Ethylbenzene production device and process

A technology of production equipment and production process, which is applied in the field of ethylbenzene production equipment, can solve the problems affecting the purity of reaction products, etc., and achieve the effects of reducing equipment investment, reducing fuel gas consumption, cracking raw materials and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

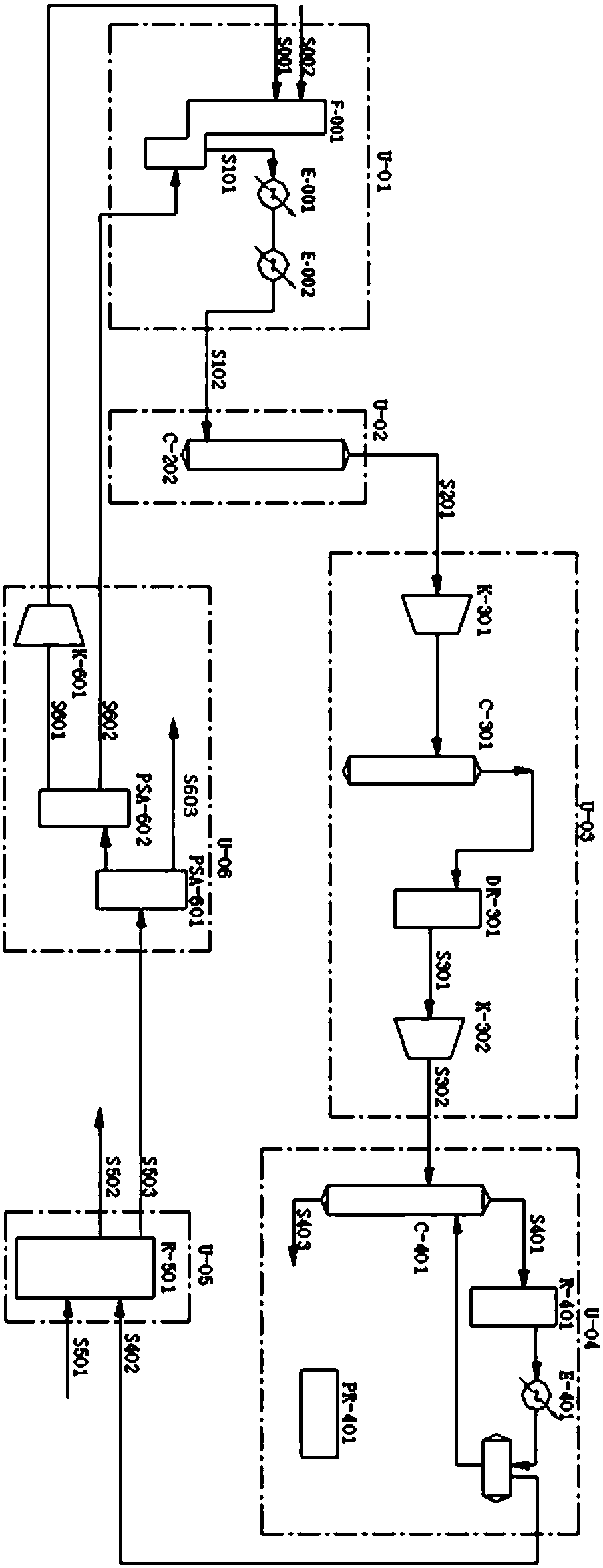

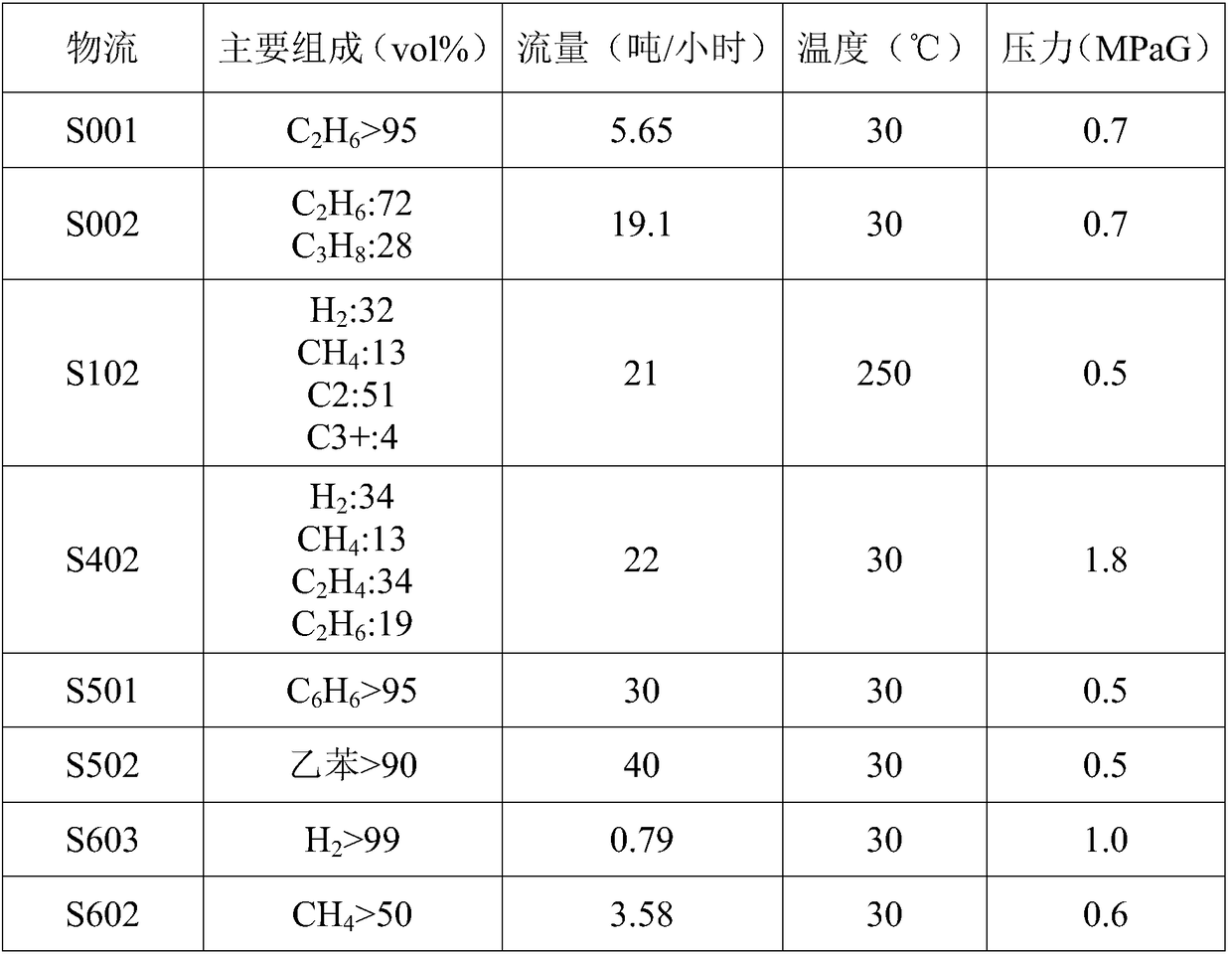

[0020] According to a preferred embodiment of the present invention, the tail gas recovery unit includes a primary pressure swing adsorption system, a secondary pressure swing adsorption system and an ethane booster connected in sequence.

[0021] According to the present invention, the function of the compression unit is to remove acid gas, moisture, etc. in the cracked gas, and to boost the pressure of the treated cracked gas and send it to the cold separation unit. Preferably, the compression unit includes a primary boost compressor, a caustic washing tower, a dryer and a secondary boost compressor connected in sequence.

[0022] Wherein, the alkali scrubbing tower is used to remove acid gas (CO 2 , H 2 S), the dryer is used for dehydration.

[0023] Preferably, the primary boost compressor and the secondary boost compressor are units that share a set of casing and rotor.

[0024] According to the present invention, the cold separation unit includes a deethanizer, a catalytic hydro...

specific Embodiment approach

[0033] According to a specific embodiment, the ethylbenzene production process includes the following processes:

[0034] 1) The circulating cracked raw materials and fresh cracked raw materials are cracked in the cracking furnace of the cracking unit into cracked gas at the outlet of the cracking furnace, and cooled by the heat exchanger to obtain the cooled cracked gas;

[0035] 2) The cooled cracked gas is sent to the quench unit for further cooling to obtain cracked gas at the compressor inlet;

[0036] 3) After the cracked gas at the compressor inlet is boosted by a booster compressor in the compression unit, the acid gas is removed in the caustic washing tower to obtain a boosted deacidified gas and then the cracked gas is dried by a dryer, Send to the secondary booster compressor to boost the pressure again to obtain the cracked gas after the second boost;

[0037] 4) The cracked gas after the second boost is used to remove carbon three or more components in the deethanizer of ...

Embodiment 1

[0053] This embodiment is used to illustrate the ethylbenzene production device and process of the present invention.

[0054] Such as figure 1 As shown, in this embodiment, the primary boost compressor K-301 and the secondary boost compressor K-302 of the compression unit U-03 are units that share a set of casing and rotor.

[0055] The cold capacity of the condenser E-401 in the cold separation unit U-04 is provided by the propylene refrigeration system PR-401.

[0056] The tail gas recovery unit U-06 includes the first-stage pressure swing adsorption system PSA-601, the second-stage pressure swing adsorption system PSA-602 and the ethane booster K-601 which are connected in sequence.

[0057] Specifically, the ethylbenzene production process includes the following steps:

[0058] 1) The circulating cracking raw material S001 and the fresh cracking raw material S002 are cracked in the cracking furnace F-001 to obtain the cracked gas S101 at the outlet of the cracking furnace, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com