Transverse superjunction structure gallium nitride HEMT device and manufacturing method thereof

A manufacturing method and technology of gallium nitride, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of device self-heating effect, two-dimensional electron gas scattering, uneven electric field distribution in the drift region, etc. The effect of breakdown voltage, reduction of lateral scattering, reduction of self-heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0040] Such as Figure 1-8 Shown, the inventive method comprises the steps:

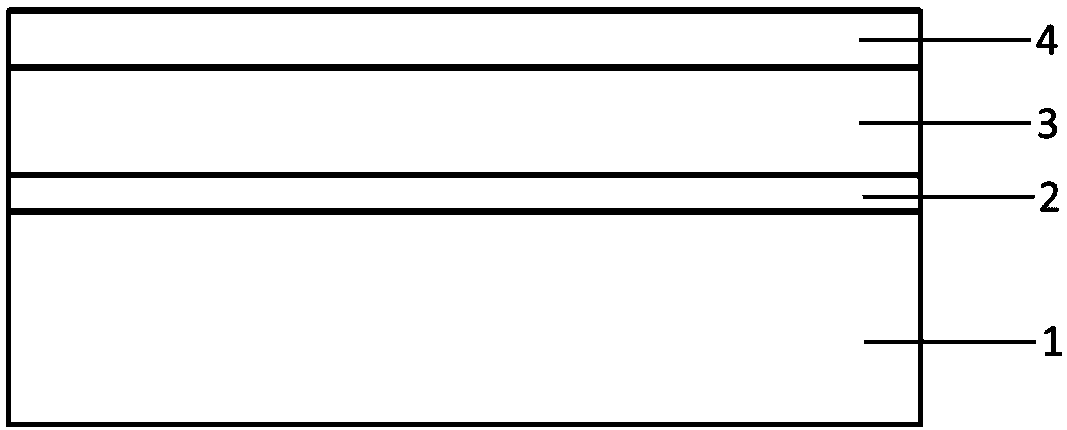

[0041] Step 1. If figure 1 As shown, a 300nm AlN layer 2, a 2μm GaN buffer layer 3, and a 100nm GaN channel layer 4 are epitaxially grown on a prepared silicon substrate 1 by PECVD (Plasma Enhanced Chemical Vapor Deposition) in sequence.

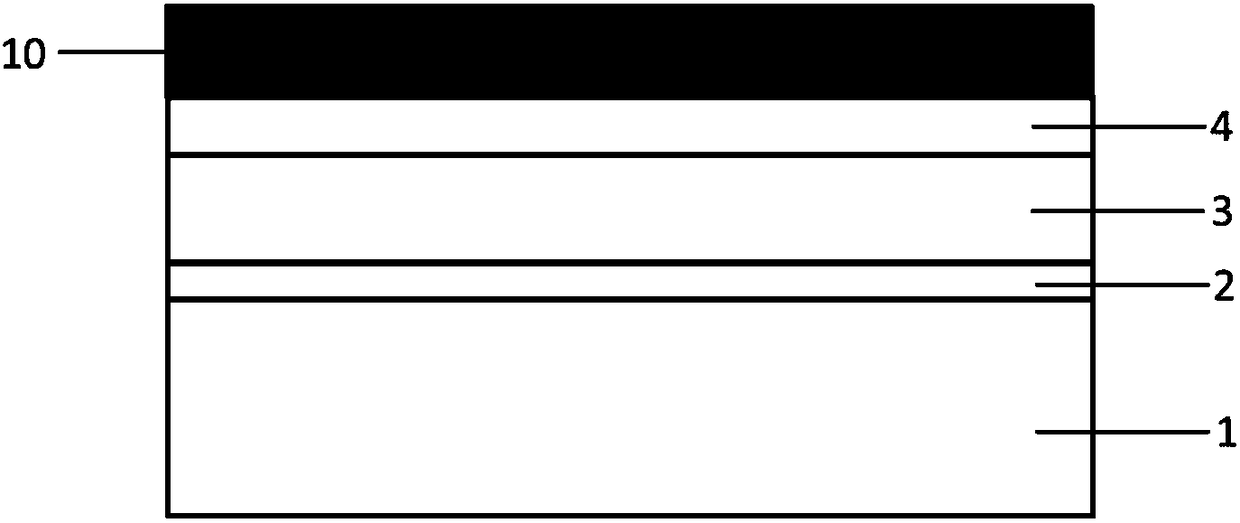

[0042] Step 2. coat a thick photoresist 10 on the epitaxial wafer obtained in step S1 as an ion implantation barrier such as figure 2 As shown, the photoresist thickness is 1 μm.

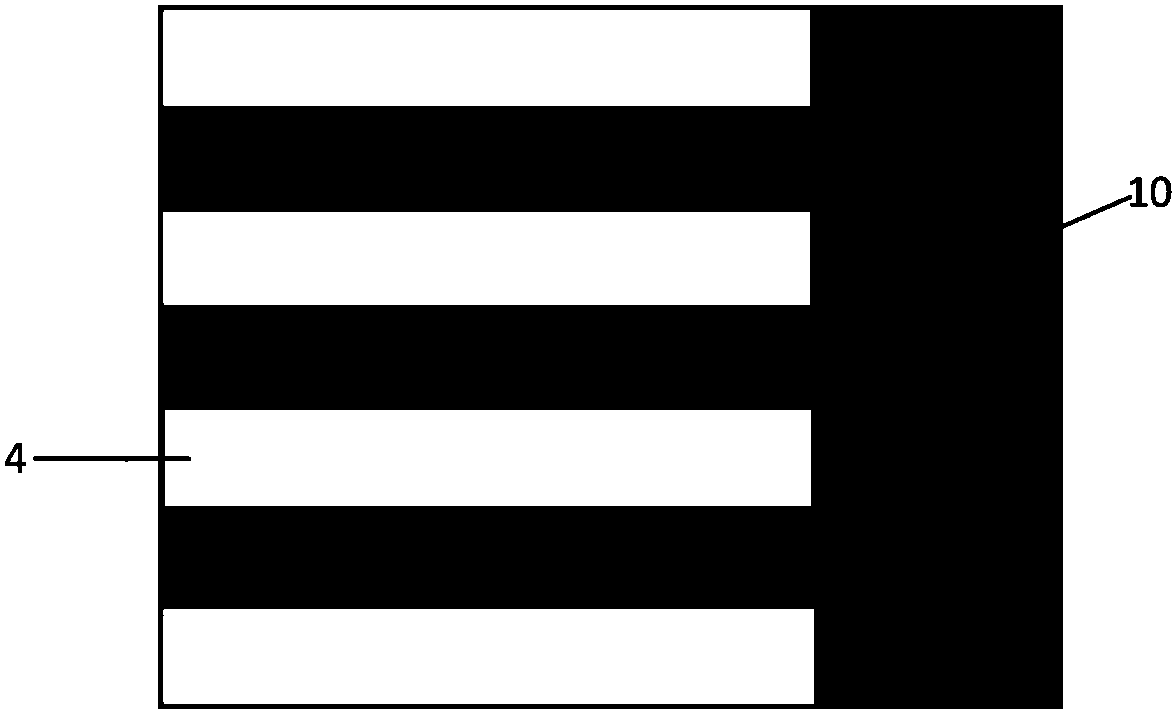

[0043] Step 3. Expose and develop the photoresist, such as image 3 As shown, the region of the GaN channel layer 4 that needs to be doped is exposed.

[0044] Step 4. Perform Mg ion implantation to form periodically spaced strip-shaped P-type doped regions 9 along the gate width direction in the GaN channel layer 4, such as Figure 4 and 5 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com