Preparation method of karst foam nickel for electrocatalytic full decomposition of water for hydrogen production and oxygen production

A nickel foam, full decomposition technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of poor hydrogen production and oxygen production activity, achieve excellent electrocatalytic activity and stability, improve mass transfer and charge transfer Efficiency, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

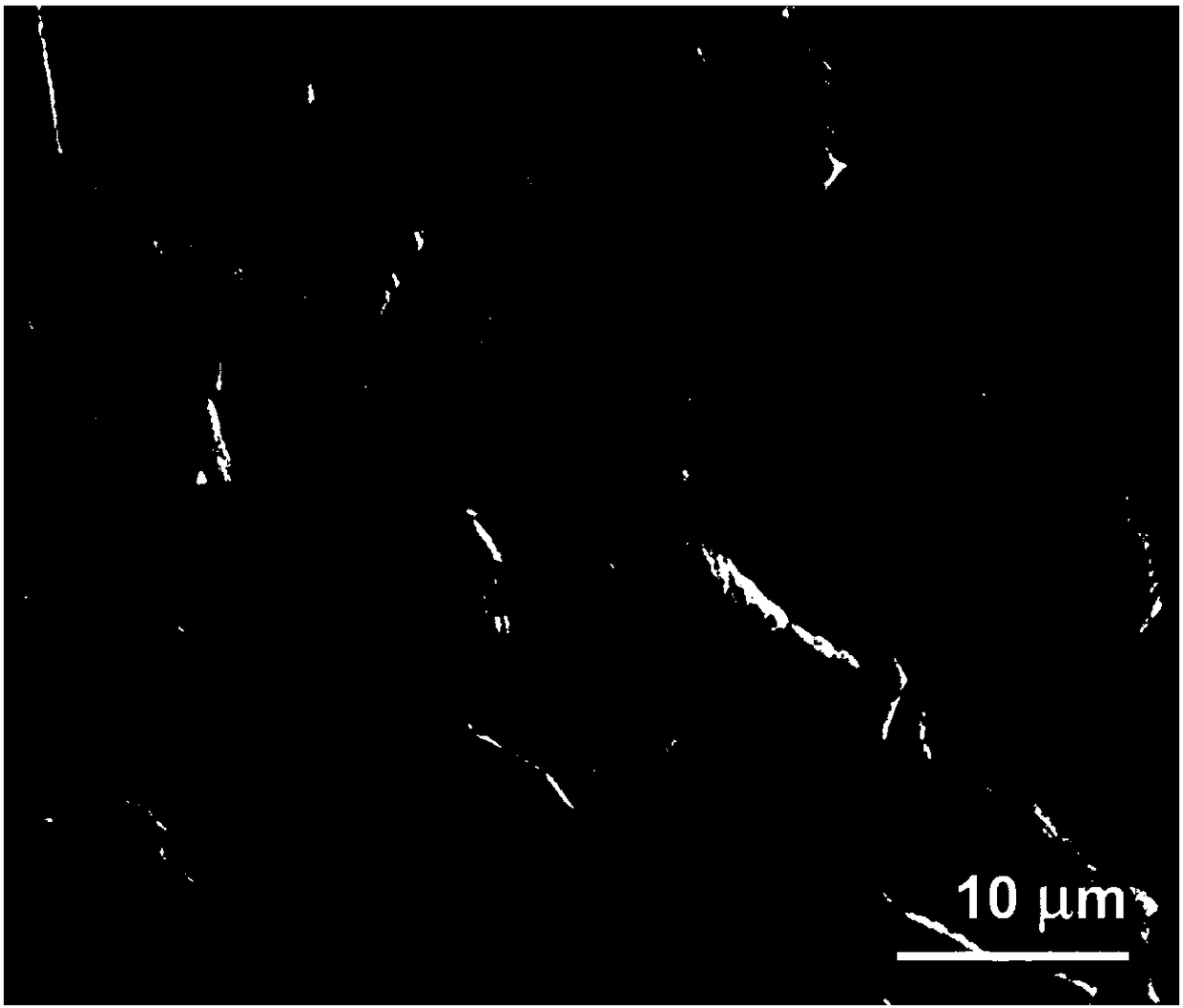

Embodiment 1

[0028] 1. Pretreatment

[0029] 0.5cm×0.5cm nickel foam (thickness 1.7mm, surface density 380±20g m -2 , the number of pores is 110PPI) in 2mol / L HCl aqueous solution, water and ethanol in order to ultrasonically treat each for 30 minutes to remove oxides and pollutants on the surface of nickel foam, so that the nickel foam exposes a clean Ni metal surface.

[0030] 2. Etching of nickel foam

[0031] Under normal temperature conditions, the foamed nickel pretreated in step 1 was used as the working electrode, the graphite rod was used as the counter electrode, and the saturated Ag / AgCl was used as the reference electrode. 2 SO 4 Applying 0.1V (vs Ag / AgCl) constant voltage electrolysis in aqueous solution for 300s, foamed nickel is in electrochemical etching and H 2 SO 4 Under the combined action of etching, the surface is Ni and α-Ni(OH) 2 Heterojunction active ingredient, the interior is the nano tower peak of metallic Ni; Wash the foamed nickel with deionized water and ...

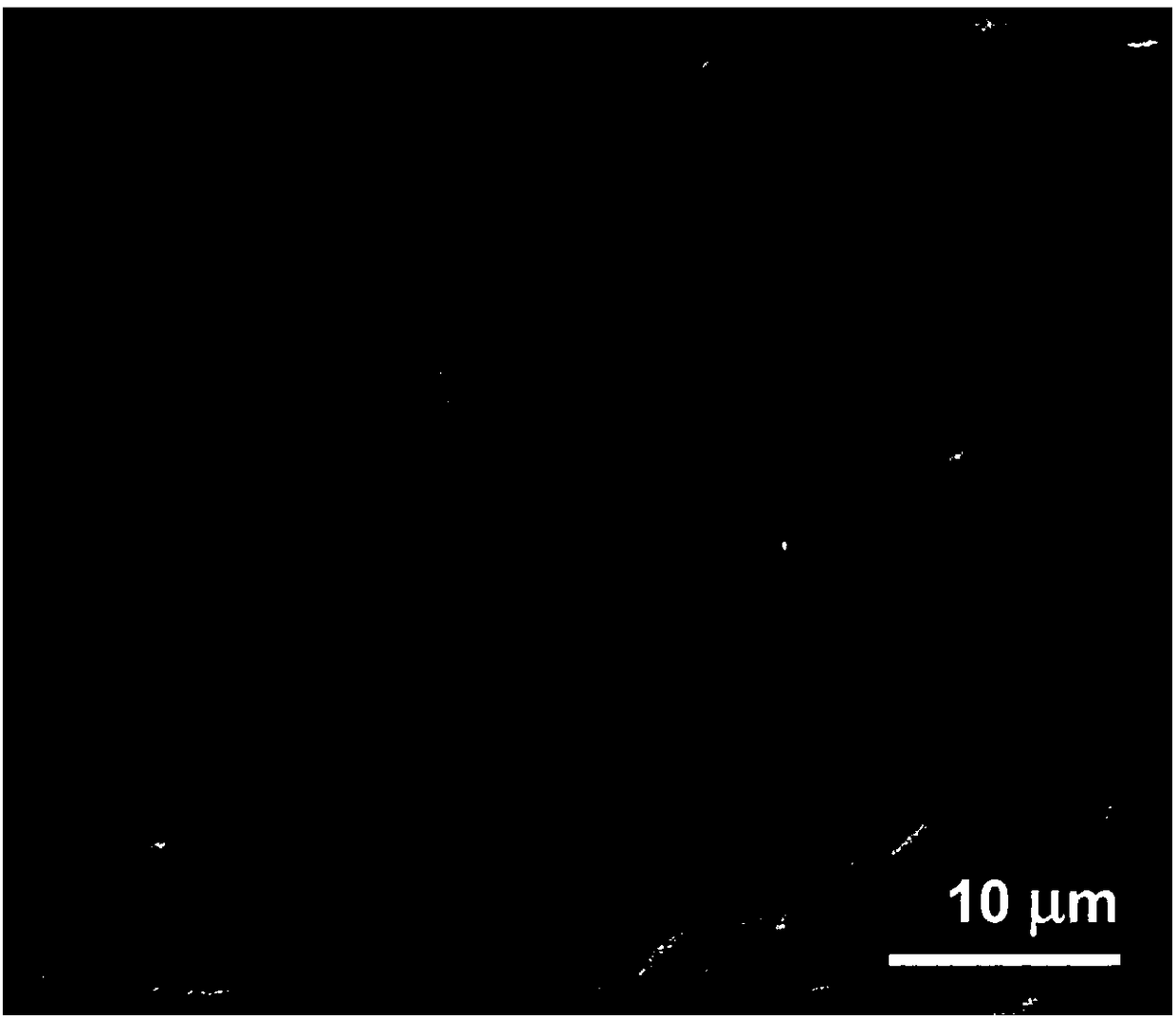

Embodiment 2

[0033] In this embodiment, at 0.5mol / L H 2 SO 4 Apply 0.1V (vs Ag / AgCl) constant voltage electrolysis 200s in the aqueous solution, other steps are identical with embodiment 1, obtain karst foamed nickel (see figure 2 ).

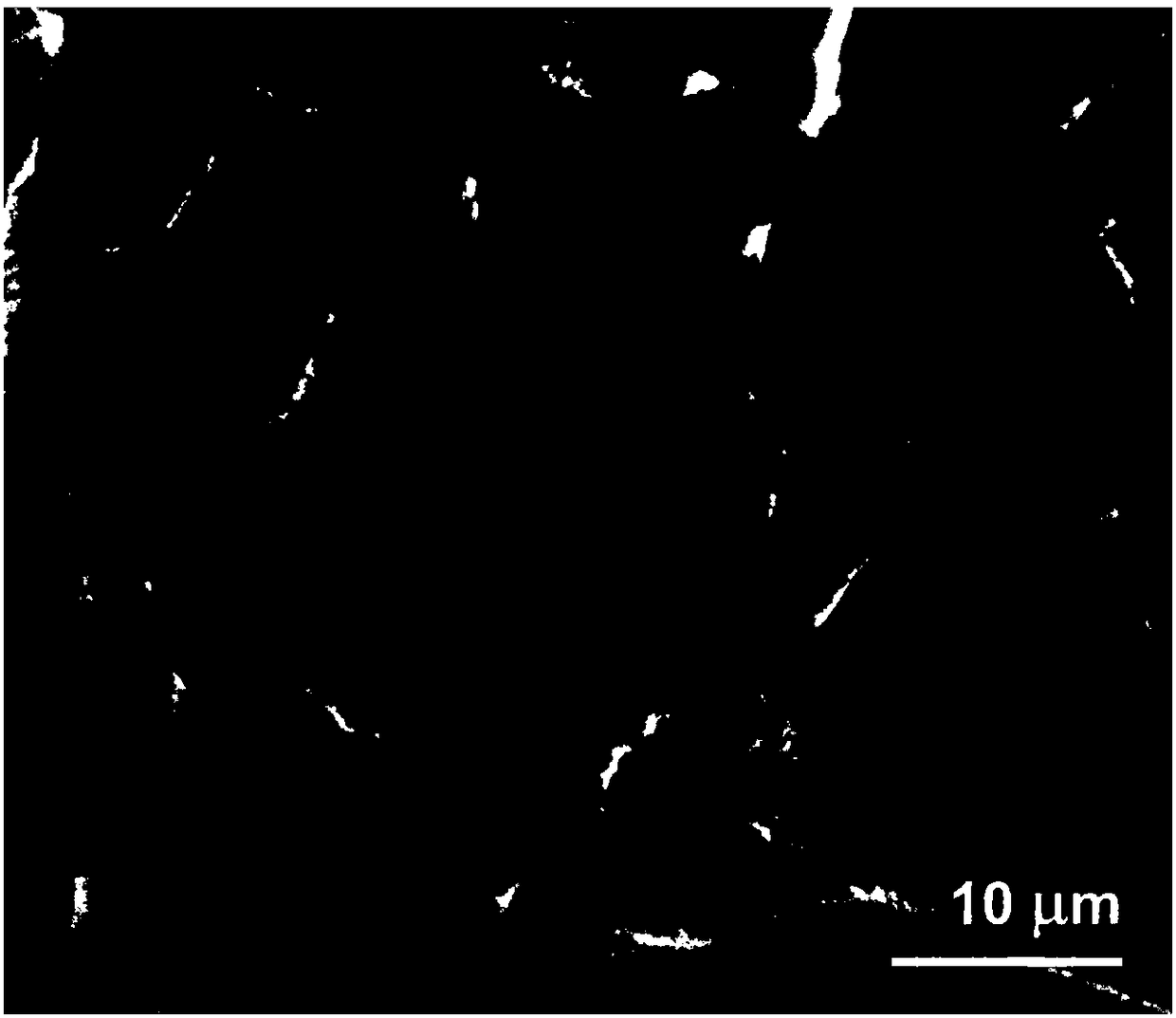

Embodiment 3

[0035] In this embodiment, at 0.25mol / L H 2 SO 4 Apply 0.1V (vs Ag / AgCl) constant voltage electrolysis 600s in the aqueous solution, other steps are identical with embodiment 1, obtain karst foamed nickel (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com