose composition is based on ordinary 304L with 0.25% Cu, 0.16Mo, 0.04Nb, 0.25Co added.

[0067] Sample treatment: Grind the test surface of the sample with 180#, 600#, 800#, 1000#, 1200# water sandpaper in turn, and then polish it to a mirror surface without scratches, then rinse it with clean water, spray it with absolute ethanol and dry it.

[0068] Corrosion solution preparation: at room temperature, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com