Preparation device and method for ternary material precursor

A technology of ternary materials and precursors, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., to achieve the effects of good sphericity, strong process controllability, and spheroidized particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

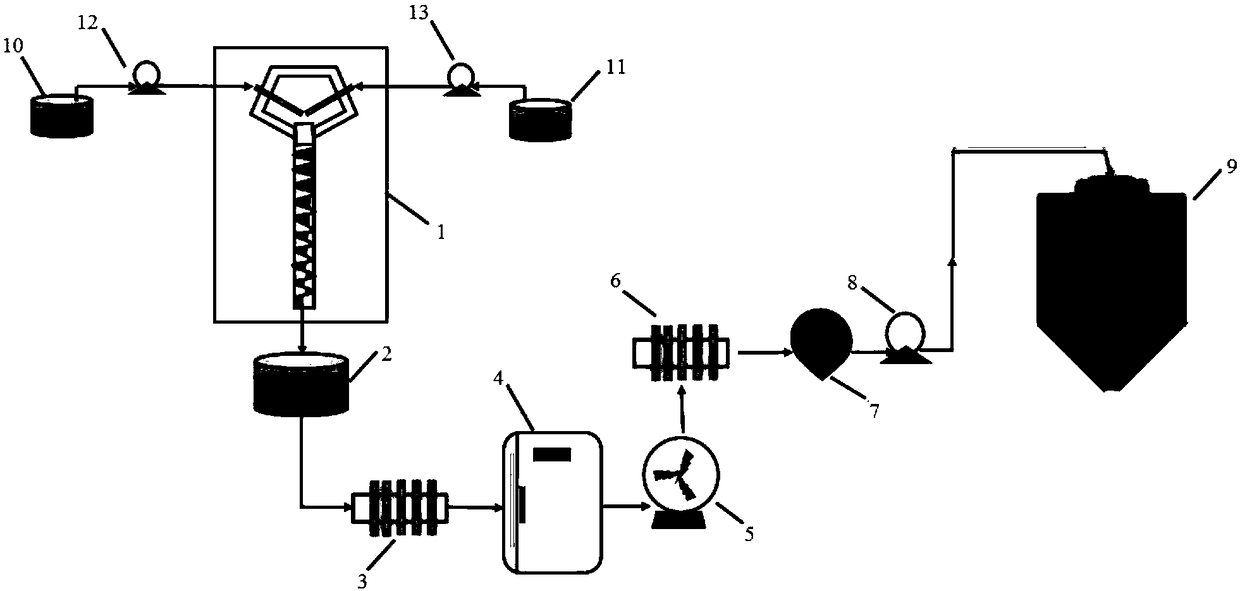

[0035] Such as figure 1 As shown, this embodiment provides a preparation equipment for a ternary material precursor, including a jet tube reactor 1, an ultrasonic aging tank 2, a first tympanic plate-and-frame filter press 3, and a pre-drying equipment connected sequentially through pipelines 4. Wet stirring ball mill 5, second tympanic plate and frame filter press 6, beater 7, material delivery pump 8 and spray drying tower 9, jet tube reactor 1 is connected with mixed salt solution storage tank 10 and coprecipitation Agent storage tank 11.

[0036] Wherein, a first constant flow pump 12 is provided between the jet tube reactor 1 and the mixed salt solution storage tank 10 , and a second constant flow pump 13 is provided between the jet tube reactor 1 and the coprecipitant storage tank 11 .

[0037] The jet tube reactor 1 is provided with a helical channel 14 , and the materials are impacted and mixed in the jet tube reactor 1 , and undergo time-delay reaction in the helical...

Embodiment 2

[0049] Different from Example 1 is the preparation method of the ternary material, the method at least includes the following steps:

[0050] In the first step, nickel nitrate, cobalt acetate, and manganese oxalate are added to the mixed solvent of ethanol and water (the volume ratio of the two is 1:1) according to the molar ratio of 8:1:1 and mixed evenly to obtain a mixed solution of 3mol / L. Salt solution, add the mixed salt solution into the mixed salt solution storage tank 10; mix 3mol / L NaOH and 3mol / L ammonia water in a volume ratio of 2:1 to obtain coprecipitant solution, add coprecipitant storage tank 11 middle;

[0051] In the second step, the solution in the mixed salt solution storage tank 10 and the co-precipitant storage tank 11 is heated to 52 ° C, and through the precise metering of the first constant flow pump 12 and the second constant flow pump 13, a constant feed ratio is supplied to the Feeding in the jet tube reactor 1, so that the pH value of the mixed s...

Embodiment 3

[0057] Different from Example 1 is the preparation method of the ternary material, the method at least includes the following steps:

[0058] In the first step, nickel acetate, cobalt nitrate, and aluminum nitrate are added to a mixed solvent of acetone and water (the volume ratio of the two is 1:1) according to the molar ratio of 7:2:1 and mixed evenly to obtain 2.5mol / L Mix the salt solution, add the mixed salt solution into the mixed salt solution storage tank 10; mix 2.5mol / L NaOH and 2.5mol / L ammonia water at a volume ratio of 2:1 to obtain a coprecipitant solution, add the coprecipitant In storage tank 11;

[0059] In the second step, the solution in the mixed salt solution storage tank 10 and the co-precipitant storage tank 11 is heated to 58 ° C, and the precise metering of the first constant flow pump 12 and the second constant flow pump 13 is carried out with a constant feed ratio. Feeding in the jet tube reactor 1, so that the pH value of the mixed slurry is 11;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com