Metallographic corrosive liquid and metallographic display method of copper-gallium alloy

A copper-gallium alloy and display method technology, which is applied in the field of copper-gallium alloy metallographic corrosion solution, can solve the problems of high cost and difficulty in controlling the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

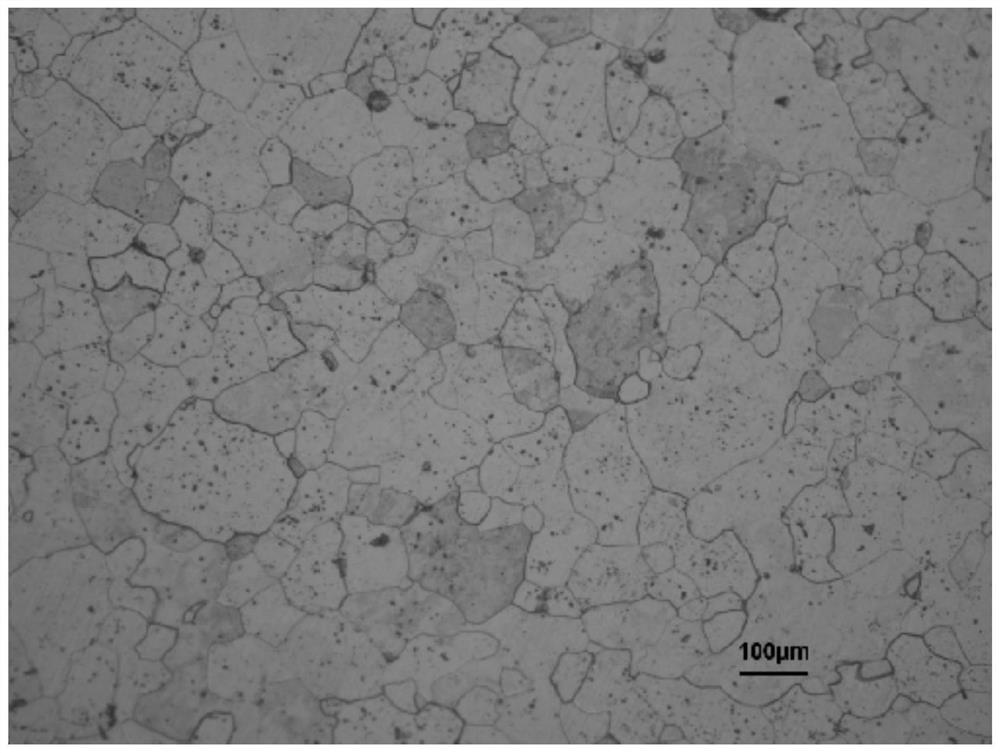

Embodiment 1

[0051] The mass fraction ratio of the copper-gallium alloy in this embodiment is Ga: Cu (Wt%)=20:80

[0052] (a) Cut the copper-gallium alloy into a square sample with a size of 12mm*12mm*25mm; this size is more convenient to hold and thus easy to operate;

[0053] (b) The first stage of grinding: choose 300-mesh sandpaper and install it on the grinding machine, use water as the wetting agent for grinding, select the 12mm*12mm surface as the grinding surface, the speed of the grinding machine is 150r / min, and the grinding time is 15 minutes; The cutting marks on the grinding surface can be polished off;

[0054] (c) The second stage of grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 600 mesh, and the grinding direction of the sample is 90° to the scratches of the first stage of grinding Angle, the speed of the grinder is 150r / min, continue to grind the grinding surface, and the grinding time is 15 minutes;

[0055] (d) The third...

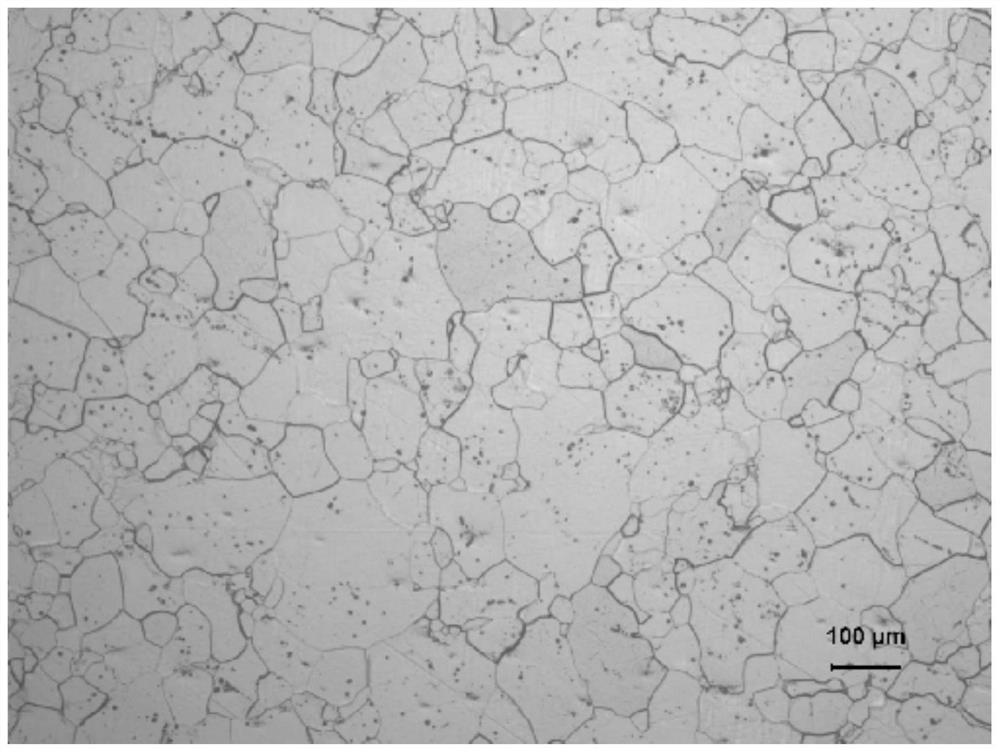

Embodiment 2

[0062] The mass fraction ratio of the copper-gallium alloy of this embodiment is Ga: Cu (Wt%)=45:55

[0063] (a) Cut the copper-gallium alloy into a square sample with a size of 5mm*5mm*15mm; this size is more convenient to hold and thus easy to operate;

[0064] (b) The first stage of grinding: select 60-mesh sandpaper and install it on the grinding machine, use water as the wetting agent for grinding, select the 5mm*5mm surface as the grinding surface, the speed of the grinding machine is 100r / min, and the grinding time is 5 minutes; The cutting marks on the grinding surface can be polished off;

[0065] (c) The second stage of grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 500 mesh, and the grinding direction of the sample is 60° from the scratches of the first stage of grinding Angle, the speed of the grinder is 100r / min, continue to grind the grinding surface, and the grinding time is 5 minutes;

[0066] (d) The third stag...

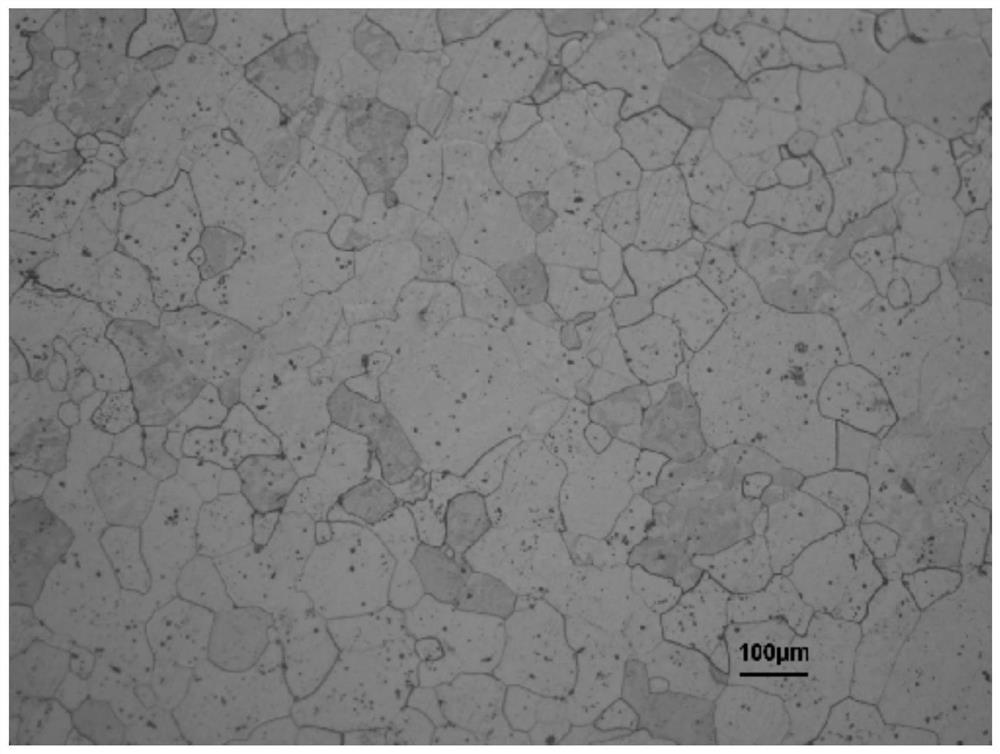

Embodiment 3

[0073] The mass fraction ratio of the copper-gallium alloy in this embodiment is Ga:Cu(Wt%)=10:90

[0074] (a) Cut the copper-gallium alloy into a square sample with a size of 20mm*20mm*45mm; this size is more convenient to hold and thus easy to operate;

[0075] (b) The first stage of grinding: choose 400-mesh sandpaper and install it on the grinding machine, use water as the wetting agent for grinding, select the 20mm*20mm surface as the grinding surface, the speed of the grinding machine is 200r / min, and the grinding time is 20 minutes; The cutting marks on the grinding surface can be polished off;

[0076] (c) The second stage of grinding: wash the sample with clean water, replace the sandpaper on the grinding machine with 900 mesh, and the grinding direction of the sample is 120° from the scratches of the first stage of grinding Angle, the speed of the grinder is 200r / min, continue to grind the grinding surface, and the grinding time is 20 minutes;

[0077] (d) The thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com