Composite SCR denitration catalyst and preparation method thereof

A technology of denitration catalyst and denitration rate, which is applied in the field of composite SCR denitration catalyst and its preparation, can solve the problem that catalysts and low temperature catalysts cannot adapt to temperature fluctuations, etc., and achieve the effects of reducing software investment costs and equipment investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

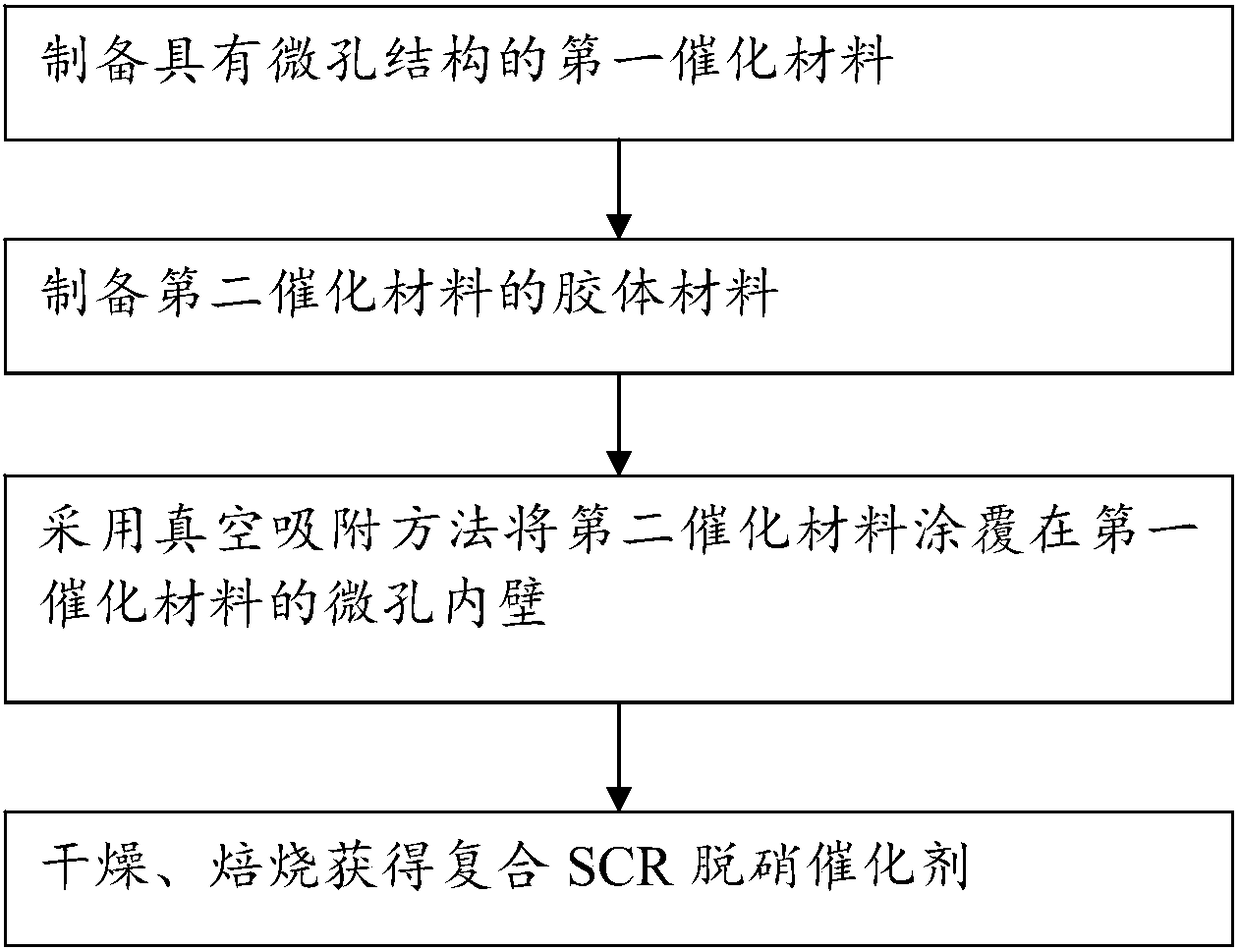

[0041] combine figure 1 As shown, the embodiment of the present application also discloses a preparation method of a composite SCR denitration catalyst, including:

[0042] (1), preparing the first catalytic material with a microporous structure; wherein the calcination temperature is 500-650°C, and the time is 20-35h,

[0043] (2), preparing the colloidal material of the second catalytic material;

[0044] (3), adopting the vacuum adsorption method to coat the second catalytic material on the micropore inner wall of the first catalytic material;

[0045] (4) drying and roasting to obtain a composite SCR denitration catalyst.

[0046] In a preferred embodiment, in step (4), the drying condition is 80-120° C., and the drying time is 1-5 hours.

[0047] In a preferred embodiment, in step (4), the calcination condition is 400-500°C, and the calcination time is 3-8 hours.

[0048] Due to the composite preparation of conventional temperature catalysts and low temperature coatin...

Embodiment 1

[0051] (1) Preparation of the first catalytic material (conventional temperature catalyst, optimal denitrification temperature 300-420°C)

[0052] The preparation of conventional temperature catalysts is realized by means of compounding, extrusion molding, drying and roasting.

[0053] Among them, the raw materials include:

[0054] 60 parts of titanium dioxide;

[0055] 0.5 parts of ammonium metavanadate;

[0056] 3 parts of ammonium metatungstate;

[0057] 6 parts glass fiber;

[0058] 2 parts wood pulp

[0059] 1.5 parts of binder;

[0060] 3 parts of silicon dioxide;

[0061] 2 parts wollastonite;

[0062] Deionized 20 parts;

[0063] 8 parts of ammonia water.

[0064] When preparing conventional temperature catalysts, it is especially necessary to adjust the microstructure of the product. By controlling the temperature during calcination, the material itself will be sintered if the temperature is too high, causing the micropores to collapse and the pore size to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com