Sunscreen cosmetic composition containing film-forming agents and microsphere granules and preparation method of sunshine cosmetic composition

A technology for cosmetic compositions and film-forming agents, applied in cosmetic preparations, cosmetics, cosmetic preparations, etc., can solve problems such as poor spreadability, greasy sunscreen cosmetics, etc., to improve durable activity, prolong skin radiation time, and improve UV protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

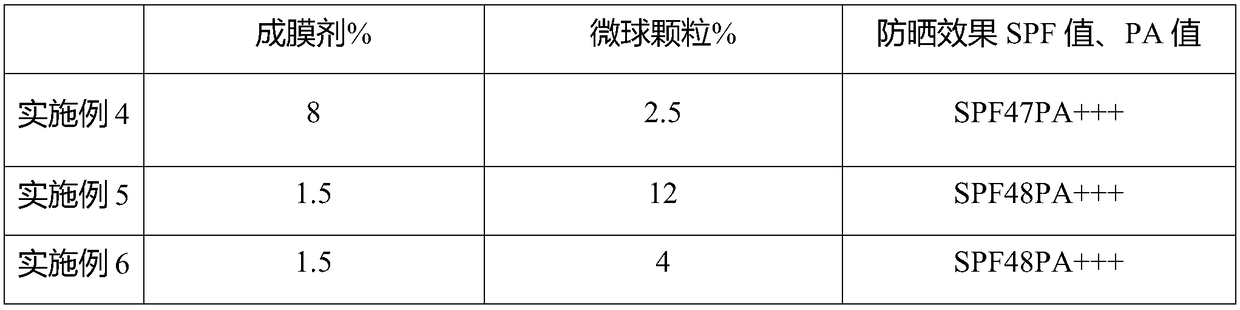

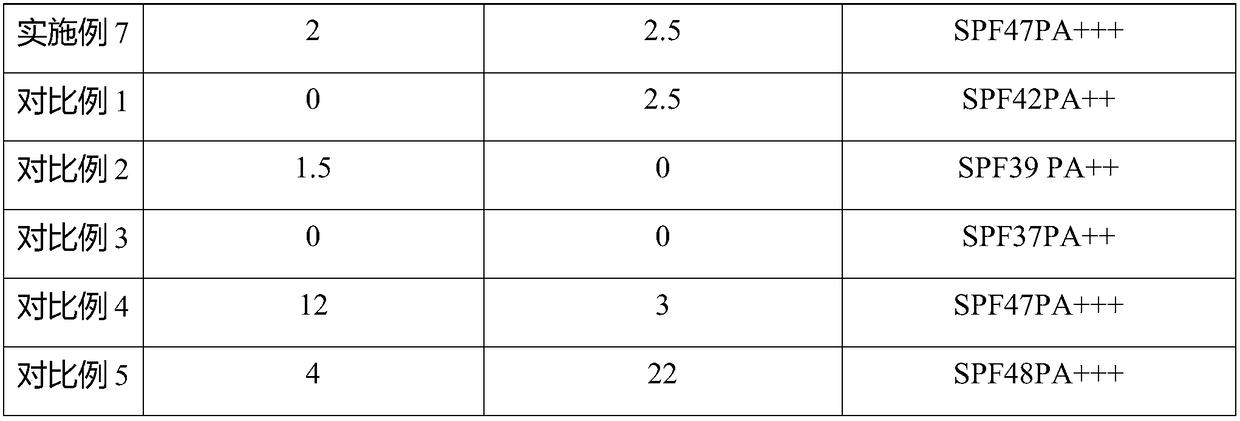

Examples

preparation example Construction

[0038] The preparation method of the sunscreen cosmetic composition: 1) Add the components belonging to the oil phase into the oil phase pot, stir and heat to 82-87°C at a rotation speed of 10-50rpm, and fully stir until uniform to obtain the oil phase mixture;

[0039] 2) Add the components belonging to the water phase into the water phase pot, stir and heat to 82-87°C at a rotation speed of 10-50rpm, and stir well until uniform to obtain the water phase mixture;

[0040] 3) Pump the oil phase mixture and the water phase mixture into the vacuum emulsification pot through the filter valve in turn, stir at a speed of 30-35rpm, then homogenize at a speed of 2500-3200rpm until the emulsification is uniform, and then reduce the stirring speed to 10~30rpm, cool down to 45°C, add additives, continue to stir until uniform and then discharge;

[0041] 4) Fill it after passing the test, and it will be ready.

Embodiment 1

[0042] Embodiment 1 sunscreen cosmetic composition

[0043] The sunscreen cosmetic composition of the present embodiment is made up of following components: 1) oil phase: octocrylene 5.00%, C12-15 alcohol benzoate 2.00%, ethylhexyl salicylate 6.00%, butylmethoxy Dibenzoyl Methane 5.00%, Behenyl Alcohol (and) Polyglyceryl-10 Pentastearate (and) Sodium Stearoyl Lactylate 2.00%, Titanium Dioxide (and) Dimethicone 4.50%, Cyclopentasiloxane 5.00%, Dimethicone 3.00%, Polyvinylpyrrolidone / Eicosene Copolymer 2.00%;

[0044] 2) Water phase: water 50.20%, butylene glycol 8.00%, phenylbenzimidazole sulfonic acid 3.00%, styrene / acrylic acid (ester) copolymer 0.50%, cetyl potassium phosphate 1.50%, xanthan gum 0.20%, Tetrasodium EDTA 0.05%;

[0045] 3) Additives: aminomethyl propanol 1.05%, phenoxyethanol (and) ethylhexylglycerin 0.60%, 1,3-propanediol (and) caprylyl glycol 0.30%, essence 0.10%.

Embodiment 2

[0046] Embodiment 2 Sunscreen cosmetic composition

[0047] The sunscreen cosmetic composition of the present embodiment is made up of following components: 1) oil phase: 5.00% of ethylhexyl methoxycinnamate, 6.00% of cyclopentasiloxane, 1.50% of cetearyl alcohol , Ethylhexyl Salicylate 5.00%, Ethylhexyl Triazone 3.50%, Cyclopentasiloxane (and) Trimethylsiloxysilicate 1.50%, Diethylaminohydroxybenzoate Hexyl Acylbenzoate 2.00%, Octylmethicone 1.00%;

[0048] 2) Water phase: water 56.30%, polysorbate-200.50%, potassium cetyl phosphate 0.80%, styrene / acrylic acid (ester) copolymer 2.50%, polyglycerol-10 myristate 0.50%, Sodium Hyaluronate 0.10%, Betaine 1.50%, Ammonium Acryloyl Dimethyl Taurate / VP Copolymer 0.60%, Acrylates / C10-30 Alkyl Acrylate Crosspolymer 0.40%, EDTA Di Sodium 0.10%, Propylene Glycol 8.00%, Xanthan Gum 0.15%, Water (and) Methylene Bis-Benzotriazolyl Tetramethylbutylphenol (and) Decyl Glucoside (and) Propylene Glycol (and) Xanthan Glue 2.00%;

[0049] 3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com