Method for cooperatively removing heavy metal and organic matters by capacitive deionization coupling electrocatalysis

A technology of capacitive deionization and coupled electricity, which is used in chemical instruments and methods, separation methods, electrochemical water/sewage treatment, etc., to achieve the effect of promoting industrialization, improving removal efficiency, and shortening the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

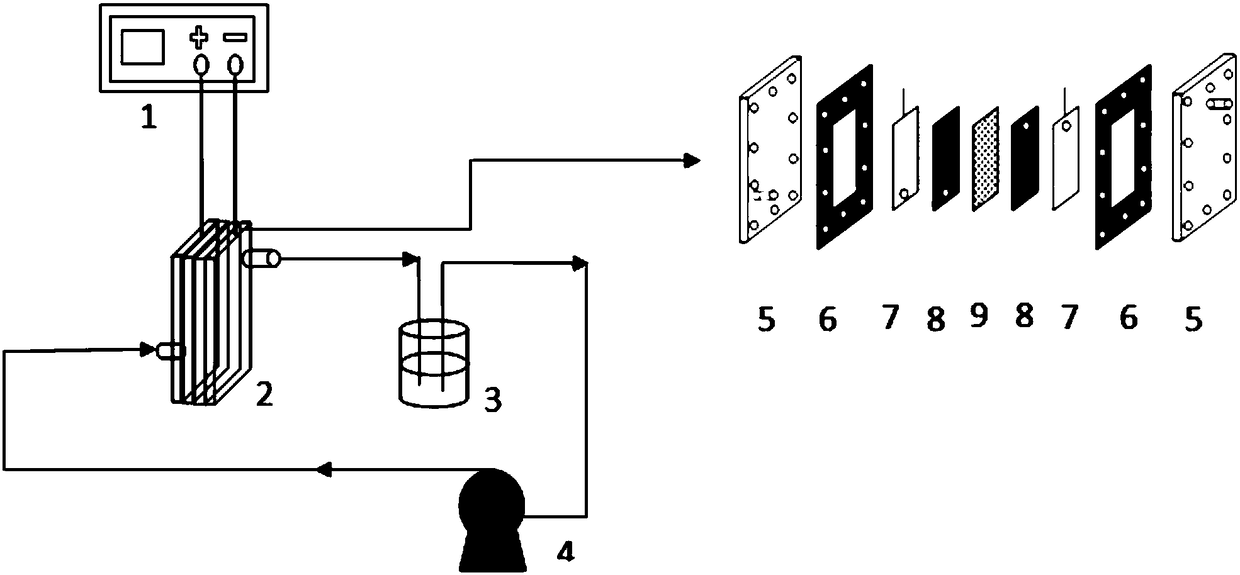

Method used

Image

Examples

Embodiment

[0022] (1) TiO 2 Preparation of sol: Take 14mL tetrabutyl titanate, 16mL absolute ethanol in a beaker, and stir continuously and rapidly for 30min to obtain solution A; take another 8mL absolute ethanol, 2.4mL deionized water, and 1.4mL glacial acetic acid in a beaker , add concentrated HCl dropwise to adjust the pH to 2, which is solution B; while stirring continuously, slowly inject solution B into solution A with a syringe, and stir for about 40 minutes to form TiO 2 Sol.

[0023] (2)TiO 2 Preparation of / ACF electrode: The pretreated activated carbon fiber felt (ACF) was impregnated in TiO with tweezers 2 In the sol, soak for 5 minutes and pull it up, so that the titanium dioxide sol is attached to the carbon felt, dry it at 105 ° C, then soak it, repeat it three times, and dry it; then put the TiO2 2 / ACF is submerged in deionized water, and reacted in a water bath at 95°C for 2 hours. After the reaction is complete, wash off the weak TiO with deionized water 2 , drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com