Preparation method of spongy tantalum sheets

A technology of spongy and tantalum flakes, applied in the field of preparation of spongy tantalum flakes, can solve the problems of narrow processing efficiency of processing heat affected zone, high surface friction coefficient, high volume porosity, etc., achieving easy decomposition and high porosity. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

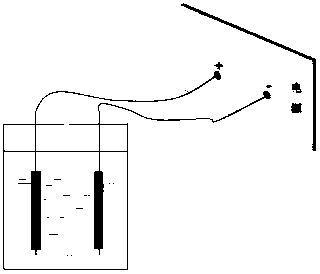

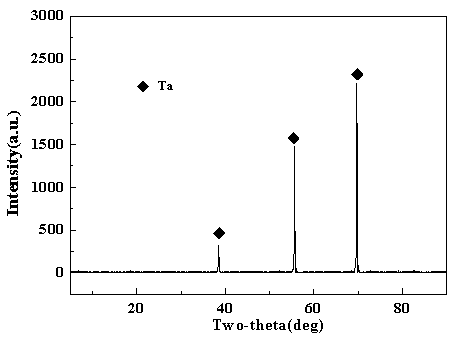

Embodiment 1

[0032] It is 0.1mol / L tetraethylammonium chloride and 95% ethanol to prepare 500ml electrolyte solution with a concentration of 0.1mol / L, and prepare as figure 1 The device for preparing the sponge-like tantalum sheet includes an adjustable DC power supply and an electrolytic cell for containing the electrolytic solution. The tantalum sheet is used as the anode electrode and the platinum sheet is used as the cathode electrode to be fixed in the electrolytic cell containing the electrolytic solution. , the anode electrode and the cathode electrode are fixed to the electrolytic cell through metal clips, wherein one end of the anode electrode and the cathode electrode is immersed in the electrolyte solution, and the other end is exposed to the liquid surface of the electrolyte solution to connect with the positive and negative electrodes of the adjustable DC power supply . The liquid level of the electrolyte solution is kept at 2 / 3 of the height of the electrolytic cell (this is ...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is: the concentration of tetraethylammonium chloride for preparing the electrolytic solution is 0.5mol / L, the purity of ethanol is 94%, the inter-electrode distance between the tantalum sheet and the platinum sheet is 5cm, and the electrolytic corrosion voltage is 20V, electrolytic corrosion time is 80min.

Embodiment 3

[0042] The difference between this example and Example 1 is that the concentration of tetraethylammonium chloride used to prepare the electrolyte solution is 1mol / L, the purity of ethanol is 96%, the inter-electrode distance between the tantalum sheet and the platinum sheet is 10cm, and the electrolytic corrosion voltage is 40V , The electrolytic corrosion time is 40min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com