Integrated gas-type pearlite expansion apparatus based on spiral tube heat exchange

A gas-fired, perlite technology, applied to lighting and heating equipment, gas fuel burners, burners, etc., can solve problems such as insufficient, affecting production efficiency, low combustion rate of natural gas fuel, etc., to increase surface area and improve transmission effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

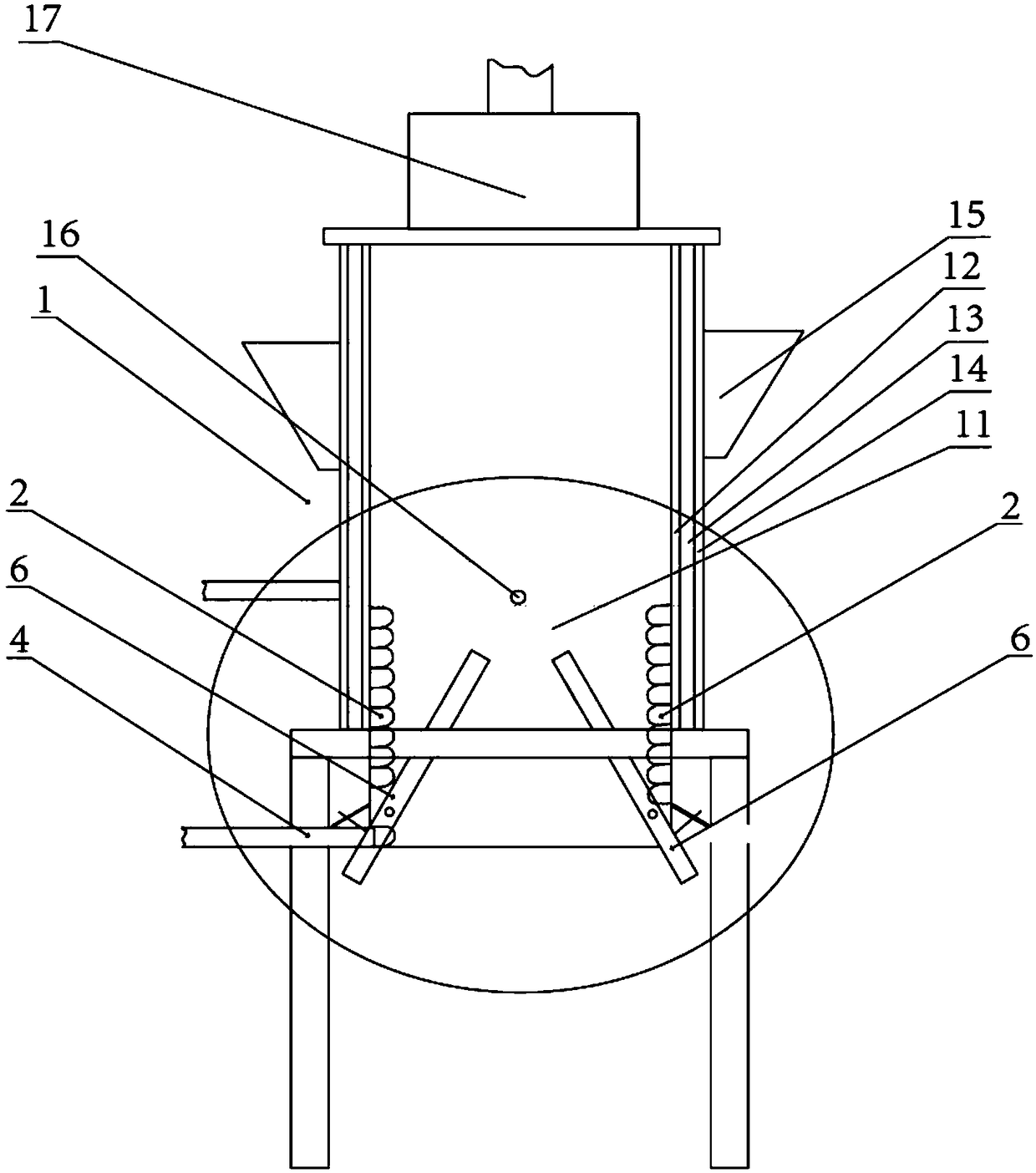

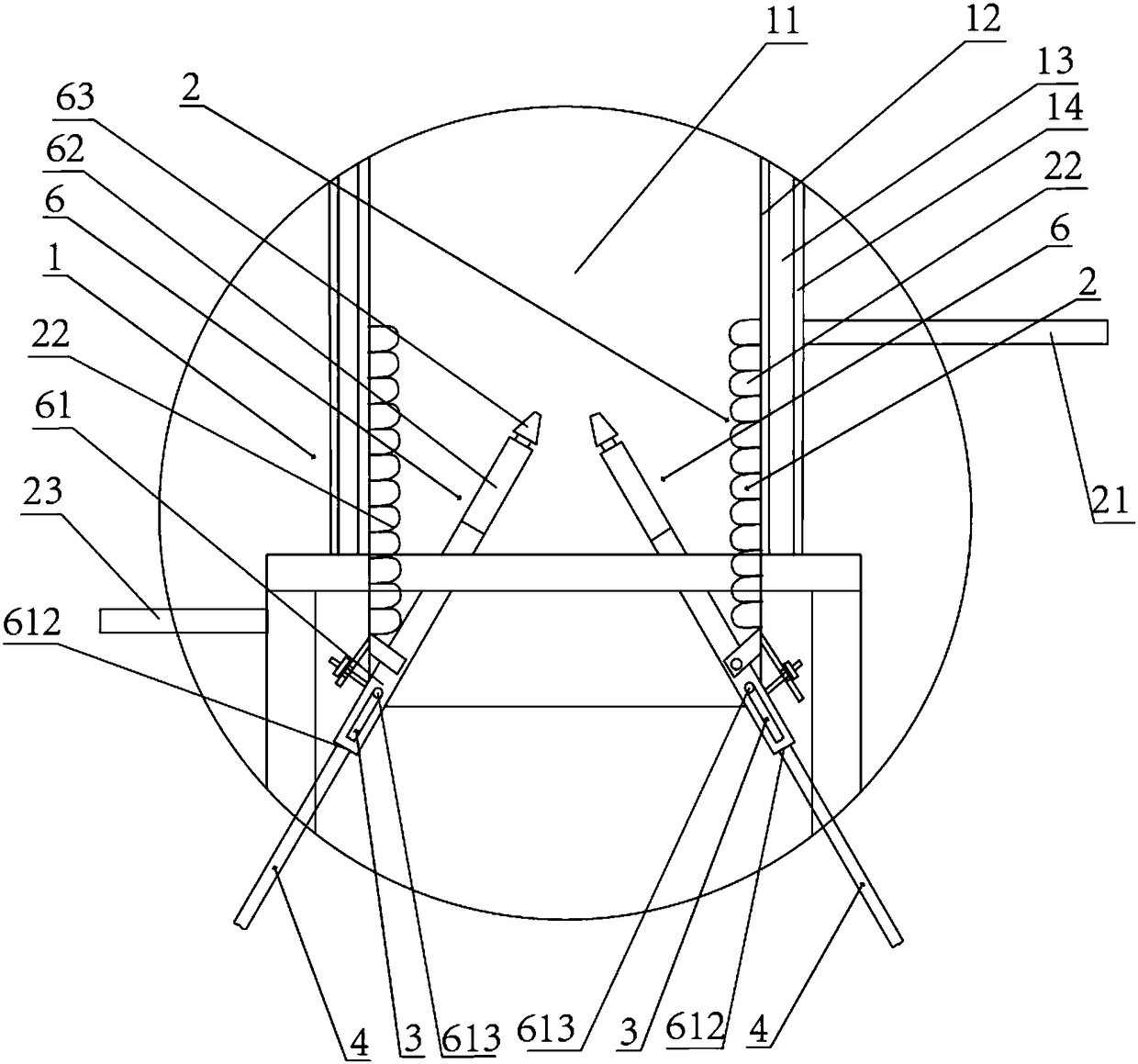

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

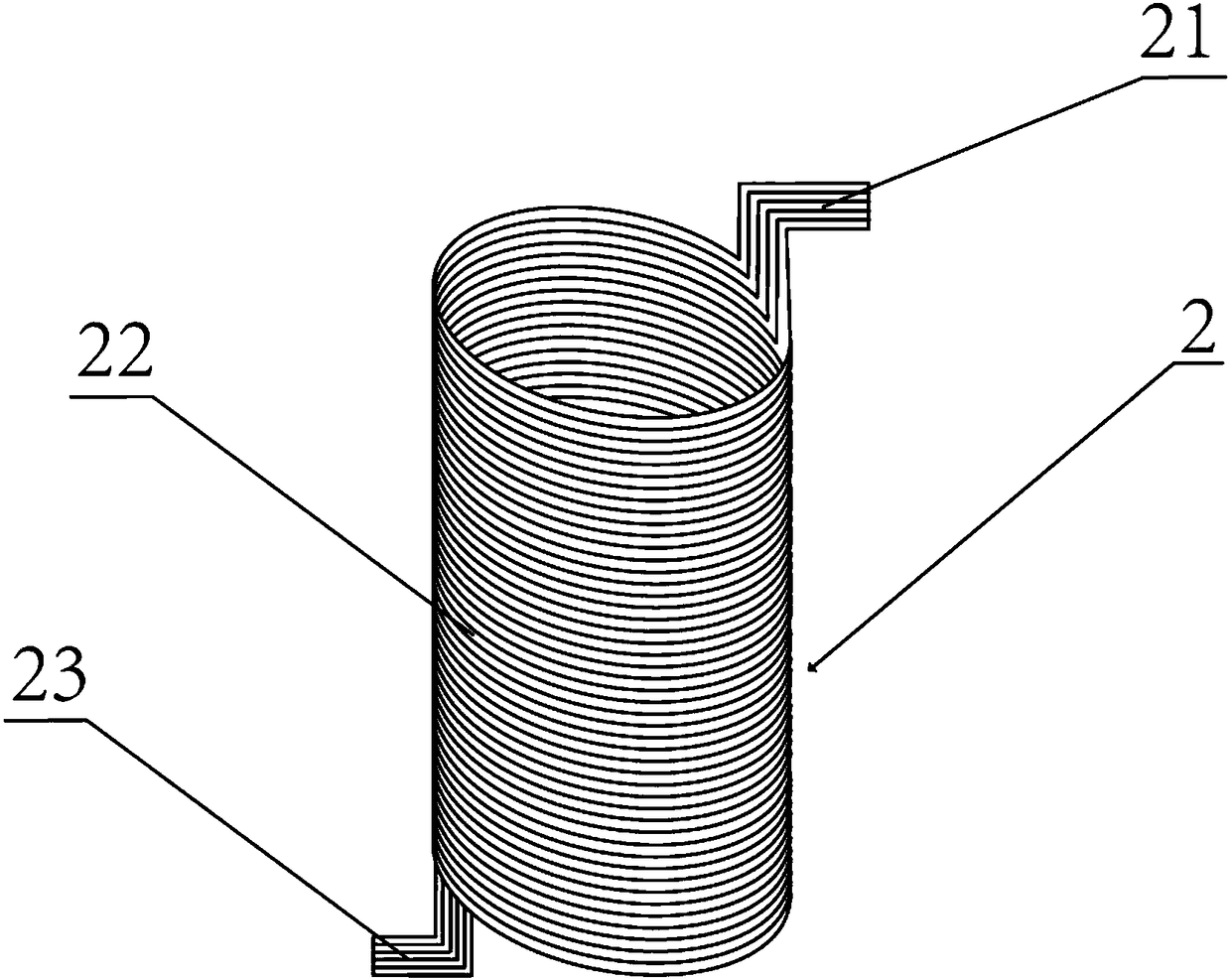

[0022] like Figure 1 to Figure 6 As shown, the integrated gas-fired perlite expansion equipment based on spiral tube heat exchange of the present invention includes an expansion furnace body 1, a spiral heat exchange pipeline 2, a natural gas transmission pipeline 3, an air transmission pipeline 4, a blower 5 and a gas combustion device 6, where:

[0023] The expansion furnace body 1 is arranged on the expansion furnace frame. The expansion furnace body 1 includes a furnace 11, a furnace brick wall 12, a heat insulation layer 13 and an outer shell 14. The furnace 11 is designed as a Venturi with a wider upper part and a narrower lower part. In the tubular structure, the perlite material is heated and expanded in the furnace 11 by the high-temperature flame ejected from the gas burner 6 arrange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap