Preparation method of 3D porous nitrogen-doped graphene film electrode

A nitrogen-doped graphene and graphene technology, applied in the field of graphene, can solve the problems of energy storage limitation and reduction of specific surface area, and achieve the effect of high conductivity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

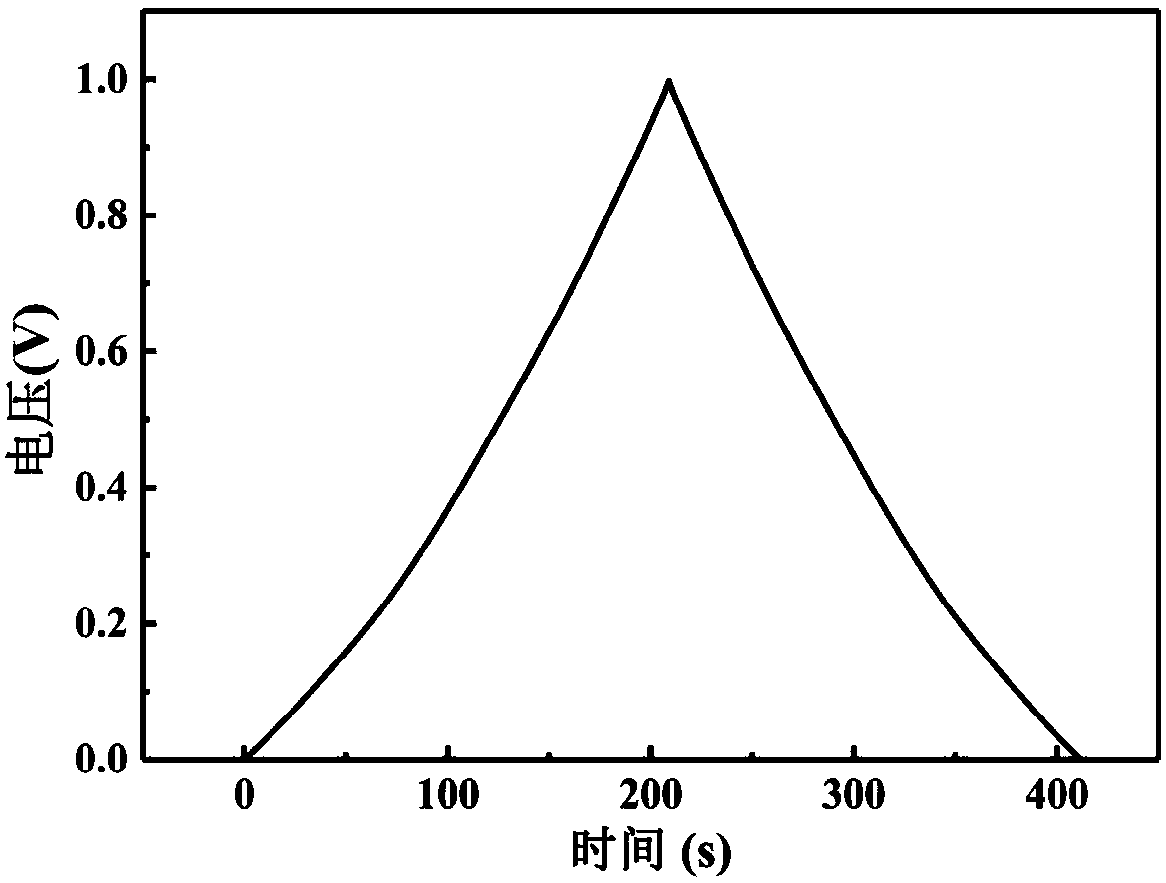

[0024] A kind of preparation method of present embodiment 3D nitrogen-doped graphene film electrode, it comprises the following steps:

[0025] 1) Graphene oxide reduction and nitrogen doping

[0026] Graphene oxide is dissolved in N-N dimethylamide DMF by magnetic stirring, and preparation concentration is the graphene oxide / DMF solution of 1mg / ml; Get appropriate graphene oxide / DMF solution and ethylenediamine according to volume ratio and be 5: 1 After mixing evenly, place it in an oil bath at 85°C under reflux conditions for 8 hours to reduce graphene oxide to prepare a nitrogen-doped graphene solution; use deionized water to repeatedly wash the prepared nitrogen-doped graphene solution until the filtrate is medium Finally, freeze-dry the nitrogen-doped graphene to prepare nitrogen-doped graphene solid.

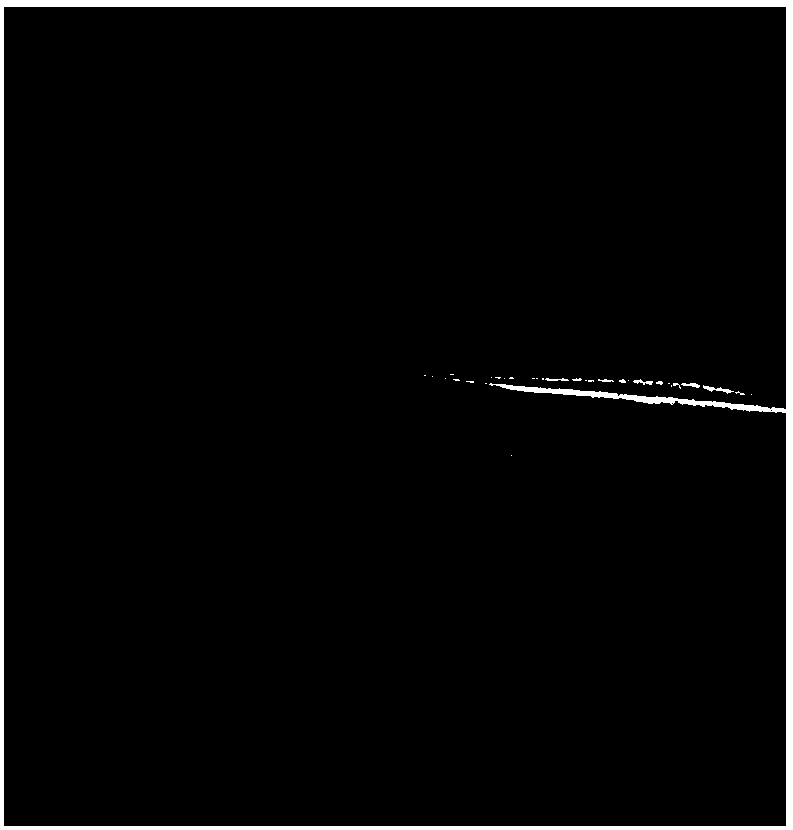

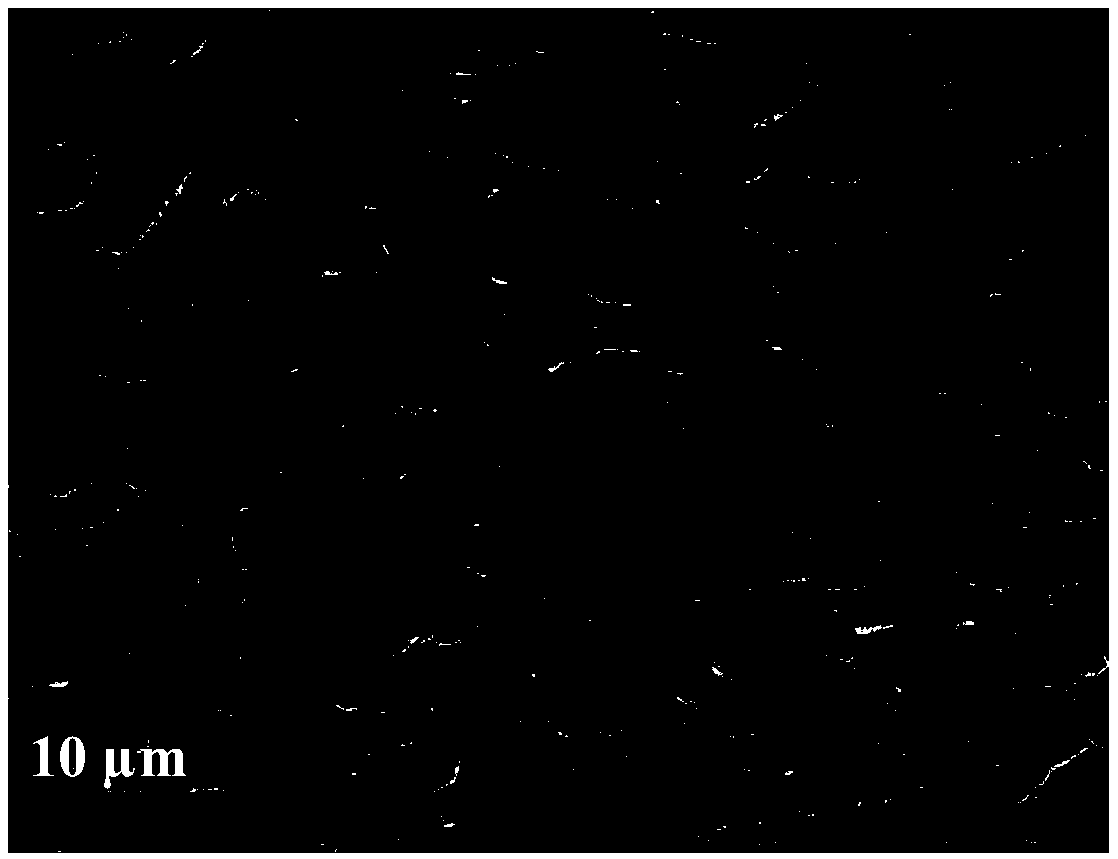

[0027] 2) Preparation of 3D porous nitrogen-doped graphene membrane

[0028] The prepared large flake nitrogen-doped graphene is uniformly stirred and dissolved in etha...

Embodiment 2

[0030] A kind of preparation method of present embodiment 3D nitrogen-doped graphene film electrode, it comprises the following steps:

[0031] 1) Graphene oxide reduction and nitrogen doping

[0032] Graphene oxide is dissolved in N-N dimethylamide DMF by magnetic stirring, and preparation concentration is the graphene oxide / DMF solution of 2mg / ml; Get appropriate graphene oxide / DMF solution and ethylenediamine according to volume ratio and be 3: 1 After mixing evenly, put it in an oil bath at 85°C under reflux conditions for 32 hours, and reduce graphene oxide in one step to prepare a nitrogen-doped graphene solution; use deionized water to repeatedly wash the prepared nitrogen-doped graphene solution until the filtrate is medium Finally, freeze-dry the nitrogen-doped graphene to prepare nitrogen-doped graphene solid.

[0033] 2) Preparation of 3D porous nitrogen-doped graphene membrane

[0034] Mix the prepared large flakes and small flakes of nitrogen-doped graphene acco...

Embodiment 3

[0039] A kind of preparation method of present embodiment 3D nitrogen-doped graphene film electrode, it comprises the following steps:

[0040] 1) Graphene oxide reduction and nitrogen doping

[0041] Graphene oxide is dissolved in N-N dimethylamide DMF by magnetic stirring, and preparation concentration is the graphene oxide / DMF solution of 3mg / ml; Get appropriate graphene oxide / DMF solution and ethylenediamine according to volume ratio and be 1: 1 After mixing evenly, put it in an oil bath at 85°C under reflux conditions for 48 hours, and reduce graphene oxide in one step to prepare a nitrogen-doped graphene solution; use deionized water to repeatedly wash the prepared nitrogen-doped graphene solution until the filtrate is medium Finally, freeze-dry the nitrogen-doped graphene to prepare nitrogen-doped graphene solid.

[0042] 2) Preparation of 3D porous nitrogen-doped graphene membrane

[0043] The prepared small flake nitrogen-doped graphene is uniformly stirred and diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com