Lattice defect-control orthogonal-emission rare earth upconversion nanoparticle and preparation method

A technology of rare earth up-conversion and nano-particles, which is applied in the field of nano-materials and achieves the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

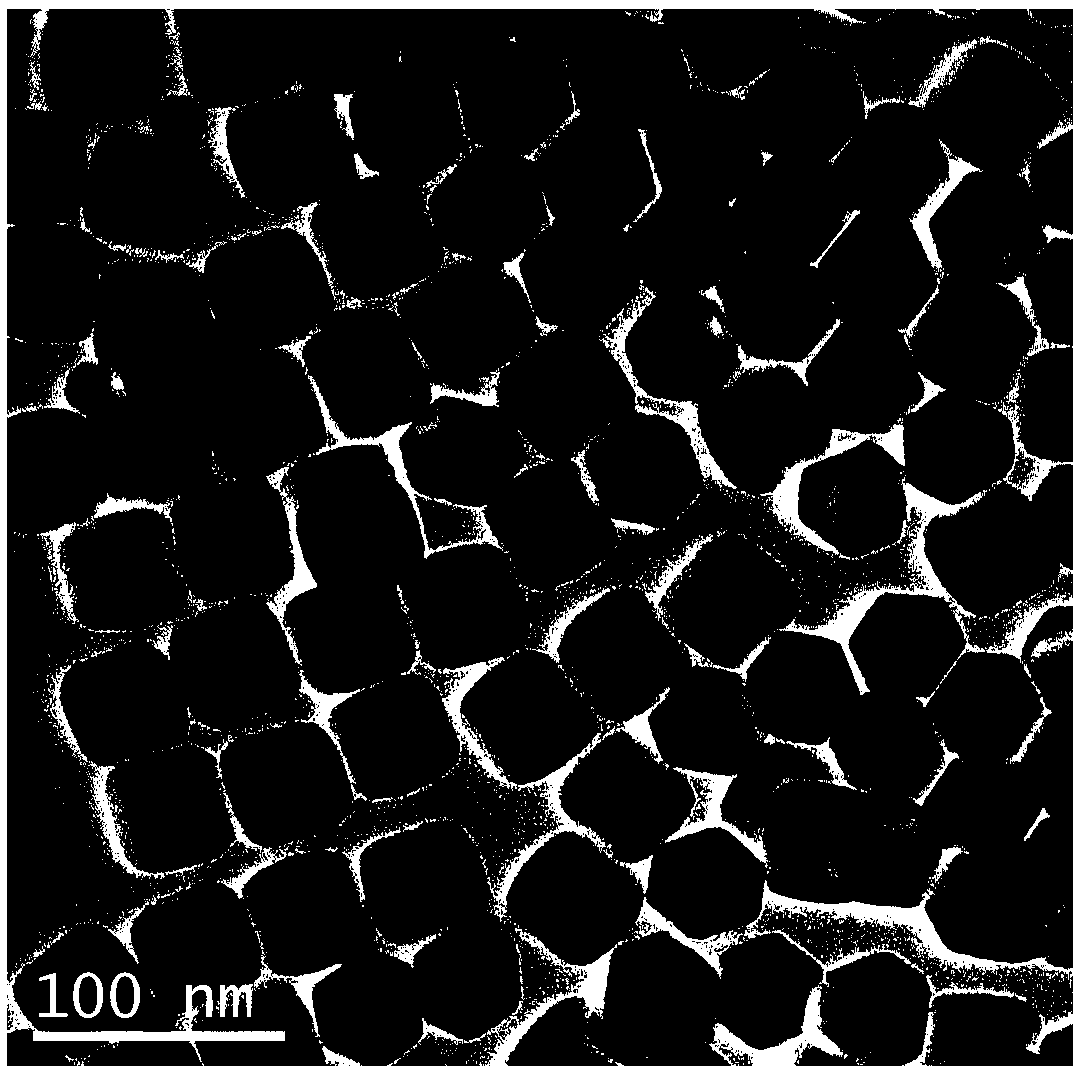

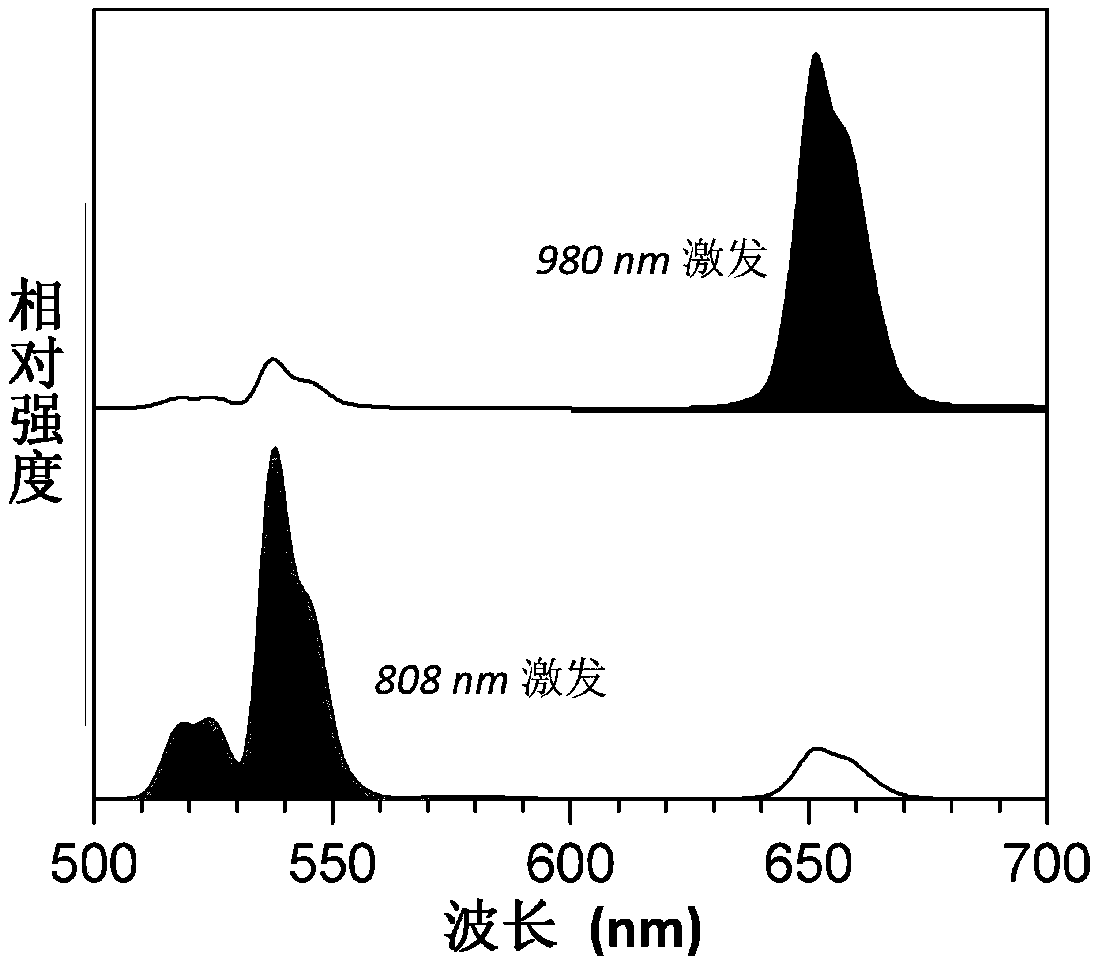

[0040] In this embodiment, the core layer particles are prepared by the hydrothermal method, and then the inner shell layer and the outer shell layer are wrapped on the core layer by the high-temperature pyrolysis method. The specific steps are:

[0041] 1) Stir and mix erbium acetate, yttrium acetate, ytterbium acetate and manganese acetate with sodium fluoride, oleic acid, sodium hydroxide and ethanol according to the ratio of 0.02mmol: 0.4mmol: 0.18mmol: 0.4mmol, and add it to the reaction kettle to heat up to 150-200°C, keep warm for 8-10 hours, cool to room temperature after the reaction, add ethanol and centrifuge, add the obtained particles into a mixed solution of oleic acid (5-10ml) and octadecene (10-20ml), and heat up to 250 -300°C, react for 1 hour, then cool to room temperature, add ethanol and centrifuge to wash to obtain core layer nanoparticles.

[0042] 2) Mix yttrium acetate and ytterbium acetate according to the molar percentage of 0.9mmol: 0.1mmol, mix with...

Embodiment 2

[0046] In this example, the above-mentioned rare earth up-conversion nanoparticles were prepared by a high-temperature pyrolysis coating method, and the specific steps were as follows:

[0047] 1) Mix erbium acetate, thulium acetate and ytterbium acetate in molar percentages of 0.495mmol: 0.005mmol: 0.5mmol, mix with 5-10mL oleic acid, 10-20mL octadecene, and heat up to 110°C under magnetic stirring , and then vacuum to remove water and oxygen. N 2 , heat up to 100-150°C, keep warm for 30 minutes; then cool to room temperature, will contain NaOH and NH 4 Add the methanol solution of F into a three-necked flask, heat up to 110°C, and vacuum to remove methanol and oxygen; 2 Protect, raise the temperature to 250-300°C, and react for 0.5-1h; after the reaction, cool to room temperature, add appropriate ethanol and centrifuge to wash to obtain Tm-doped core layer nanoparticles.

[0048] 2) Add yttrium acetate and ytterbium acetate to 0.9mmol:0.1mmol according to the molar percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com