Method for pre-enriching precious metal mineral in baiyuneboite

A technology for medium and precious metals in Obo Mine, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of resource waste environment, complex mineral processing process, cumbersome operation, etc., achieve good results, good economic benefits, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

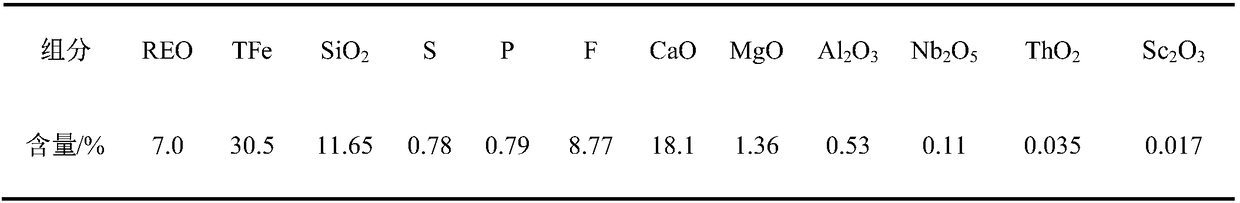

[0033] The multi-element analysis results of the raw ore of Baiyun Obo Mine in this embodiment are shown in Table 1.

[0034] Table 1 Multi-element analysis of raw ore

[0035]

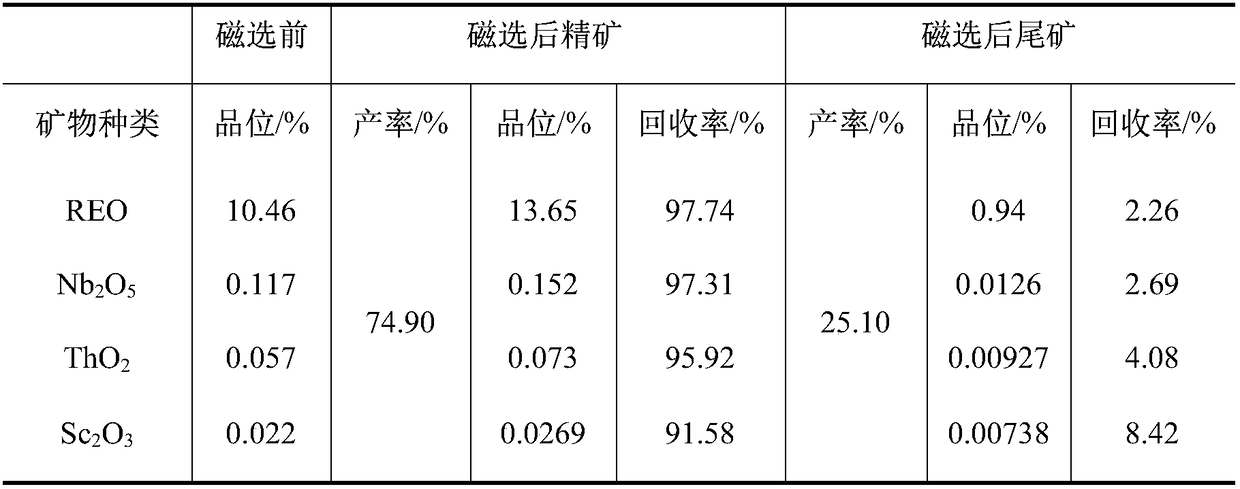

[0036] The raw ore of Baiyan Obo Mine was used as the ore for the experiment, and it was crushed to 88% below 0.074mm in one stage, followed by two stages of weak magnetic separation with a magnetic field strength of 3000GS and 7000GS to remove the strong magnetic minerals in the ore, and then the obtained weak magnetic Minerals are pulverized in two stages to 80% below 0.045mm, and mixed with water to obtain a pulp with a mass concentration of 20%, adding a dispersant sodium silicate 2500g / t of weak magnetic minerals, and sending it into a superconducting magnetic separation with a magnetic field strength of 3.0T In the separation chamber of the superconducting magnetic separator, magnetic separation is carried out. The flow rate of the ore pulp in the separation chamber of the superconducting mag...

Embodiment 2

[0042] The multi-element analysis results of the raw ore of Baiyun Obo Mine in this embodiment are shown in Table 3.

[0043] Table 3 Multi-element analysis of raw ore

[0044]

[0045]The raw ore of Baiyan Obo Mine was used as the ore for the experiment, crushed to 90% below 0.074mm in one stage, followed by two stages of weak magnetic separation with a magnetic field strength of 3000GS and 8000GS to remove the strong magnetic minerals in the ore, and then the obtained weak magnetic Minerals are pulverized in two stages to 80% below 0.045mm, and mixed with water to obtain a pulp with a mass concentration of 25%, adding a dispersant sodium hexametaphosphate 1000g / t weak magnetic minerals, and sending it into a superconducting magnetic field with a magnetic field strength of 3.5T. Magnetic separation is carried out in the separation chamber of the separator. The flow rate of the ore pulp in the separation chamber of the superconducting magnetic separator is 3.5cm / s, the puls...

Embodiment 3

[0051] The multi-element analysis results of the tailings of Baiyun Obo Mine in this example are shown in Table 5.

[0052] Table 5 Multi-element analysis of tailings

[0053]

[0054] The tailings of Baiyan Obo Mine were used as the ore for the experiment, crushed to 88% below 0.074mm in one stage, and then separated by a magnetic separator with a magnetic field strength of 8000GS to remove the strong magnetic minerals in the ore, and then the obtained weak magnetic minerals were subjected to secondary Segment crushing to 80% below 0.045mm, add water and stir to obtain a pulp with a mass concentration of 35%, add a dispersant sodium oxalate 1500g / t weak magnetic minerals, and send it to a superconducting magnetic separator with a magnetic field strength of 4.0T for separation In the cavity, magnetic separation is carried out. The flow rate of the ore pulp in the separation cavity of the superconducting magnetic separator is 2.0cm / s, and the pulse frequency is 100 times / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com