One-step in situ preparation method of pa6 mesoporous nanomaterial@ag composite antibacterial resin

A nano-material and in-situ preparation technology, which is applied in the field of preparation of composite antibacterial resins, can solve problems such as complicated process methods, environmental pollution, and low efficiency, and achieve the effects of broad application prospects, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

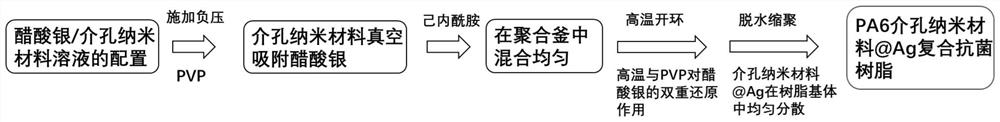

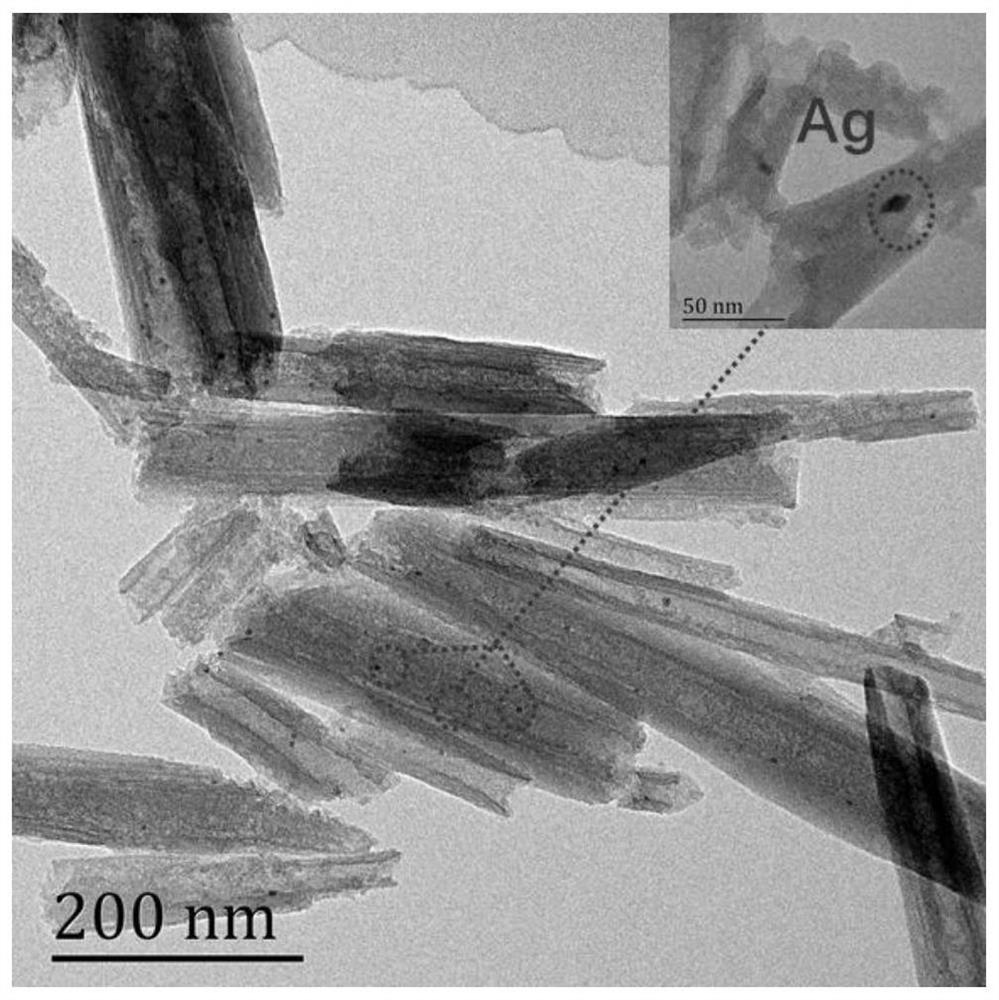

[0021] (1) Dissolve 2g of silver acetate in 60mL of water to form a silver acetate solution, add 35g of mesoporous silica and 0.5g of polyvinylpyrrolidone (PVP) to the solution, form a suspension by ultrasonic stirring, and add it to a 5L polymerization kettle Mesoporous nanomaterials loaded with silver acetate were prepared by applying vacuum negative pressure.

[0022] (2) Add 1.5kg of caprolactam into the above reaction kettle, then raise the temperature to 240°C, and react at this temperature for 2h; after removing water from the whole reaction system, continue to heat up to 260°C, react for 2.5h, and complete the preparation of PA6 mesoporous in one step Silica@Ag composite antibacterial resin.

[0023] According to the antibacterial plastic testing standard QB / T2591-2003A "antibacterial plastic antibacterial performance test method and antibacterial effect", the antibacterial test of the above composite antibacterial resin was carried out, and the antibacterial rate of t...

Embodiment 2

[0025] (1) Dissolve 2.5g of silver acetate in 70mL of water to form a silver acetate solution, add 40g of halloysite nanotubes and 0.6g of polyvinylpyrrolidone (PVP) to the solution, form a suspension by ultrasonic stirring, add it to 5L of polymerization The mesoporous nanomaterials loaded with silver acetate were prepared in the autoclave and applied vacuum negative pressure.

[0026] (2) Add 1.5kg of caprolactam into the above reaction kettle, then raise the temperature to 250°C, and react at this temperature for 2.5h; after removing water from the whole reaction system, continue to heat up to 270°C, react for 2h, and complete the preparation of PA6 Elo in one step Stone nanotube@Ag composite antibacterial resin.

[0027] According to the antibacterial plastic testing standard QB / T2591-2003A "antibacterial plastic antibacterial performance test method and antibacterial effect", the antibacterial test of the above composite antibacterial resin was carried out, and the antiba...

Embodiment 3

[0029] (1) Dissolve 2.5g of silver acetate in 70mL of water to form a silver acetate solution, add 45g of mesoporous titanium dioxide and 0.5g of polyvinylpyrrolidone (PVP) to the solution, form a suspension by ultrasonic stirring, and add it to a 5L polymerization kettle And applying vacuum negative pressure to prepare mesoporous nanomaterials loaded with silver acetate.

[0030] (2) Add 1.5kg of caprolactam into the above reaction kettle, then raise the temperature to 250°C, and react at this temperature for 2 hours; after removing water from the entire reaction system, continue to heat up to 270°C, react for 4 hours, and complete the preparation of PA6 mesoporous titanium dioxide in one step @Ag composite antibacterial resin.

[0031] According to the antibacterial plastic testing standard QB / T2591-2003A "antibacterial plastic antibacterial performance test method and antibacterial effect", the antibacterial test of the above composite antibacterial resin was carried out, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com