Environment-friendly superhydrophobic anti-impact epoxy resin powder coating and preparation method thereof

A technology of epoxy resin powder and phenolic epoxy resin, which is applied in the field of environmental protection super-hydrophobic and impact-resistant epoxy resin powder coating and its preparation, can solve the problems of poor waterproof effect, brittle epoxy resin, etc., and achieves increased heat resistance. properties, prolonging service life, and improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

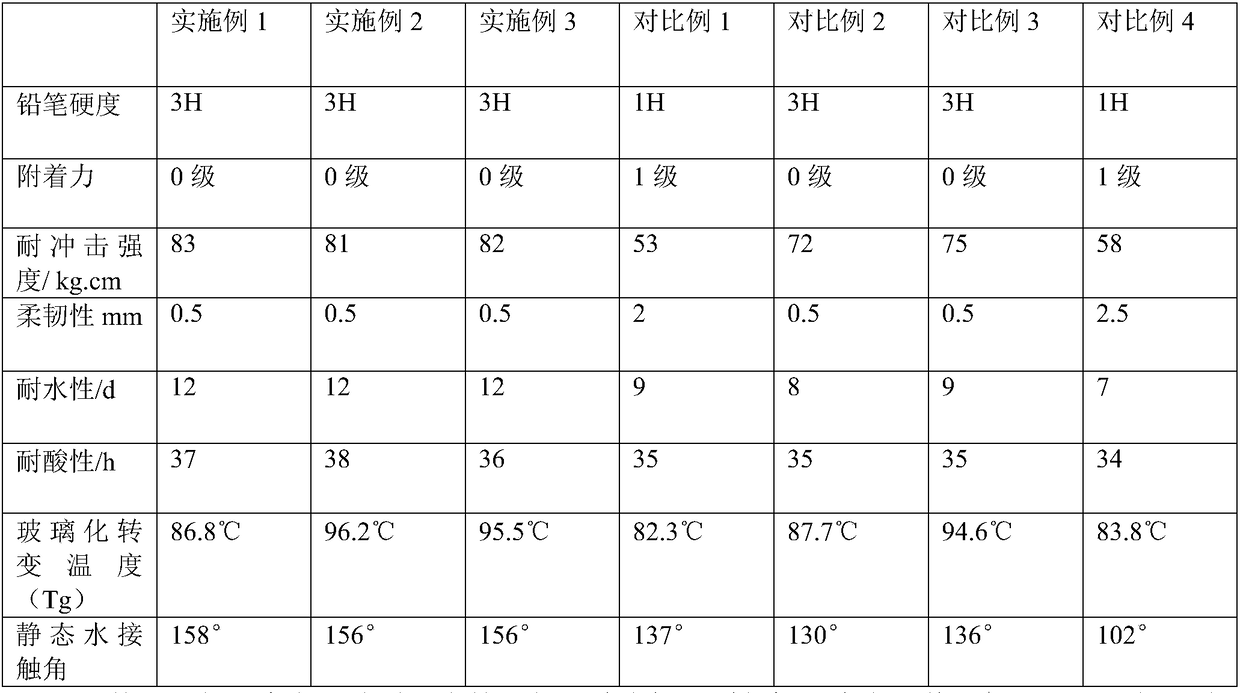

Embodiment 1

[0020] An environment-friendly superhydrophobic impact-resistant epoxy resin powder coating, comprising the following raw materials in parts by weight:

[0021] 70 parts of modified novolak epoxy resin, 20 parts of nanoclay, 15 parts of carbon black, 10 parts of aluminum nitride micro-particles, 0.2 parts of zinc oxide, 0.2 parts of sodium pentachlorophenate, 0.5 parts of 2,4-dihydroxybenzophenone 1 part, 1 part of borax, 0.2 part of p-phenylenediamine.

[0022] The preparation method of modified novolac epoxy resin is:

[0023] Add 5 parts by weight of novolac epoxy resin and 150 parts by weight of n-butanol into a four-necked flask, heat up to 70°C, stir and dissolve, then add 3 parts by weight of crotonic acid, 2 parts by weight of Leaf alcohol, 2 parts by weight of γ-methacryloxypropyl trimethoxysilane and 0.02 parts by weight of dimethyl azobisisobutyrate initiator, stirred for 4 hours, and the normal The butanol solvent is distilled off, and the modified novolac epoxy ...

Embodiment 2

[0030] An environment-friendly superhydrophobic impact-resistant epoxy resin powder coating, comprising the following raw materials in parts by weight:

[0031] 70 parts of modified novolak epoxy resin, 20 parts of nanoclay, 15 parts of carbon black, 10 parts of aluminum nitride micro-particles, 0.2 parts of zinc oxide, 0.2 parts of sodium pentachlorophenate, 0.5 parts of 2,4-dihydroxybenzophenone 1 part, 1 part of borax, 0.2 part of p-phenylenediamine, Fe 2 o 3 -Ca 2 NbO 7 - 3 parts of MgO powder.

[0032] The preparation method of modified novolac epoxy resin is:

[0033] Add 5 parts by weight of novolac epoxy resin and 150 parts by weight of n-butanol into a four-necked flask, heat up to 70°C, stir and dissolve, then add 3 parts by weight of crotonic acid, 2 parts by weight of Leaf alcohol, 2 parts by weight of γ-methacryloxypropyl trimethoxysilane and 0.02 parts by weight of dimethyl azobisisobutyrate initiator, stirred for 4 hours, and the normal The butanol solvent...

Embodiment 3

[0042] An environment-friendly superhydrophobic impact-resistant epoxy resin powder coating, comprising the following raw materials in parts by weight:

[0043] 73 parts of modified novolac epoxy resin, 25 parts of nano clay, 16 parts of carbon black, 13 parts of aluminum nitride micro-particles, 0.3 parts of zinc oxide, 0.3 parts of sodium pentachlorophenate, 0.6 parts of 2,4-dihydroxybenzophenone Parts, 1.2 parts of borax, 0.3 parts of p-phenylenediamine, Fe 2 o 3 -Ca 2 NbO 7 - 3.5 parts of MgO powder.

[0044] The preparation method of modified novolac epoxy resin is:

[0045] Add 6 parts by weight of novolac epoxy resin and 160 parts by weight of n-butanol into a four-necked flask, heat up to 73°C, stir and dissolve, then add 4 parts by weight of crotonic acid, 3 parts by weight of Leaf alcohol, 3 parts by weight of γ-methacryloxypropyltrimethoxysilane and 0.02 parts by weight of dimethyl azobisisobutyrate initiator, stirring for 4.5h, using a rotary evaporator to Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com