High-safety non-woven-fabric-based composite separation film and preparation method thereof

A non-woven-based, composite diaphragm technology, applied in structural parts, electrical components, battery pack parts, etc., can solve the problems of poor heat resistance of the diaphragm, unfavorable use of the diaphragm, etc. Effects of insulation, good ion transport and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

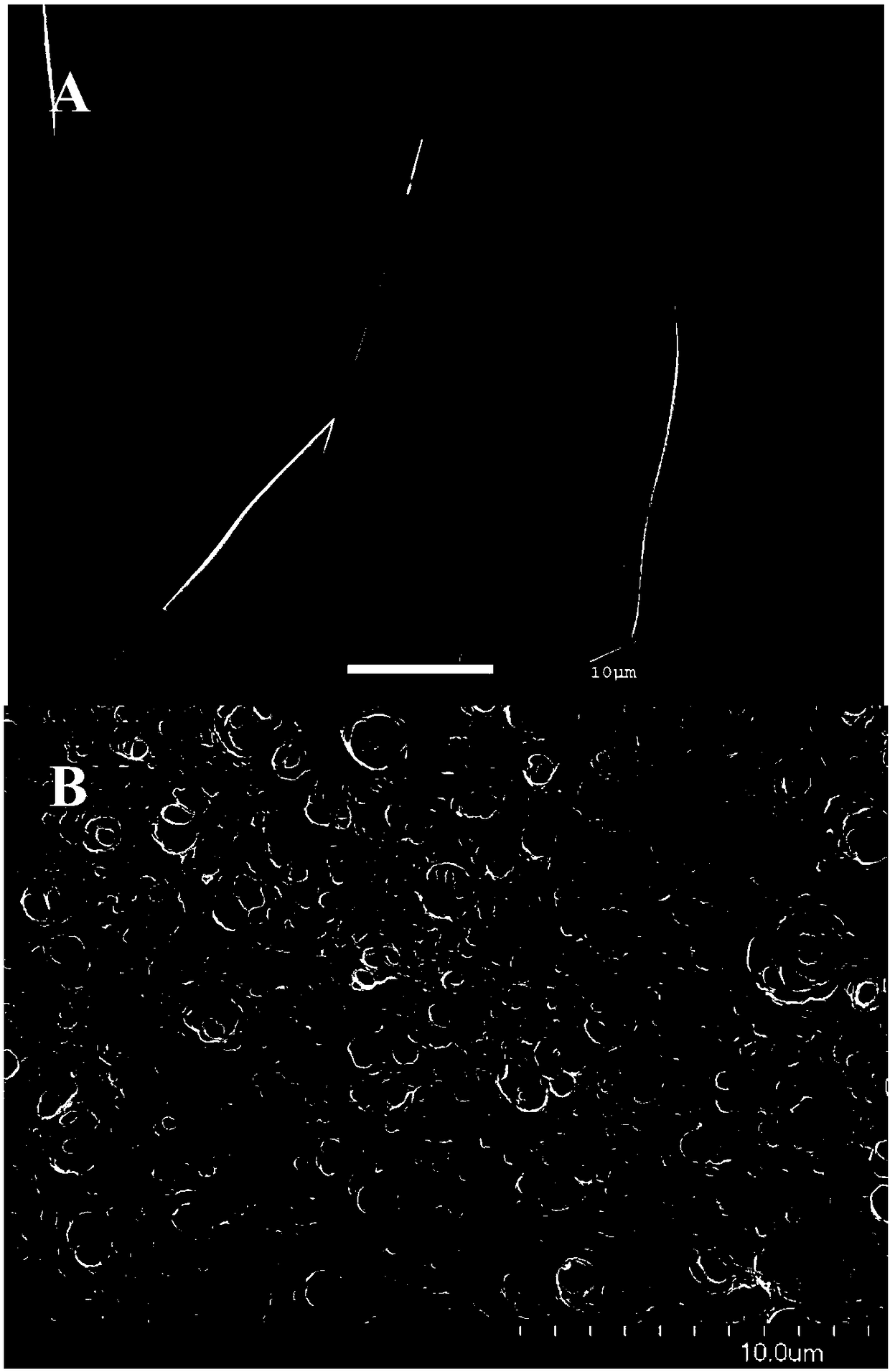

[0036] A method for preparing a high-safety non-woven fabric-based composite diaphragm, the specific steps are as follows:

[0037] (1) Take 5g of polyetherimide particles, slowly add it to 95g of dimethylformamide reagent at a temperature of 120°C, stir until the polyetherimide particles are completely dissolved, and then cool the solution to 80°C , adding 3 drops of ethylene glycol monobutyl ether therein, stirring evenly to obtain a coating solution;

[0038] (2) Completely immerse the PET substrate with a thickness of 15 μm and a porosity of 70% in the mixed solution for 2 minutes, take out the PET composite membrane, remove the residual solution on the surface of the PET composite membrane with a scraper with a distance of 20 μm, and then air-dry it naturally for 30 minutes , and then vacuum-dried at 120°C for 12 hours to obtain a high-safety non-woven fabric-based composite separator.

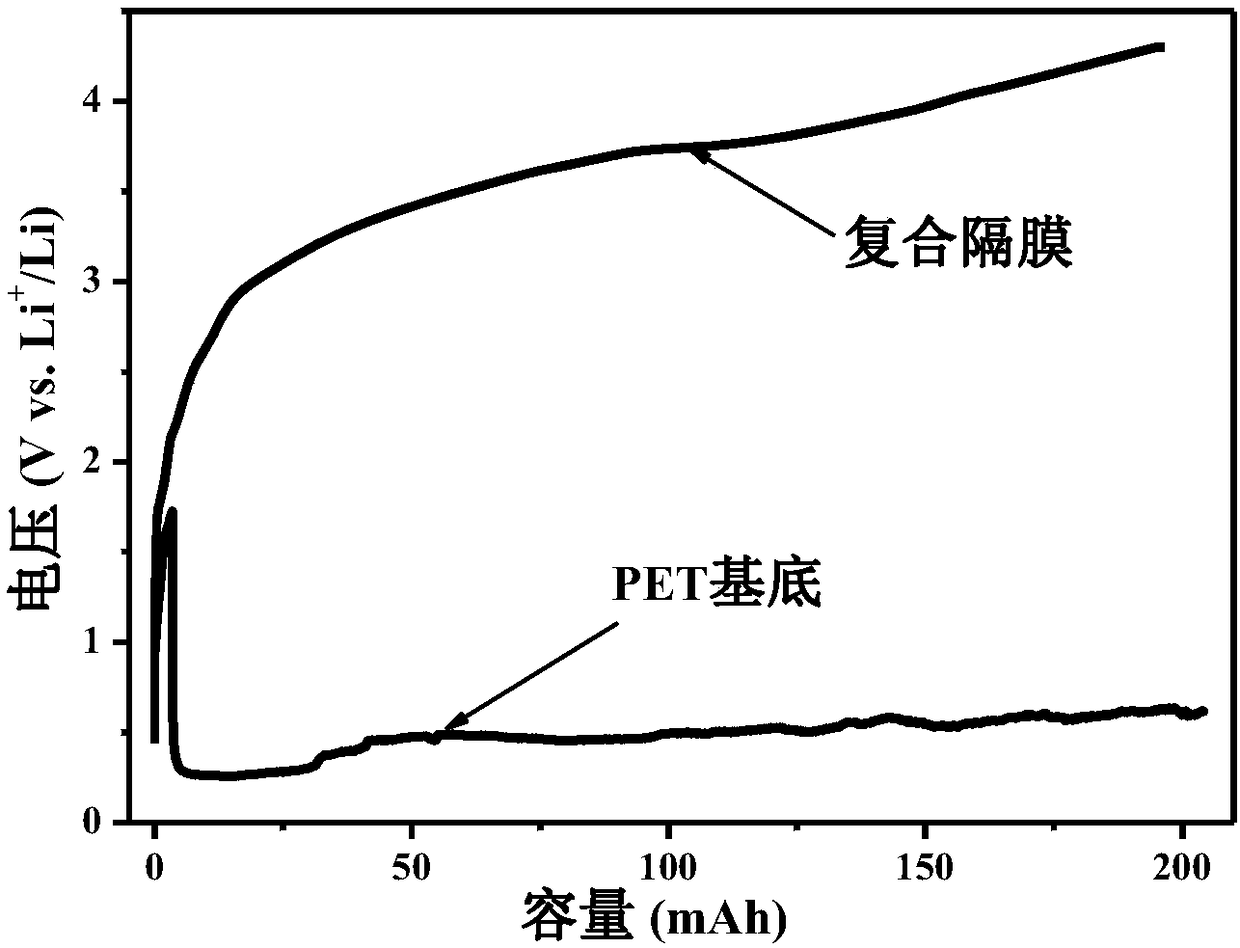

[0039] The performance of the high-safety non-woven fabric-based composite diaphragm...

Embodiment 2

[0043] A method for preparing a high-safety non-woven fabric-based composite diaphragm, the specific steps are as follows:

[0044] (1) Take 10g of polyamic acid, slowly add it to the dimethylacetamide reagent with a mass of 90g and a temperature of 100°C, stir until a uniform solution is formed, cool the solution to 50°C, and add 3 drops of polyethylene glycol to it. Glycol, stir evenly, obtain coating solution;

[0045] (2) Submerge the polyacrylonitrile substrate with a thickness of 12 μm and a porosity of 60% in the mixed solution for 2 minutes, take out the polyacrylonitrile composite diaphragm, and remove the residual solution on the surface of the polyacrylonitrile composite diaphragm with a spatula with a distance of 15 μm , naturally air-dried in the air for 30 minutes, and then vacuum-dried at 120°C for 12 hours to obtain a high-safety non-woven fabric-based composite separator.

Embodiment 3

[0047] A method for preparing a high-safety non-woven fabric-based composite diaphragm, the specific steps are as follows:

[0048] (1) Take 10g of polyetherimide particles, slowly add it to N-methylpyrrolidone reagent with a mass of 90g and a temperature of 100°C, stir until the polyetherimide particles are completely dissolved, and then cool the solution to 80°C , adding 3 drops of ethylene glycol monobutyl ether therein, stirring evenly to obtain a coating solution;

[0049] (2) Completely immerse the PET substrate with a thickness of 12 μm and a porosity of 80% in the mixed solution for 2 minutes, take out the PET composite membrane, remove the residual solution on the surface of the PET composite membrane with a scraper with a distance of 15 μm, and then air dry it naturally for 30 minutes , and then vacuum-dried at 100°C for 24 hours to obtain a high-safety non-woven fabric-based composite separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com