Preparation method of modified nanometer resin based wood lacquer

A resin-based, wood paint technology, applied in the direction of epoxy resin coatings, biocide-containing paints, coatings, etc., can solve the problems of not meeting the market requirements of coatings, uneven distribution of coating films, poor antibacterial properties, etc., and achieve strength improvement , improve the uniformity of distribution, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

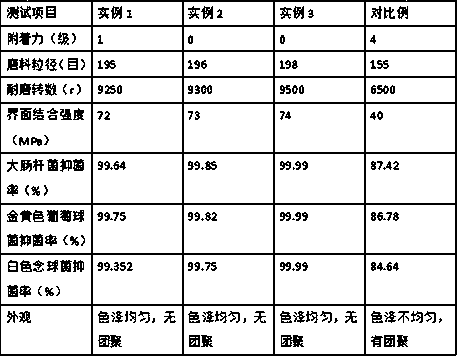

example 1

[0023]According to the mass ratio of 3:1, mix and stir the silica sol with a mass fraction of 18% and deionized water for 10 minutes to obtain a dispersion, and then add a silver nitrate solution with a concentration of 7% of the volume of the dispersion and a concentration of 0.5mol / L to the dispersion. , and mixed and stirred for 16 minutes to obtain an oxidation solution; according to the mass ratio of 1:5, anhydrous glucose and deionized water were mixed and placed in a beaker, and stirred and dissolved for 6 minutes to obtain a glucose solution, and then the glucose solution was added to the glucose solution. % absolute ethanol and 1% polyethylene glycol of glucose solution mass, continue to mix and stir to dissolve for 21min, and obtain the self-made glucose reduction solution; under constant temperature magnetic stirring, drop the self-made glucose reduction solution to the In the oxidation solution, stir and react at a temperature of 65°C for 1 hour, cool and discharge ...

example 2

[0025] According to the mass ratio of 3:1, mix and stir the silica sol with a mass fraction of 18% and deionized water for 11 minutes to obtain a dispersion, and then add a silver nitrate solution with a concentration of 7% of the volume of the dispersion and a concentration of 0.5mol / L to the dispersion. , and mixed and stirred for 18 minutes to obtain an oxidation solution; according to the mass ratio of 1:5, anhydrous glucose and deionized water were mixed and placed in a beaker, and stirred and dissolved for 7 minutes to obtain a glucose solution, and then the glucose solution was added to the glucose solution. % absolute ethanol and 1% polyethylene glycol of glucose solution quality, continue to mix and stir to dissolve 23min, obtain self-made glucose reducing solution; In the oxidation solution, stir and react at a temperature of 67°C for 1.5 hours, cool and discharge the material to obtain a self-made silver-loaded silica sol; mix and stir bisphenol A epoxy resin and acr...

example 3

[0027] According to the mass ratio of 3:1, mix and stir the silica sol with a mass fraction of 18% and deionized water for 12 minutes to obtain a dispersion, and then add a silver nitrate solution with a concentration of 7% of the volume of the dispersion and a concentration of 0.5mol / L to the dispersion. , and mixed and stirred for 20 minutes to obtain an oxidation solution; according to the mass ratio of 1:5, anhydrous glucose and deionized water were mixed and placed in a beaker, and stirred and dissolved for 8 minutes to obtain a glucose solution, and then the glucose solution was added to the glucose solution. % absolute ethanol and 1% polyethylene glycol in glucose solution quality, continue to mix and stir to dissolve for 24min to obtain self-made glucose reducing solution; under constant temperature magnetic stirring, add the self-made glucose reducing solution dropwise to In the oxidizing solution, stir and react at a temperature of 70°C for 1 to 2 hours, cool and disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com