A kind of neodymium-iron-boron magnet containing low-melting-point dysprosium-nickel alloy and its preparation method

A technology of neodymium-iron-boron and nickel alloys, which is applied in the fields of magnetic objects, inductors/transformers/magnets, and magnetic materials. Coercive force, the effect of improving coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

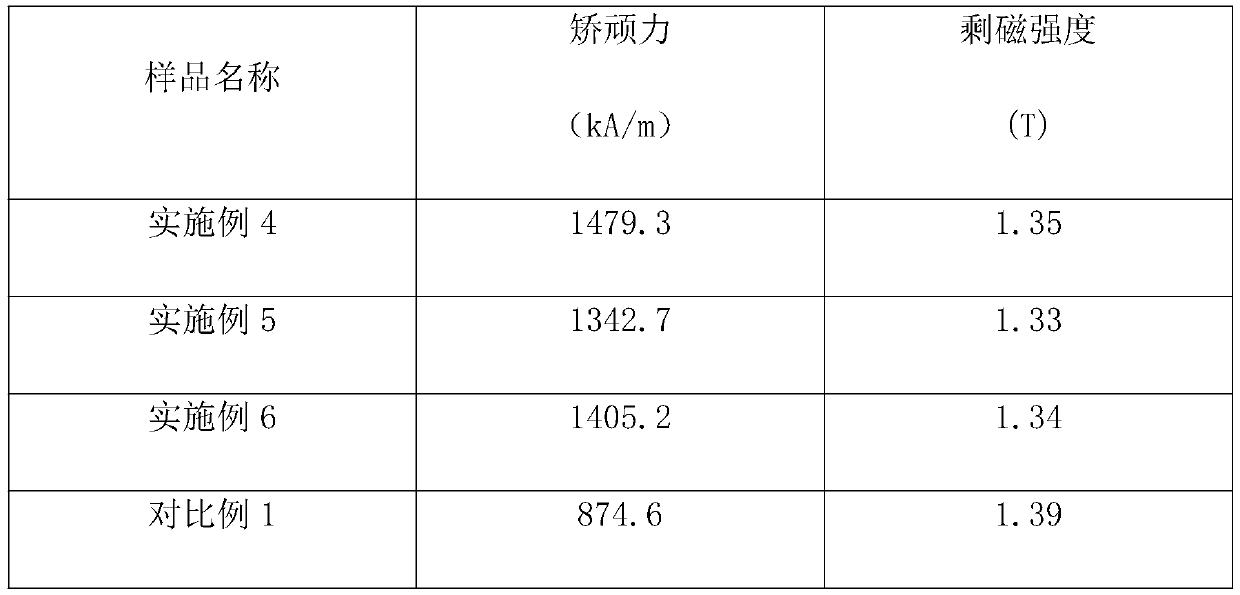

Embodiment 1

[0024] Will Dy 85 Ni 15 (Mass percentage content) The alloy is smelted by an electric arc furnace, then mechanically crushed to coarse particles, and then kerosene is used as a medium to ball-mill the coarse particles into a fine powder of 4 microns. Will prepare Dy 85 Ni 15 Alloy fine powder added to Nd 13.5 Fe 79.75 B 6.75 In the powder, the addition ratio is Nd 13.5 Fe 79.75 B 6.75 4% of powder mass, evenly mixed with DyNi alloy powder. The uniformly mixed powder is subjected to a pulsed magnetic field with a magnetic induction intensity of 4.5T and a pulsed magnetic field of 1200kg / cm 2 Press molding under isostatic pressure to obtain a compact; put the compact into a vacuum sintering furnace, raise the temperature to 1010°C at a rate of 700°C / h, and then rise to 1060°C at 100°C / h. Sintering and heat treatment are performed at 1060°C for 2-4 hours under vacuum, followed by annealing at 900°C for 1 hour, secondary annealing at 650°C for 1 hour, and cooling to fina...

Embodiment 2

[0026] Using Dy 80 Ni 20 , Dysprosium-nickel alloy fine powder with a particle size of 2 microns, and then use the same process as in Example 1 to prepare an NdFeB magnet as a comparative experiment.

Embodiment 3

[0028] Using Dy 70 Ni 30 , Dysprosium-nickel alloy fine powder with a particle size of 1 micron, and then use the same process as in Example 1 to prepare an NdFeB magnet as a comparative experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com