Preparation method of sulfentrazone

A technology of sulfentrazone and methyl sulfonate, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the problem of high pressure safety risk, long reaction time, The problem of low product yield, etc., achieves the effect of less raw material dosage, increased yield and content, and improved reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 4.0g of dimethyl sulfide to 40g of dichloromethane, cool down to -5~0°C, start to pass chlorine gas, and pass in 4.2g of chlorine gas for about 1h, and stir at this temperature for 30min after passing through, as a catalyst Refrigerate and set aside.

Embodiment 2

[0038] Add 4.0g dimethyl sulfide to 40g dichloromethane, cool down to -5~0℃, start to add bromine water (Br 2 The molar ratio of dimethyl sulfide to dimethyl sulfide is 1:1), after passing through, stir at this temperature for 60 minutes, and use it as a catalyst for refrigerated use.

Embodiment 3

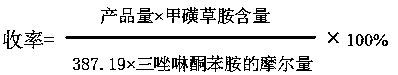

[0040] In a 250ml four-neck flask, dissolve 15.6g (0.05mol) of triazolone aniline in 50g of dichloromethane, lower the temperature to 0-5°C, add the catalyst of Example 1, and make dimethyl sulfonium chloride The mass is 5% of the mass of triazolone aniline, stirred for 30min; then 6.7g of methyl methanesulfonate was added dropwise at this temperature, and after the dripping was completed, the raw materials basically reacted completely at this temperature for 3h; The liquid was cooled to 0°C, suction filtered, and dried to obtain 19.3 g of sulfentrazone as a solid, the content of which was 99.1% as determined by HPLC, and the yield was 98.8%. The filtered mother liquor was distilled, and dichloromethane and methanol were recovered in sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com