Exhaust purification cellular catalyst for enamelling machine and method of producing the same

A technology of honeycomb catalyst and enamelling machine, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve high exhaust back pressure and shorten catalyst service life , Catalyst poisoning and other problems, to achieve the effect of improving durable activity, lowering temperature, and small air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

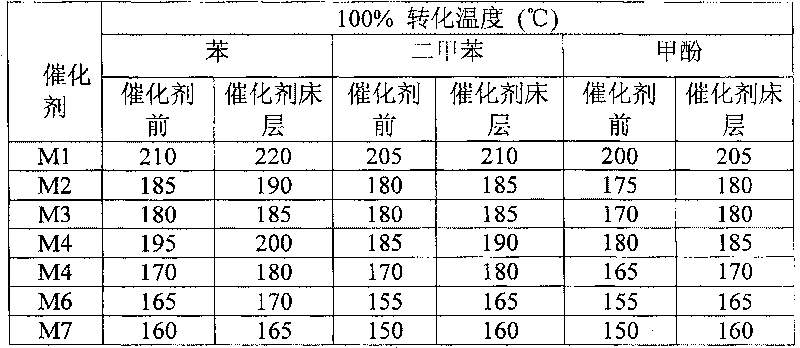

[0022] Preparation of enameled machine exhaust gas purification metal honeycomb catalyst M1: Select 50 mesh metal carrier for metal honeycomb, and the shape is a cube of 80mm × 80mm × 80mm, and heat it at 800 ℃ for 2h; The liquid water is separated out, and the weight of the added water is recorded 32g; the palladium nitrate solution containing 5g of palladium is weighed, diluted to 318.4g, and the cerium-zirconium solid solution of 995g of palladium nitrate is supported by the equal volume dipping method; the gamma-alumina of 4000g is weighed; Then weigh 8000 g of deionized water; mix γ-alumina, deionized water and the cerium-zirconium solid solution loaded with palladium nitrate into a container with a stirrer, and stir to obtain a suspension; the suspension is ground by a ball mill to Granularity D 90 = 20 microns; immerse the above-mentioned pretreated metal honeycomb carrier in the slurry, stay for 2 seconds, and pull out at a speed of 30 mm per second; dry the metal hone...

Embodiment 2

[0025] Preparation of enameled machine exhaust gas purification metal honeycomb catalyst M2: The specific preparation method is basically the same as that of Example 1 of this part, the difference is that the metal honeycomb chooses a 200 mesh metal carrier. The results of catalyst activity evaluation and bed temperature test are shown in Table 1.

Embodiment 3

[0027] Preparation of enameled machine exhaust gas purification metal honeycomb catalyst M3: The specific preparation method is basically the same as that of Example 1 of this part, the difference is that the metal honeycomb selects a 600 mesh metal carrier. The results of catalyst activity evaluation and bed temperature test are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com