Uric acid-lowering flavored black tea drink

A technology for reducing uric acid and flavor, applied in the direction of tea extraction, etc., can solve the problems of light taste, loss of aromatic substances, turbidity and precipitation, etc., and achieve the effect of enriching nutrients, increasing sweetness and reducing uric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

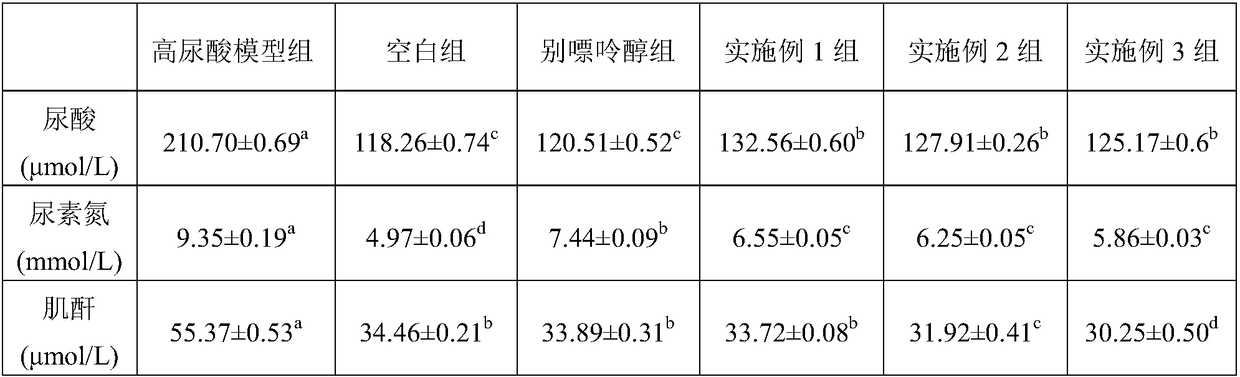

Embodiment 1

[0020] Take 6 parts of Fuzhuan brick tea, 2 parts of Liubao tea, 2 parts of Pu'er cooked tea, 2 parts of flower-flavored black tea, 2 parts of lotus leaf and 2 parts of Cyclocarya paliurus as raw materials, mix them by weight, and grind them to get raw material mixed powder. Ratio of mixed powder plus 8mL deionized water Add deionized water to the raw material mixed powder, leaching twice at 90°C for 45 minutes each time, after each leaching, first filter through stainless steel mesh, 200 mesh nylon cloth bag, and then pass through High-speed tubular centrifuge is centrifugally filtered with the rotating speed of 14000r / min, gets filtrate, merges filtrate 2 times, obtains clear and transparent tea soup; In this tea soup, add the flavor auxiliary material bag that is 0.04% of tea soup weight (by weight percentage by lemon slice 30 %, Kunlun snow chrysanthemum 40% and honeysuckle 30%), after soaking at 90 ℃ for 35min, take out the flavor auxiliary material bag; then add 0.02% swe...

Embodiment 2

[0022] Take 8 parts of Fuzhuan brick tea, 4 parts of Liubao tea, 4 parts of Pu'er ripe tea, 4 parts of flower-flavored black tea, 4 parts of lotus leaf and 4 parts of Cycarya paliurus as raw materials, mix them by weight, and grind them to obtain raw material mixed powder. Ratio of mixed powder to 12mL deionized water Add deionized water to the raw material mixed powder, leaching twice at 100℃, each time for 35min, after each leaching, first filter through stainless steel mesh, 200 mesh nylon bag, and then through High-speed tubular centrifuge is centrifugally filtered with the rotating speed of 16000r / min, gets filtrate, merges filtrate 2 times, gets clear and transparent tea soup; In this tea soup, add the flavor auxiliary material bag that is 0.08% of tea soup weight (by weight percentage by lemon slice 50 %, Kunlun snow chrysanthemum 30% and honeysuckle 20%), after soaking at 100 ℃ for 25min, take out the flavor auxiliary material bag; then add 0.04% sweetener (extracted by...

Embodiment 3

[0024] Take 7 parts of Fuzhuan brick tea, 3 parts of Liubao tea, 3 parts of Pu'er cooked tea, 3 parts of flower-flavored black tea, 3 parts of lotus leaf and 3 parts of Cycarya paliurus as raw materials in parts by weight, mix them, and grind them to obtain raw material mixed powder. Ratio of mixed powder plus 10mL deionized water Add deionized water to raw material mixed powder, leaching twice at 95°C, 40 minutes each time, after each leaching, first filter through stainless steel mesh, 200 mesh nylon cloth bag, and then pass through High-speed tubular centrifuge is centrifugally filtered with the rotating speed of 15000r / min, gets filtrate, merges 2 filtrates, obtains clear and transparent tea soup; In this tea soup, add the flavor auxiliary material bag that is tea soup weight 0.06% (by weight percentage by lemon slice 40 %, Kunlun snow chrysanthemum 20% and honeysuckle 40%), after soaking at 95°C for 30min, take out the flavor auxiliary material bag; add 0.03% sweetener (ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com