A kind of wastewater treatment method produced by thiosemicarbazide

A technology of thiosemicarbazide and wastewater treatment, which is applied in natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as improper wastewater treatment, and achieve high utilization rate, high resource utilization rate, and energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Treat 1 ton of waste water produced by thiosemicarbazide, and detect the contents of each component as follows: ammonium chloride: 18%; ammonium thiocyanate: 12%, thiosemicarbazide 3.0%, and dithiocarbazone 1.0%.

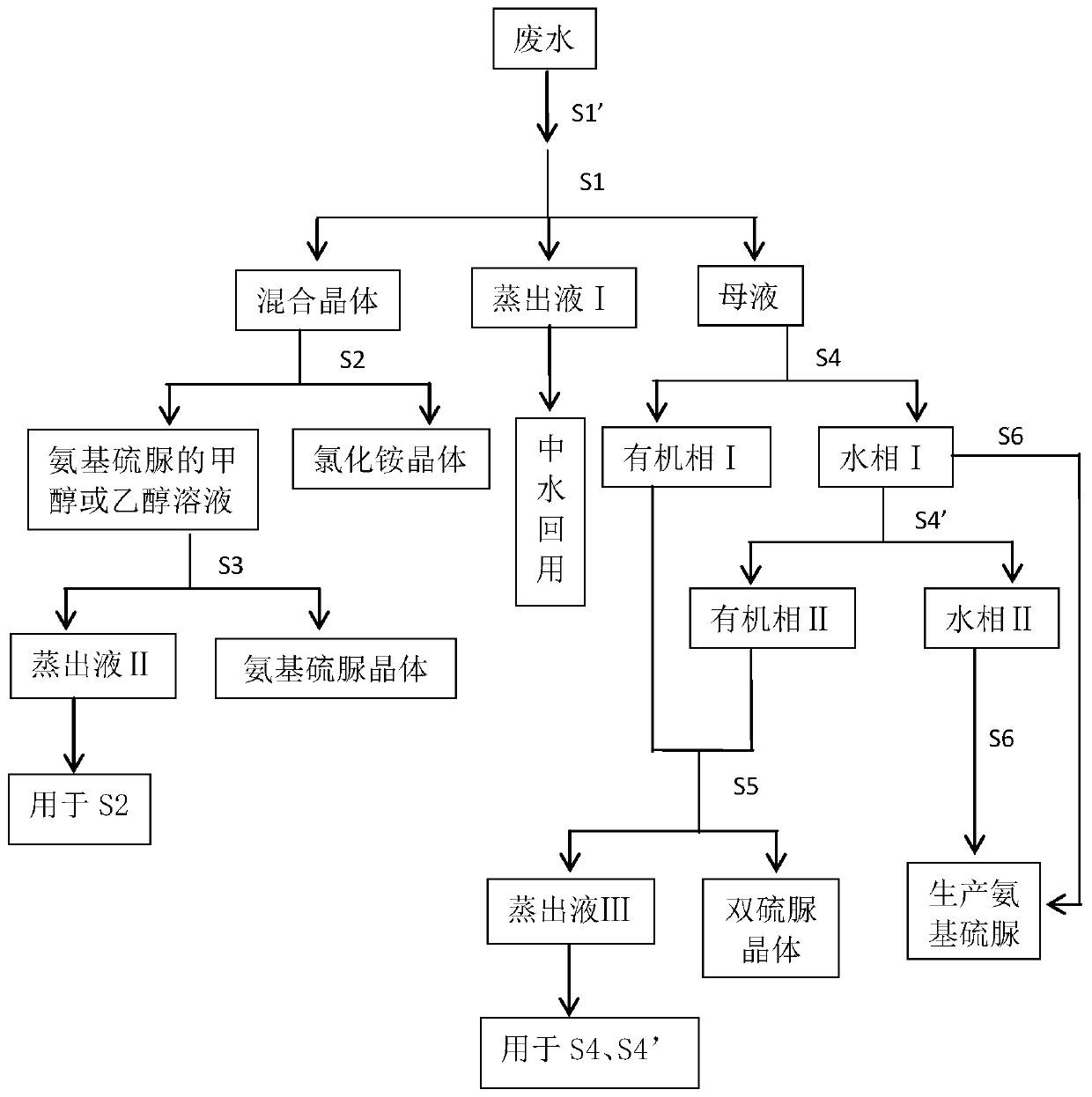

[0040] Its wastewater treatment method comprises the following steps:

[0041] S1', decolorization: add 1 kg of activated carbon, stir at 20-50°C for 1.5 hours, filter, and carry out subsequent operations on the filtrate, activated carbon can be used mechanically for 2-3 times.

[0042] S1. Preliminary concentration: 530 kg of water is removed by evaporation and concentration. At this time, a large amount of ammonium chloride crystals are precipitated. When the content of ammonium thiocyanate in the water phase is monitored to be 28-45%, the first concentration is completed, and 180 kg of mixed crystals are separated, and the remaining liquid is the mother liquor. . The evaporated condensate in this step can be used as production process water for preparing ...

Embodiment 2

[0050]Treat 1 ton of waste water produced by thiosemicarbazide, and detect the contents of each component as follows: ammonium chloride: 17%; ammonium thiocyanate: 10%, thiosemicarbazide 2.7%, and dithiocarbazone 0.8%.

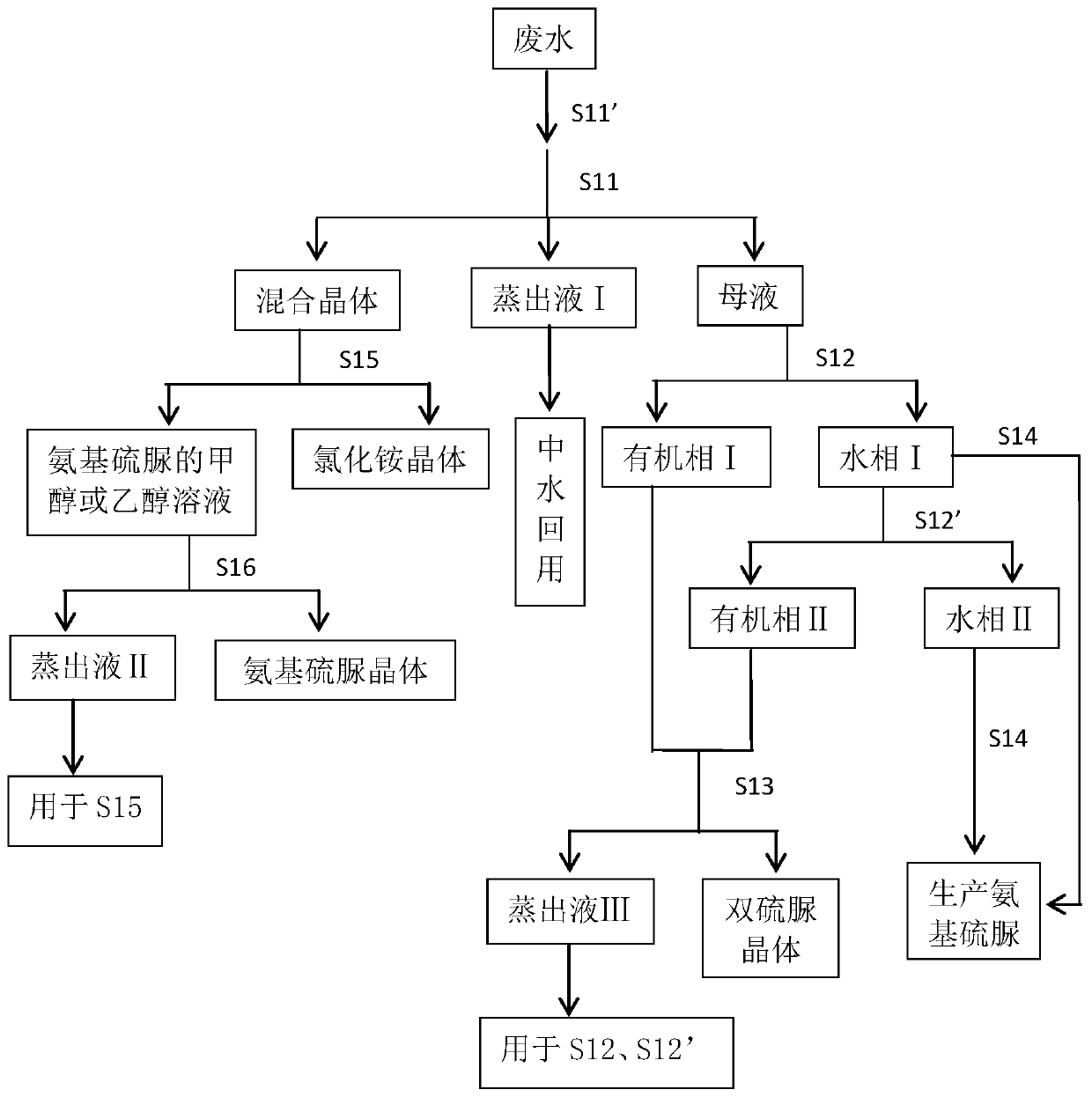

[0051] Its wastewater treatment method comprises the following steps:

[0052] S11', decolorization: add 1 kg of activated carbon, stir at 20-50°C for 1 hour, filter, and carry out subsequent operations on the filtrate, the activated carbon can be used mechanically for 2-3 times.

[0053] S11. Preliminary concentration: 420 kg of water is removed by evaporation and concentration. At this time, a large amount of ammonium chloride crystals are precipitated. When the content of ammonium thiocyanate in the water phase is monitored to be 28-45%, the first concentration is completed, and 150 kg of mixed crystals are separated, and the remaining liquid is the mother liquor. . The evaporated condensate in this step can be used as production process water for preparin...

Embodiment 3

[0061] Treat 1 ton of waste water produced by thiosemicarbazide, and detect the contents of each component as follows: ammonium chloride: 23%; ammonium thiocyanate: 15%, thiosemicarbazide 3.2%, and dithiocarbazone 1.1%.

[0062] Its wastewater treatment method comprises the following steps:

[0063] S1. Preliminary concentration: 600 kg of water is removed by evaporation and concentration. At this time, a large amount of ammonium chloride crystals are precipitated. When the content of ammonium thiocyanate in the water phase is monitored at 28-45%, the first concentration is completed, and 190 kg of mixed crystals are separated, and the remaining liquid is the mother liquor. . The evaporated condensate in this step can be used as production process water for preparing ammonium thiocyanate solution, rinsing products, etc.

[0064] S2. Extraction of thiosemicarbazide: at normal temperature, fully mix the mixed crystals with 150 kg of methanol, separate 162 kg of ammonium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com