Electromagnetic wave type micro casting and liquid forging integrated 3D metal printing machine

An electromagnetic wave and printer technology, which is applied in the field of electromagnetic wave micro-casting solution forging integrated 3D metal printers, can solve the problems of low performance such as durability, toughness and high printing cost, and achieve high cost and high cost. The effect of density and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

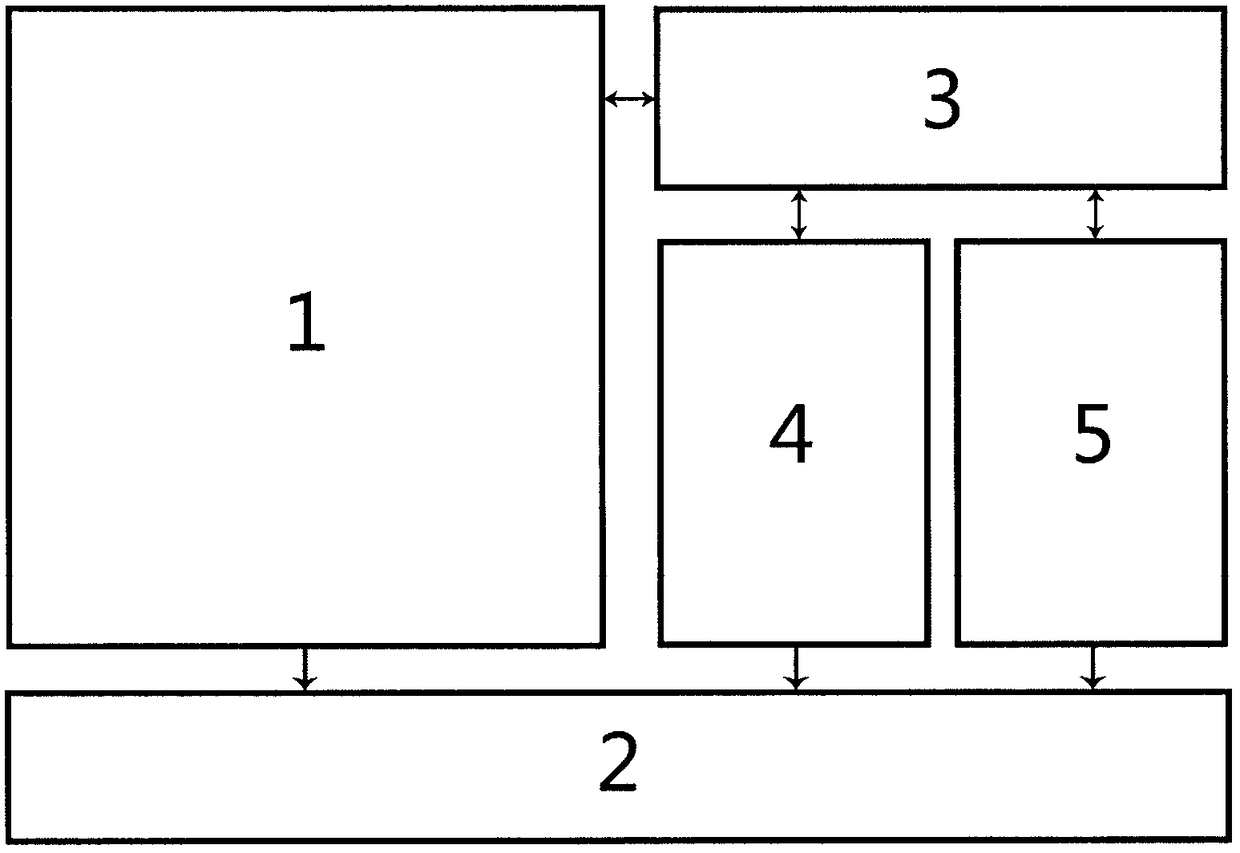

[0019] exist figure 1 Among them, the electromagnetic wave micro-casting liquid forging integrated 3D metal printer consists of a traditional 3D sand mold printer (1), an electromagnetic wave rapid melting metal filling device (4), a micro-casting liquid forging pressure device (5), and an integrated electronic controller ( 3) and the target sand mold (2).

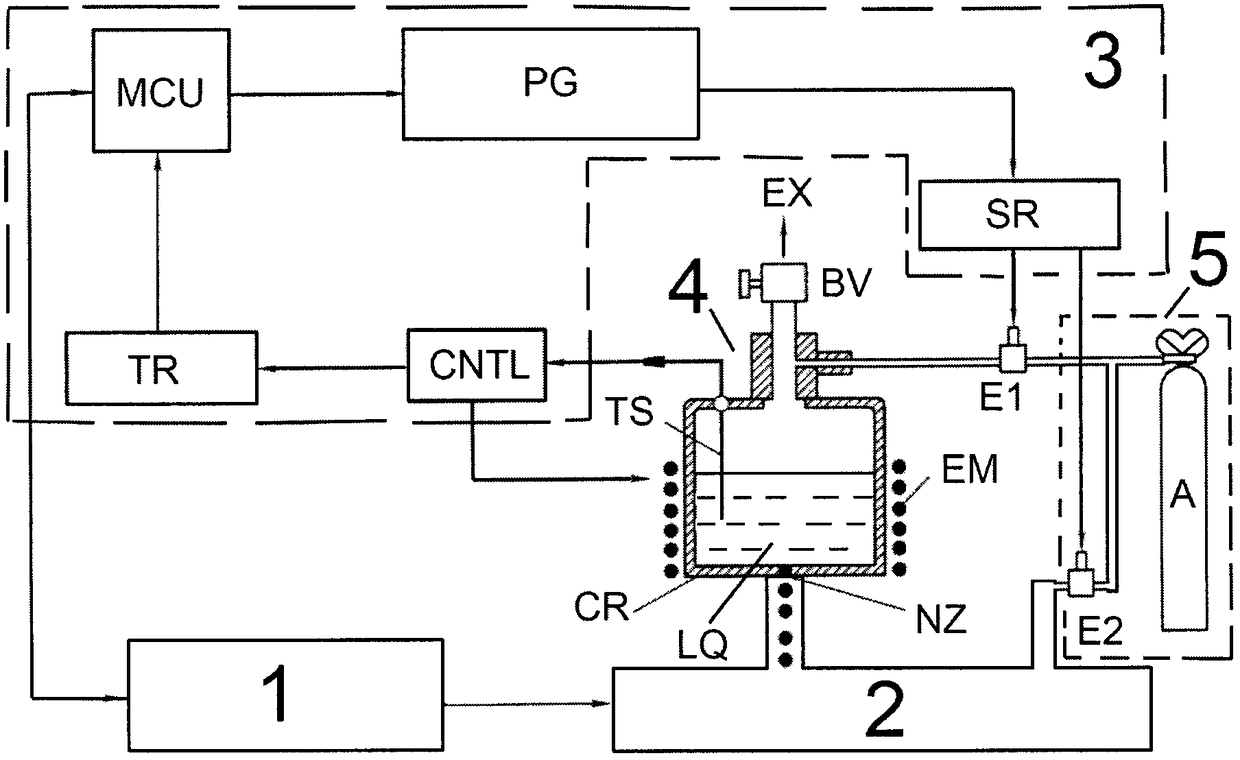

[0020] exist figure 2 In the block diagram of the shown embodiment of the present invention, the integrated electronic controller (3) consists of a main controller (MCU), a pulse generator (PG), a solid state relay (SR), a thermostat (CNTL), a converter (TR); electromagnetic wave fast melting metal filling device (4) consists of nozzle (NZ), crucible (CR), electromagnetic wave sensor (EM), liquid metal or liquid metal matrix composite material (LQ), temperature sensor (TS) , ball valve (BV), exhaust hole (EX), solenoid valve 1 (E1); micro-casting liquid forging pressure device (5) is composed of compressed gas (A), sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com