A kind of lithium-ion battery negative electrode material self-coating precursor and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increased cost, high cost and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

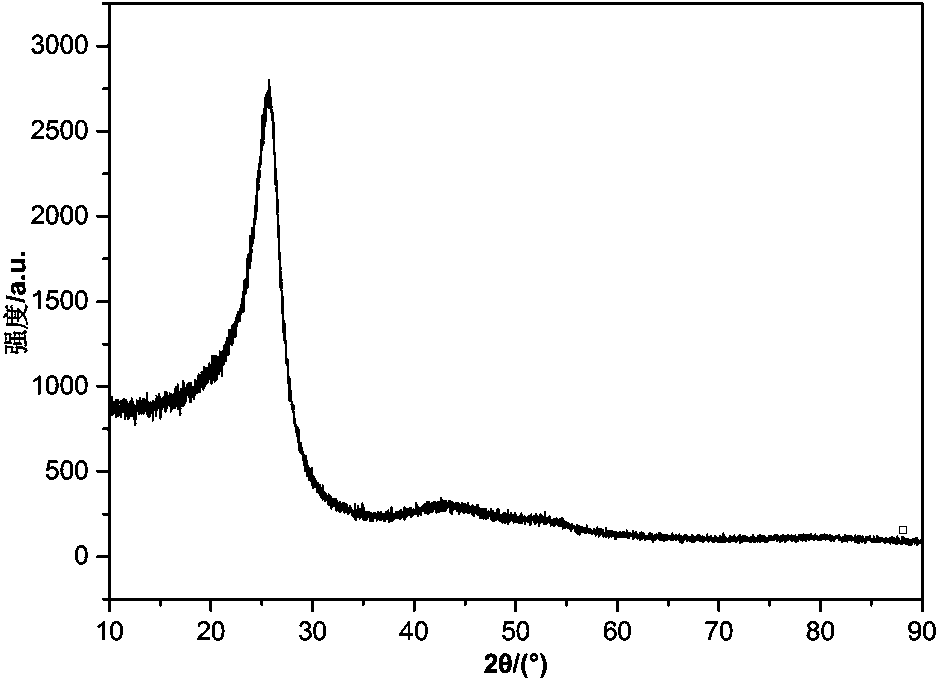

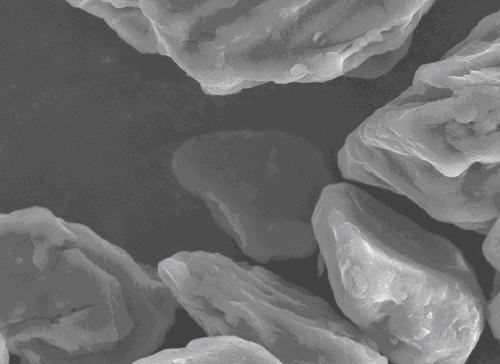

Embodiment 1

[0023] Use petroleum residue oil with an aromatic content of 30%-50% as the primary raw material to remove inorganic impurities and primary quinoline insolubles, control ash content ≤ 0.1%, sulfur content ≤ 0.4%, QI ≤ 0.1%, and then carry out in the reactor For the dehydrogenation polycondensation reaction, the reaction temperature was controlled at 400°C, the reaction time was 4h, the heating rate was 2°C / min, and the pressure inside the kettle was 0.1Mpa. The reaction process is carried out under an inert atmosphere condition, and stirring is required during the reaction process. After the reaction is completed, the intermediate product of the precursor of the negative electrode material is obtained. This precursor intermediate product is observed under a polarizing microscope as a wide-area body intermediate phase structure, and the XRD pattern is a diffuse diffraction peak. The obtained precursor intermediate product is crushed and spheroidized Treatment, control the parti...

Embodiment 2

[0025] Using FCC oil slurry as raw material, dehydrogenation polycondensation reaction was carried out in a reactor, the reaction temperature was controlled at 500°C, the reaction time was 6h, the heating rate was 6°C / min, and the pressure inside the kettle was 0.3Mpa. The reaction process is carried out under an inert atmosphere condition, and stirring is required during the reaction process. After the reaction is completed, the precursor intermediate product is obtained. This precursor intermediate product is observed under a polarizing microscope as a wide-area body intermediate phase structure, and the XRD pattern is a diffuse diffraction peak. The obtained precursor intermediate product is crushed and spheroidized. The particle size is 5-20um and the aspect ratio is 1-1.5 to obtain the precursor micropowder; then the precursor micropowder is heated to 450°C under normal pressure and inert atmosphere conditions, the surface will be partially melted but there will be no flui...

Embodiment 3

[0027] Using coal tar as raw material, dehydrogenation polycondensation reaction is carried out in a reactor, the reaction temperature is controlled at 600°C, the reaction time is 8h, the heating rate is 10°C / min, and the pressure inside the kettle is 0.5Mpa. The reaction process is carried out under an inert atmosphere condition, and stirring is required during the reaction process. After the reaction is completed, the precursor intermediate product is obtained. This precursor intermediate product is observed under a polarizing microscope as a wide-area body intermediate phase structure, and the XRD pattern is a diffuse diffraction peak. The obtained precursor intermediate product is crushed and spheroidized. The particle size is 5-20um, the aspect ratio is 1-1.5, and the precursor powder is obtained; then the precursor powder is heated to 400°C under normal pressure and inert atmosphere conditions, the surface will be partially melted but will not appear fluidity, melting Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com