Movable type active heave compensator and working method thereof

A heave compensation and mobile technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc., can solve the problem of low compensation accuracy of passive compensators, immature semi-active heave Loss, energy loss and other issues, to achieve the effect of simple structure, saving design and transformation costs, no throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

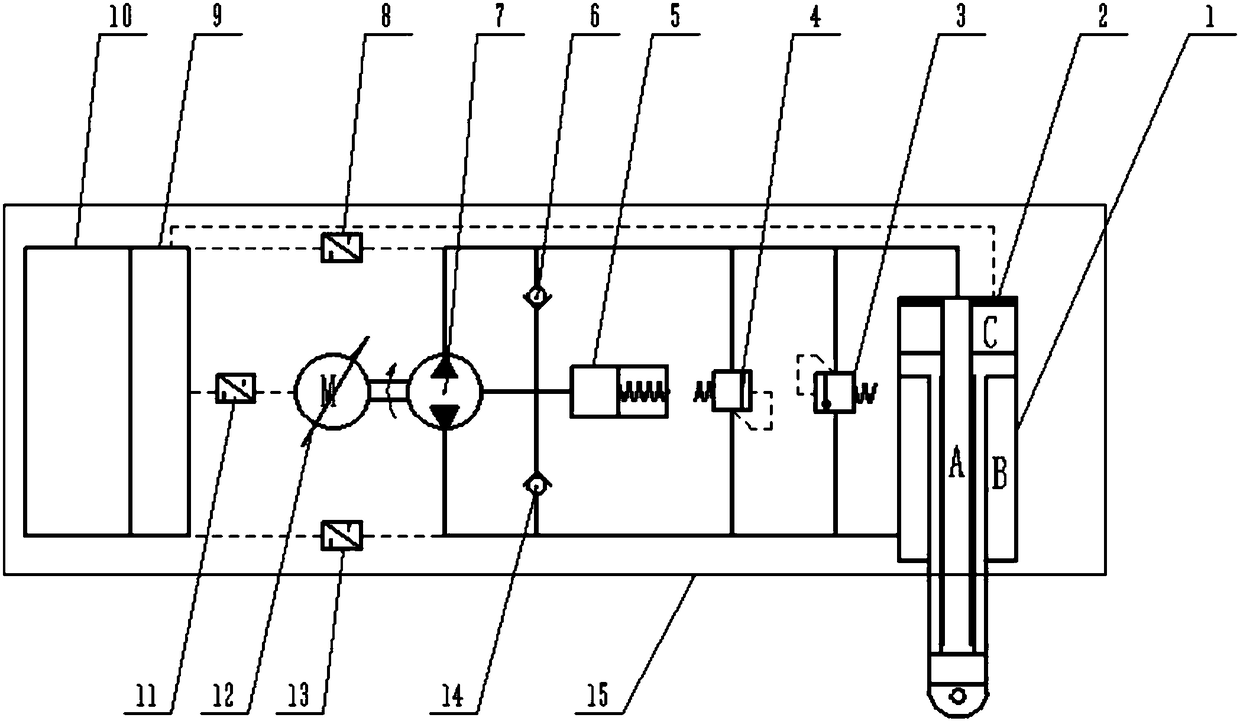

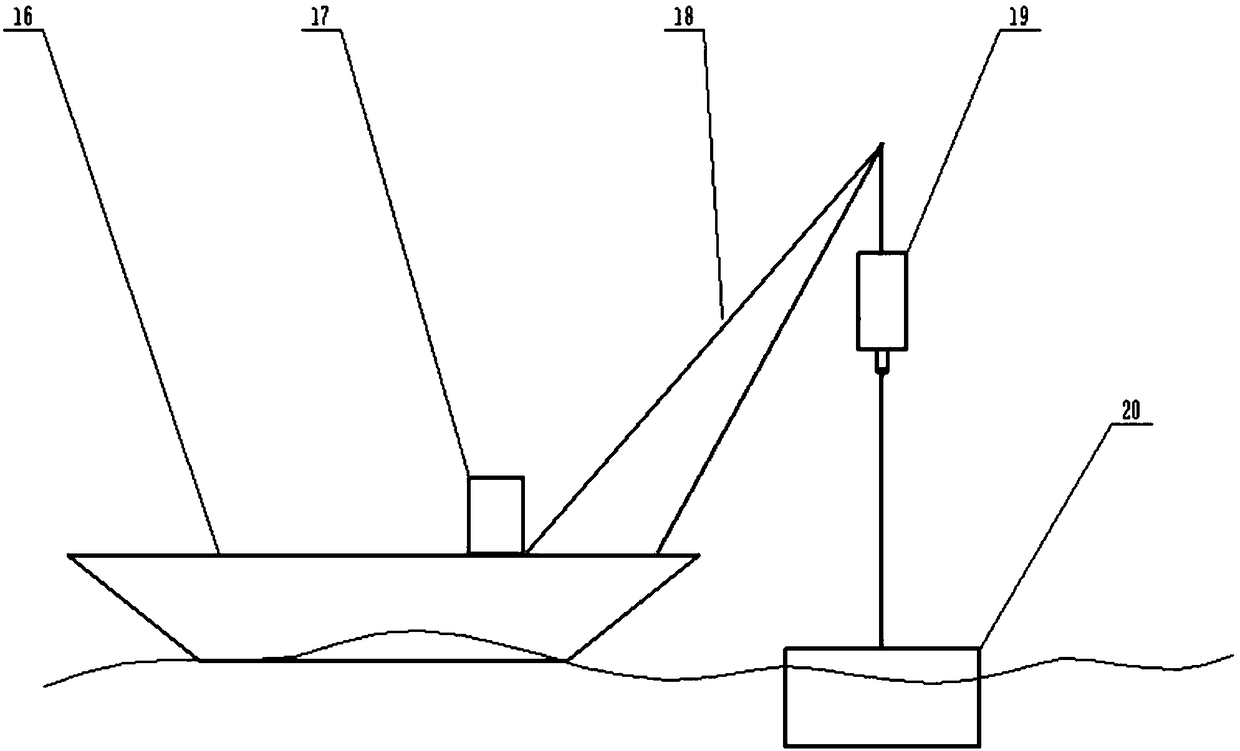

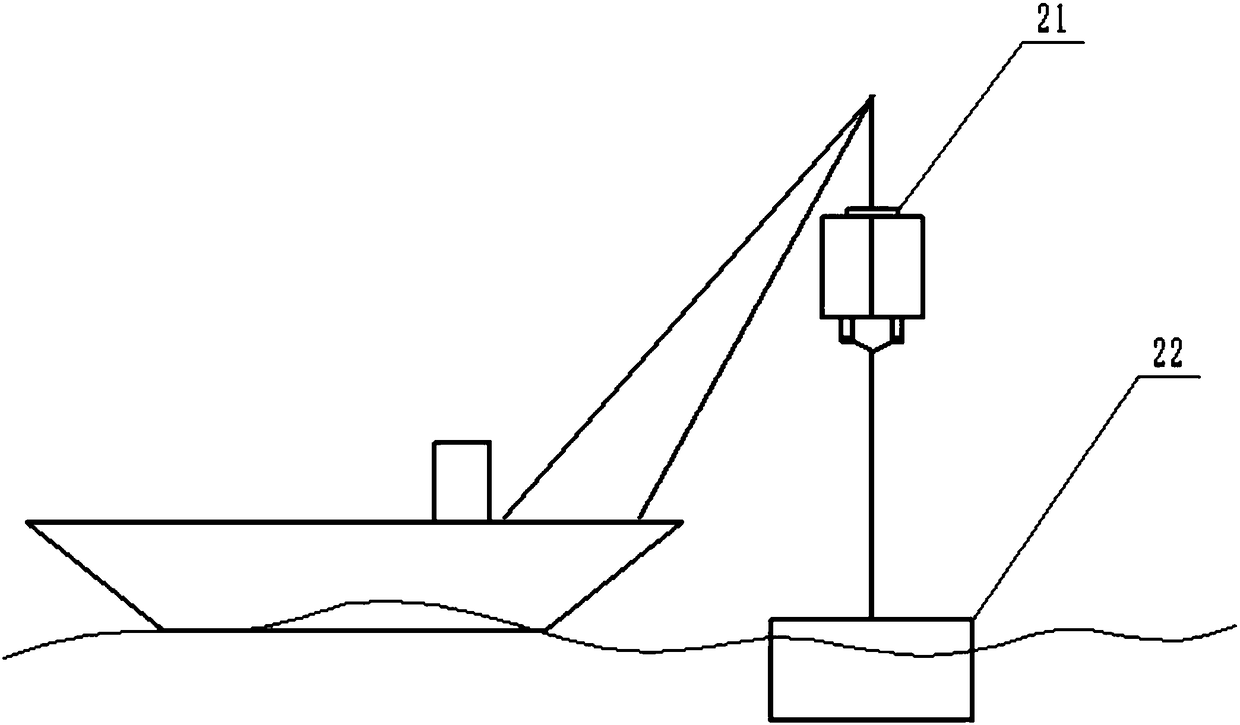

[0048] A mobile active heave compensator, comprising a differential hydraulic cylinder 1, a bidirectional quantitative pump 7, a servo motor 12, a controller 9, and a power supply; the controller 9 is connected to the servo motor 12, and the controller is used to receive external signals and control the servo The start-stop and speed of the motor; the servo motor 12 is connected with the two-way quantitative pump 7, and the servo motor is used to control the pumping of the two-way quantitative pump; the differential hydraulic cylinder 1 includes two chambers, respectively A chamber and B chamber, one of which is The cavity is connected to the piston rod, such as figure 1 The chamber A shown; the two ends of the two-way quantitative pump are respectively connected to the chamber A and chamber B of the differential hydraulic cylinder through the oil circuit, which is used to extract the oil in chamber A or chamber B in both directions; the power supply is used to supply the two-w...

Embodiment 2

[0051] A mobile active heave compensator, the structure of which is as described in Embodiment 1, the difference is that the area of cavity A of the differential hydraulic cylinder is equal to the area of cavity B, and the differential hydraulic cylinder is also provided with a vacuum cavity, Such as figure 1 C chamber in.

Embodiment 3

[0053] A mobile active heave compensator, the structure of which is as described in Embodiment 2, the difference is that a built-in laser displacement sensor 2 is provided in the differential hydraulic cylinder. The built-in laser displacement sensor is used to feedback the displacement value of the expansion and contraction of the piston rod. The built-in laser displacement sensor is arranged on the cavity wall of the vacuum cavity. Do not mix with oil chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com