Photocatalytic titanium dioxide, graphene oxide and straw composite adsorbent and preparing method and application thereof

A titanium dioxide and composite adsorption technology, which is applied in the field of dye pollution and environmental restoration, can solve the problems of not meeting the environmental protection concept of green economy and complex preparation methods, and achieve the effect of simple adsorption process, simple preparation process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

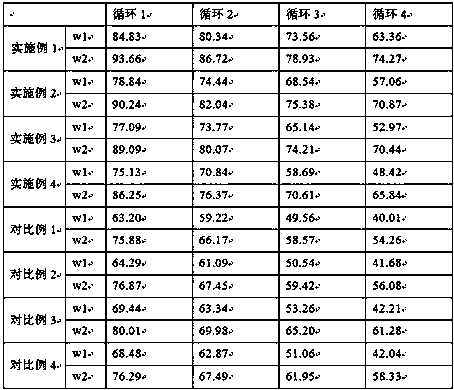

Examples

Embodiment 1

[0037] 1) Preparation of activated straw core powder

[0038] a. Dry the straw at 40°C for 24 hours, then peel off the straw epidermis, take the straw core and cut it into 1.5-2.5 cm segments, crush it, pass through a 100-mesh sieve, and obtain the straw core powder;

[0039] b. Add straw core powder to 10% ZnCl 2 In an aqueous solution, the ratio of solid to liquid is 0.05g / mL, and stirred in a water bath at 75°C for 1 hour to obtain a colloid;

[0040] c. Suction filter the colloid, wash three times with ethanol and distilled water successively, and dry to obtain activated straw core powder;

[0041] 2) Preparation of photocatalytic titanium dioxide graphene oxide straw composite adsorbent

[0042] a. Disperse 0.2 parts by weight of titanium dioxide in water, ultrasonically disperse for 20 minutes, and stir every 5 minutes during the ultrasonic process to obtain a titanium dioxide dispersion; wherein the concentration of the titanium dioxide dispersion is 0.01 g / mL;

[0...

Embodiment 2

[0053] 1) Preparation of activated straw core powder

[0054] a. Dry the straw at 40°C for 24 hours, then peel off the straw skin, take the straw core and cut it into 1.5-2.5 cm segments, crush it, and pass it through a 100-mesh sieve to obtain the straw core powder;

[0055] b. Add straw core powder to 10% ZnCl 2 In an aqueous solution, the ratio of solid to liquid is 0.1 g / mL, and stirred in a water bath at 75 °C for 1 h to obtain a colloid;

[0056] c. Suction filter the colloid, wash three times with ethanol and distilled water successively, and dry to obtain activated straw core powder;

[0057] 2) Preparation of photocatalytic titanium dioxide graphene oxide straw composite adsorbent

[0058] a. Disperse 0.3 parts by weight of titanium dioxide in water, ultrasonically disperse for 20 minutes, and stir every 5 minutes during the ultrasonic process to obtain a titanium dioxide dispersion; the concentration of the titanium dioxide dispersion is 0.01 g / mL;

[0059] b. A...

Embodiment 3

[0068] 1) Preparation of activated straw powder and straw core powder

[0069] a. Dry the straw at 40°C for 24 hours, then peel off the straw epidermis, take the straw core and cut it into 1.5-2.5 cm segments, crush it, and pass it through a 100-mesh sieve to obtain the straw core powder;

[0070] b. Add straw core powder to 10% ZnCl 2 In an aqueous solution, the ratio of solid to liquid is 0.2 g / mL, and stirred in a water bath at 75 °C for 1 hour to obtain a colloid;

[0071] c. Suction filter the colloid, wash three times with ethanol and distilled water successively, and dry to obtain activated straw core powder;

[0072] 2) Preparation of photocatalytic titanium dioxide graphene oxide straw composite adsorbent

[0073] a. Disperse 0.4 parts by weight of titanium dioxide in water, ultrasonically disperse for 20 minutes, and stir every 5 minutes during the ultrasonic process to obtain a titanium dioxide dispersion; wherein the concentration of the titanium dioxide dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com