Method for preparing resistance heating element

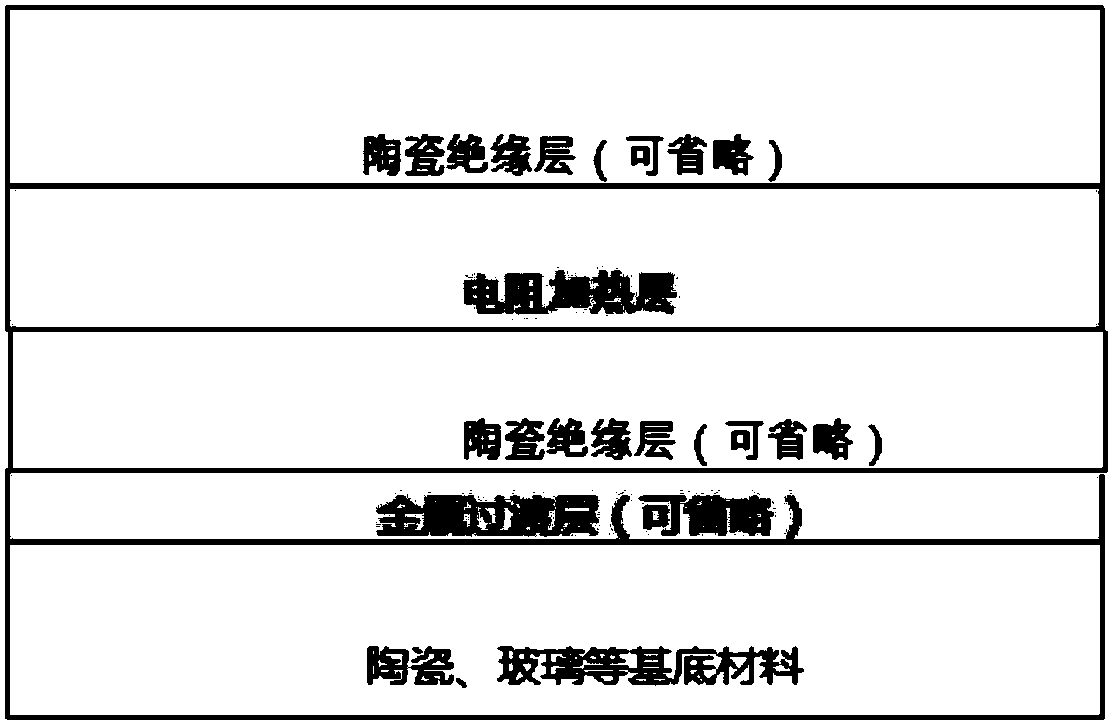

A resistance heating element and resistance heating technology, applied in the direction of ohmic resistance heating, electrical components, additive manufacturing, etc., can solve the problems of high porosity and oxide content in the resistance heating layer, difficulty in obtaining materials, and limited application range, etc., to achieve Excellent environmental protection benefits, convenient heating temperature and heating power, and the effect of precise control of heating temperature and heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

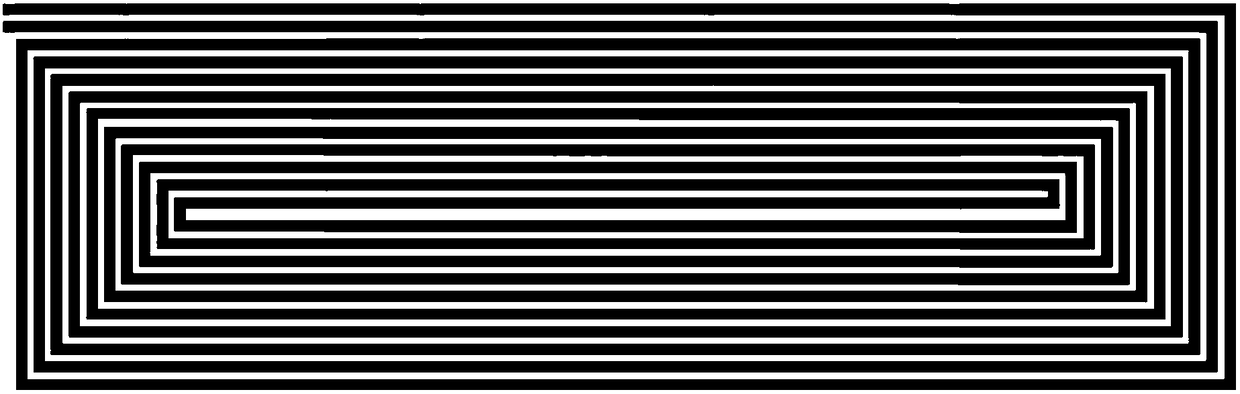

[0031] Such as Figure 3a As shown, a resistive heating layer is fabricated on a ceramic substrate:

[0032] (1) Cleaning is performed on an alumina ceramic sheet with a size of 200x100 mm and a thickness of 2 mm, followed by sandblasting and roughening with corundum, so that the surface of the area to be deposited by spraying has become rough.

[0033] (2) The material is NiCr alloy (Ni80%, Cr20%), the material is made into powder by argon atomization method, sieved and dried, the particle size is 10-50 microns, and then SLM is used, laser beam power: 400W, scanning Speed: 1700mm / s, 3D printing deposits to form a serpentine pattern, and obtains a ceramic sheet with a resistance heating layer.

[0034] (3) Then use silver-copper brazing material to weld the copper leads to the two terminals of the resistance layer to form a usable ceramic-based heating chip.

[0035] If the heating plate needs to be insulated, a 100-200 micron thick aluminum oxide coating can be deposited on...

Embodiment 2

[0037] Such as Figure 3b As shown, the resistive heating layer is fabricated on the epoxy resin substrate:

[0038] (1) Clean the epoxy resin sheet with a size of 200x100 mm and a thickness of 4 mm, and then use white corundum to sandblast and roughen it, so that the surface of the area that needs to be sprayed and deposited has become rough.

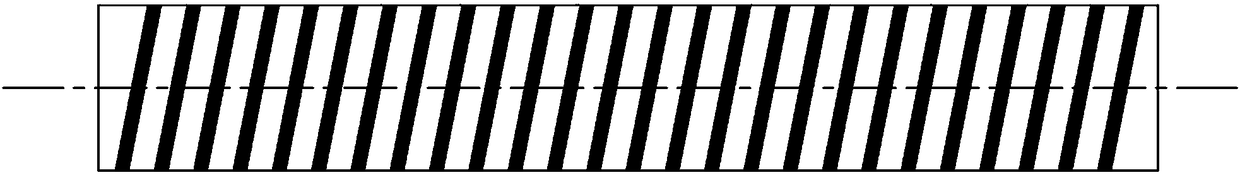

[0039] (2) Since the plastic substrate is easily deformed, melted or carbonized during the high-temperature spraying process, first use cold spraying or arc spraying to deposit a 5-10 micron thick zinc layer on the surface (the first layer can also be deposited directly on the plastic Turn down the power a bit, and the plastic will melt slightly, which can improve the bonding force between the plastic and the resistance layer). Then the material is NiCr alloy (Ni80%, Cr20%), the material is made into powder by argon atomization method, sieved and dried, the particle size is 10-50 microns, and then SLM is used, laser beam power: 400W, ...

Embodiment 3

[0043] Such as Figure 3c As shown, make a resistive heating layer on the copper sheet:

[0044] (1) Clean the copper sheet with a size of 200x100mm and a thickness of 4mm, and then use corundum to blast and roughen it, so that the surface of the area that needs to be sprayed and deposited has become rough.

[0045] (2) First adopt the plasma spraying method to deposit a 5-10 micron thick aluminum oxide insulating layer on the surface. The material is NiCr alloy (Ni80%, Cr20%), the material is made into powder by argon atomization method, sieved and dried, the particle size is 50-150 microns, and then laser cladding is carried out. Laser beam power: 3kW, laser beam spot diameter : Scanning speed: 10mm / min, powder flow range: 10g / min, high-purity argon as a protective atmosphere, forming a serpentine pattern, and obtaining a copper sheet with a resistance heating layer.

[0046] (3) Then use silver-copper brazing material to weld the copper leads to the two terminals of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com