Preparation method of modified metal-organic framework and composite nano-filtration membrane

A metal-organic framework, composite nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of stable membrane structure, low cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

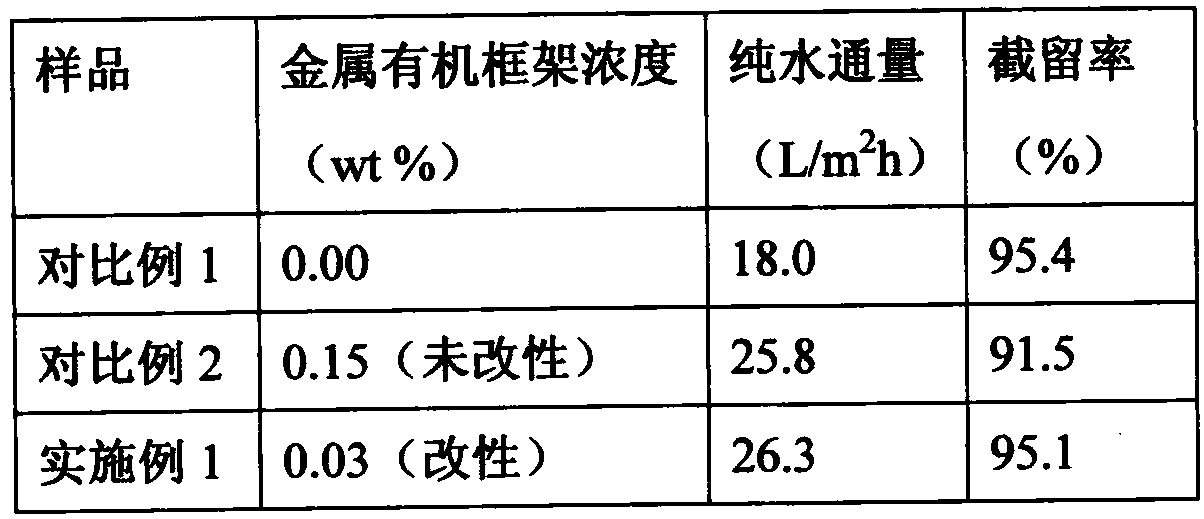

[0024] A preparation method of a composite nanofiltration membrane containing a modified metal-organic framework:

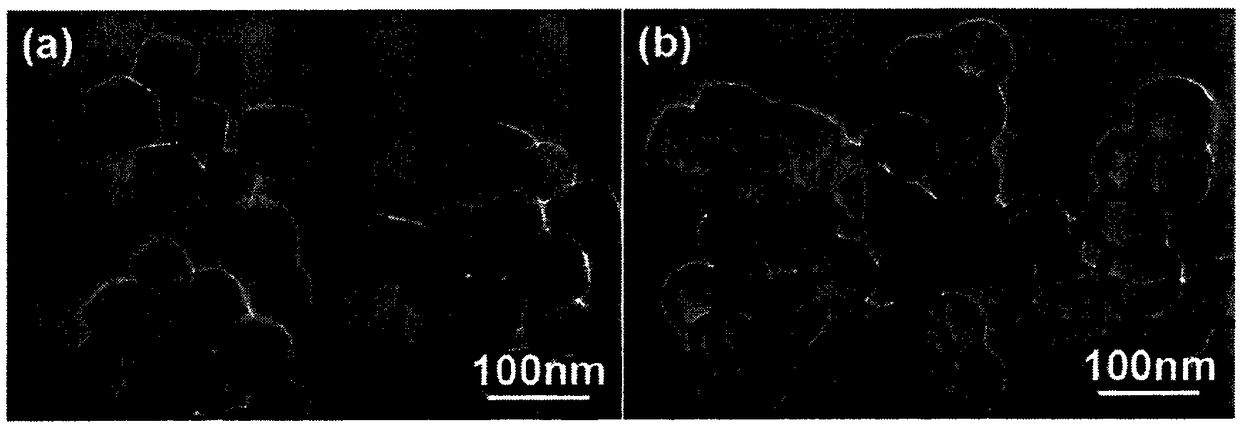

[0025] (1) Add 500 mg of ZIF-8 (a type of metal-organic framework) into 200 mL of an aqueous solution containing 3 mg / mL of tannic acid (TA), and react with rapid stirring for 5 min. Then, centrifuge to obtain the precipitate, wash the precipitate with deionized water several times, and freeze-dry to obtain the modified metal-organic framework (ZIF-8@TA);

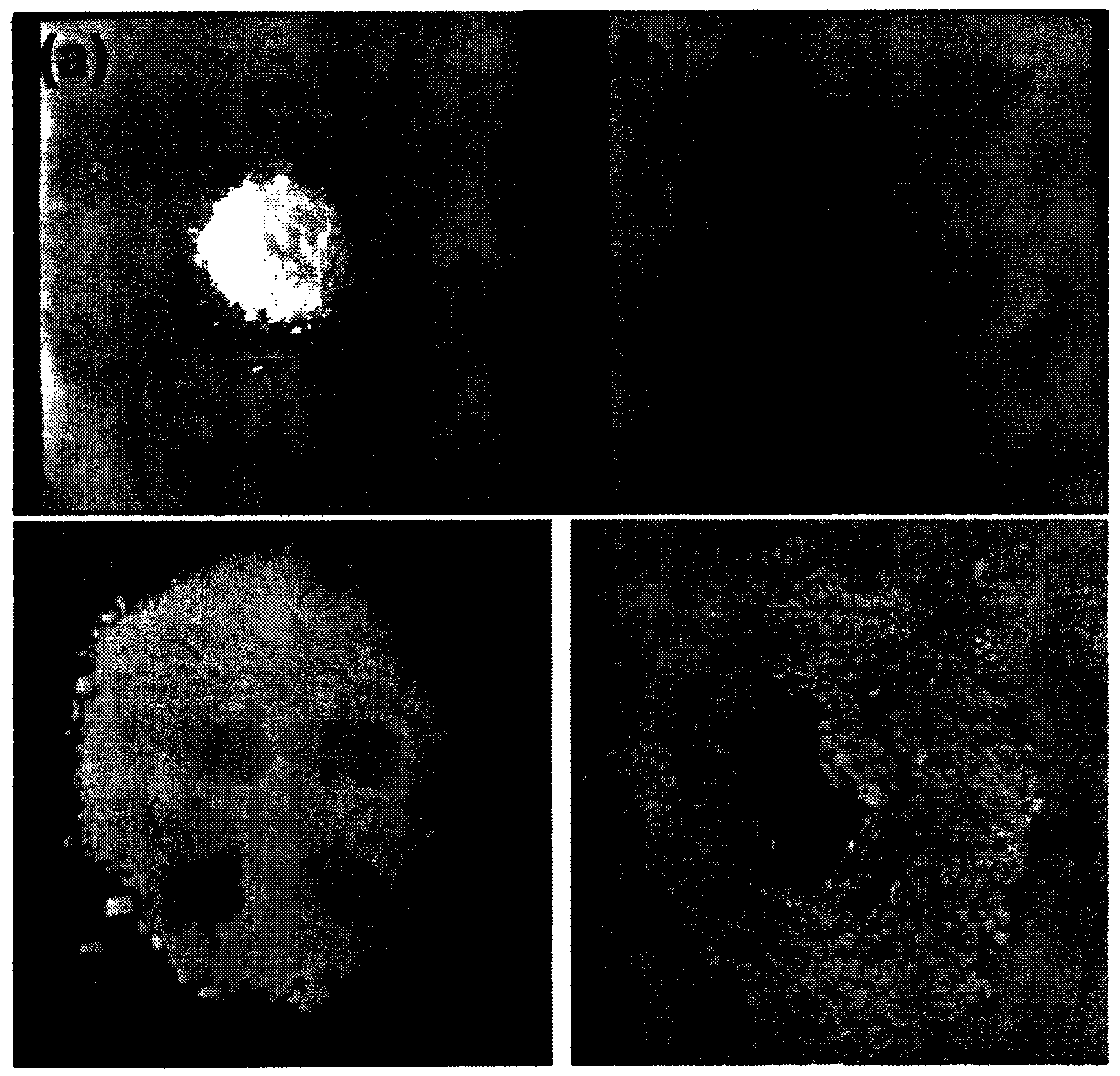

[0026] (2) Preparation of aqueous phase solution: Dissolve 0.5wt% piperazine and 0.2wt% sodium hydroxide in deionized water, then add ZIF-8@TA with a concentration of 0.03wt%, and disperse it by ultrasonication for 5 minutes Uniform; immerse the wet polysulfone support membrane in the water phase solution for 5 minutes, take it out, roll the surface of the support membrane with a rubber roller, and squeeze it dry;

[0027] (3) Preparation of the oil phase solution: Dissolving trimesoyl chloride with a concent...

Embodiment 2

[0030] A preparation method of a composite nanofiltration membrane containing a modified metal-organic framework:

[0031] (1) Add 500 mg of ZIF-8 (a type of metal-organic framework) into 200 mL of an aqueous solution containing 3 mg / mL of tannic acid (TA), and react with rapid stirring for 5 min. Then, centrifuge to obtain the precipitate, wash the precipitate with deionized water several times, and freeze-dry to obtain the modified metal-organic framework (ZIF-8@TA);

[0032] (2) Preparation of aqueous phase solution: Dissolve 0.5wt% piperazine and 0.2wt% sodium hydroxide in deionized water, then add ZIF-8@TA with a concentration of 0.06wt%, and disperse it by ultrasonication for 5 minutes Uniform; immerse the wet polysulfone support membrane in the water phase solution for 5 minutes, take it out, roll the surface of the support membrane with a rubber roller, and squeeze it dry;

[0033] (3) Preparation of the oil phase solution: Dissolving trimesoyl chloride with a concent...

Embodiment 3

[0036] A preparation method of a composite nanofiltration membrane containing a modified metal-organic framework:

[0037] (1) Add 500 mg of ZIF-8 (a type of metal-organic framework) into 200 mL of an aqueous solution containing 3 mg / mL of tannic acid (TA), and react with rapid stirring for 5 min. Then, centrifuge to obtain the precipitate, wash the precipitate with deionized water several times, and freeze-dry to obtain the modified metal-organic framework (ZIF-8@TA);

[0038] (2) Preparation of aqueous phase solution: Dissolve 0.5wt% piperazine and 0.2wt% sodium hydroxide in deionized water, then add 0.10wt% ZIF-8@TA, and disperse it by ultrasonication for 5 minutes Uniform; immerse the wet polysulfone support membrane in the water phase solution for 5 minutes, take it out, roll the surface of the support membrane with a rubber roller, and squeeze it dry;

[0039] (3) Preparation of the oil phase solution: Dissolving trimesoyl chloride with a concentration of 0.10 wt% in n-he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com