A kind of nano-rod-shaped manganese-chromium composite oxide low-temperature denitrification catalyst and its preparation method

A composite oxide and nanorod-shaped technology, applied in the field of flue gas denitrification, can solve the problems of complex preparation process, high denitration temperature, narrow activity window, etc., and achieve the effects of simple preparation process, high activity, and promotion of formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 0.3 g of potassium permanganate and 0.25 g of chromium nitrate in 40 ml of deionized water, and ultrasonically disperse to obtain chromium nitrate solution and potassium permanganate solution.

[0024] (2) Mix the chromium nitrate solution and the potassium permanganate solution evenly, and magnetically stir for 2 hours at room temperature to obtain a mixed solution.

[0025] (3) Transfer the mixed liquid prepared in step (2) to a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100 ml, and react at 170° C. for 4 h.

[0026] (4) Suction filtration and washing of the solution in step (3), drying at 60°C, and calcining at 400°C for 3h in a muffle furnace to obtain a nanorod-shaped manganese-chromium composite oxide catalyst ((n-r)MnCrO X )(4h)).

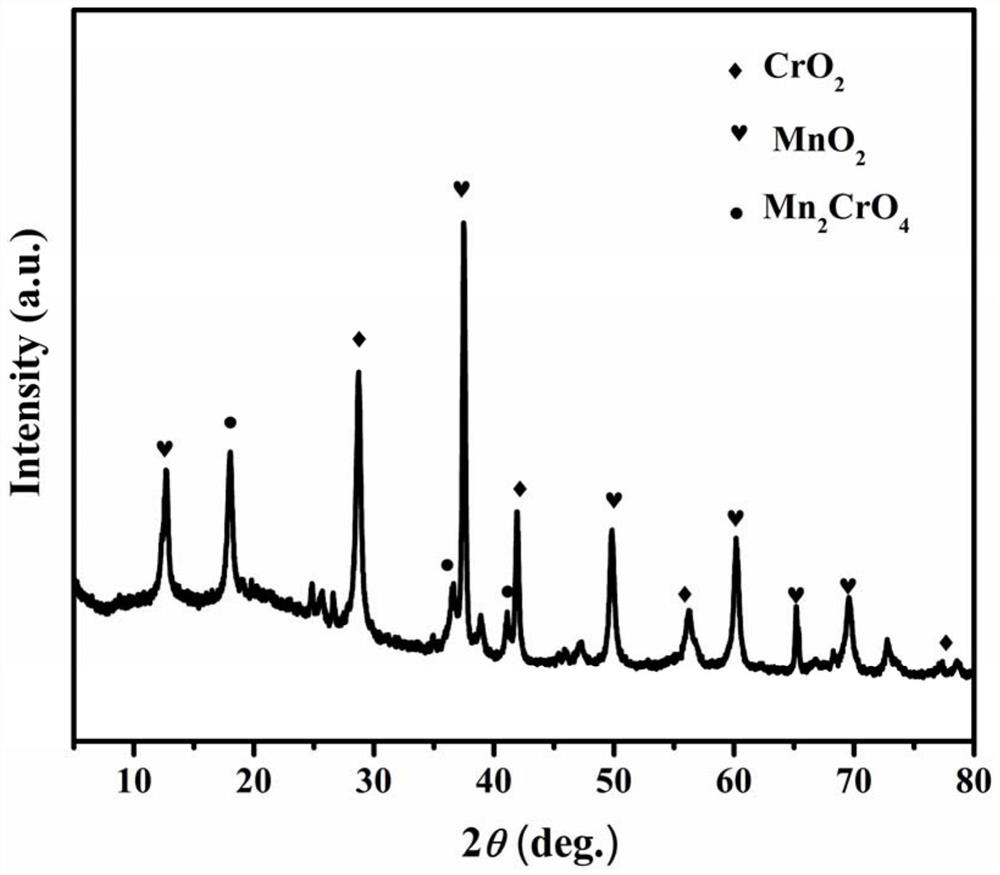

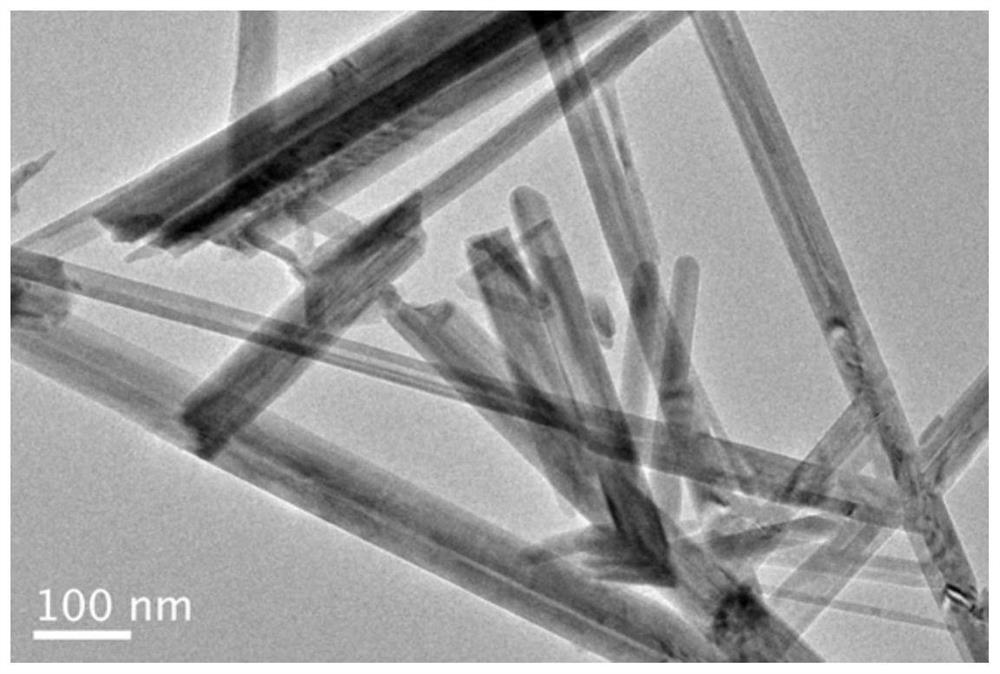

[0027] figure 1 ((n-r)MnCrO prepared for Example 1 X ) XRD diagram. It can be seen from the figure that the nanorod-shaped manganese-chromium composite oxide mainly contains oxides of mangan...

Embodiment 2

[0030] (1) Dissolve 0.3 g of potassium permanganate and 0.25 g of chromium nitrate in 40 ml of deionized water, and disperse ultrasonically to obtain chromium nitrate solution and potassium permanganate solution.

[0031] (2) Mix the chromium nitrate solution and the potassium permanganate solution evenly, and magnetically stir for 2 hours at room temperature to obtain a mixed solution.

[0032] (3) Transfer the mixed solution prepared in step (2) to a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100 ml, and react at 170° C. for 2 h.

[0033] (4) Suction filtration and washing of the solution in step (3), drying at 80°C, and calcining for 3h at 400°C in a muffle furnace to obtain a nanorod-shaped manganese-chromium composite oxide catalyst (((n-r)MnCrO X )(2h)).

Embodiment 3

[0035] (1) Dissolve 0.3 g of potassium permanganate and 0.25 g of chromium nitrate in 40 ml of deionized water, and disperse ultrasonically to obtain chromium nitrate solution and potassium permanganate solution.

[0036] (2) Mix the chromium nitrate solution and the potassium permanganate solution evenly, and magnetically stir for 2 hours at room temperature to obtain a mixed solution.

[0037] (3) Transfer the mixed liquid prepared in step (2) to a polytetrafluoroethylene hydrothermal kettle with a volume capacity of 100 ml, and react at 170° C. for 6 h.

[0038] (4) Suction filtration and washing of the solution in step (3), drying at 100°C, and calcining for 3h at 400°C in a muffle furnace to obtain a nanorod-shaped manganese-chromium composite oxide catalyst (((n-r)MnCrO X )(6h)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com