Laser preparation device and method for in-situ synthesis of TiC-reinforced titanium-based composite material

A titanium-based composite material and in-situ synthesis technology, which is applied in the direction of additive processing, metal material coating technology, additive manufacturing, etc., can solve the problems of difficult uniform dispersion, solve the problem of reinforced phase agglomeration, solve the problem of poor interface bonding strength, Strong real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

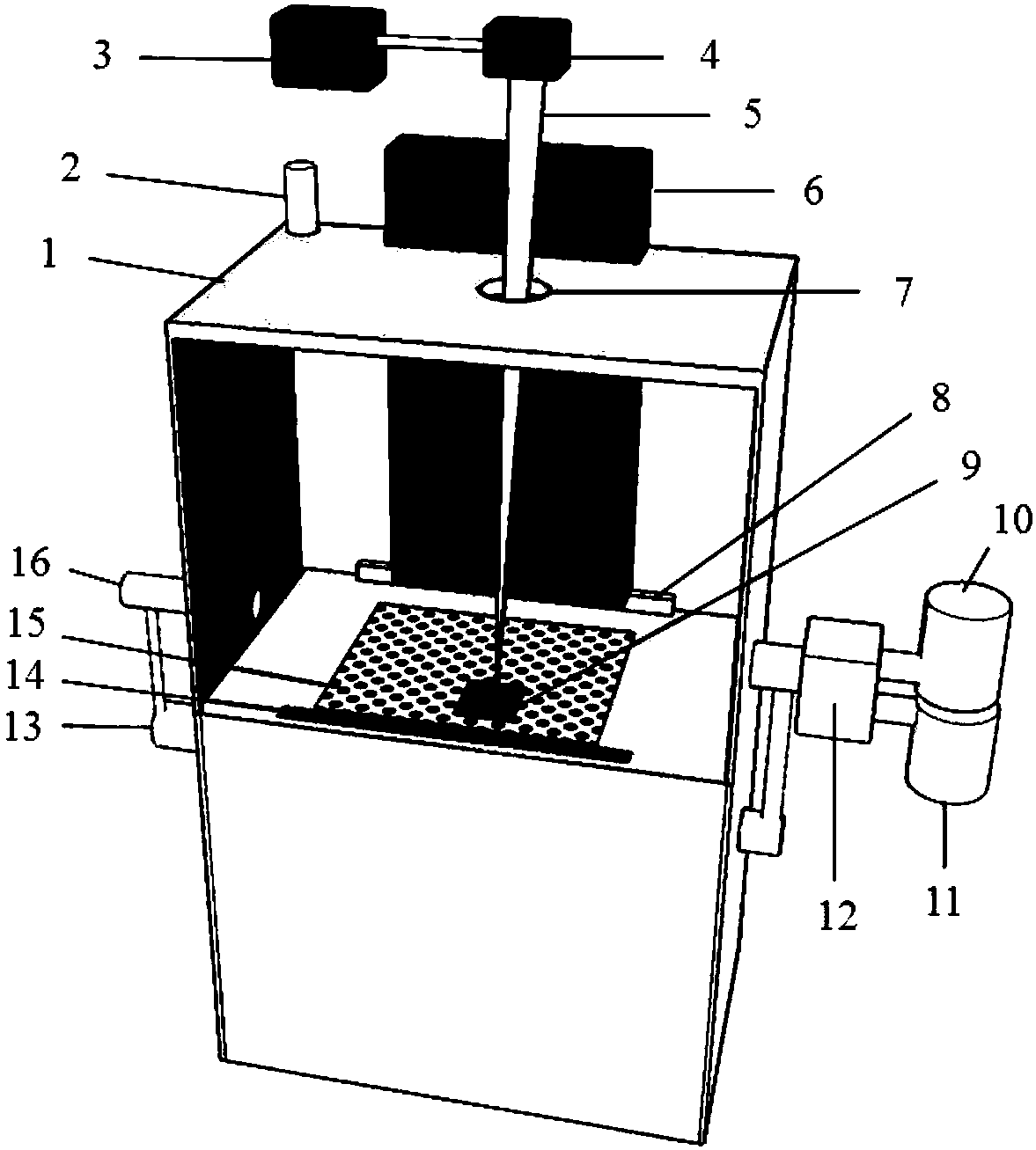

[0036] Example 1. Laser preparation device for in-situ synthesis of TiC-reinforced titanium-based composite materials

[0037] Laser preparation device for in-situ synthesis of TiC-reinforced titanium-based composites, with a structure such as figure 1 As shown, it includes numerical control system, atmosphere control system, powder feeding and spreading system (6), laser system and forming room (1); among them, the numerical control system is connected with laser (3), powder feeding and spreading system (6) and atmosphere control The system is connected, wherein the lower end of the powder feeding and spreading system (6) is provided with a scraper (8) for laying titanium alloy spherical powder; the forming chamber (1) is provided with a powder collection device (14) and a powder bed (15), forming A gas supply system and outlet II (2) are arranged outside the chamber (1). The gas supply system consists of a carbon source gas chamber (10), an inert gas chamber (11), a gas mixi...

Embodiment 2

[0040] Example 2. Laser preparation device for in-situ synthesis of TiC-reinforced titanium-based composites Method for in-situ synthesis of TiC-reinforced titanium-based composites

[0041] The method for synthesizing TiC reinforced titanium-based composite material in situ comprises the following steps:

[0042] (1) Start the atmosphere control system to purify the forming chamber. Carbon source gas and inert gas are mixed in the gas mixing chamber according to a certain concentration ratio and then enter the forming chamber, and circulate and disperse under the action of the gas circulation device;

[0043] (2) The powder feeding and spreading system controls the scraper to evenly lay a layer of titanium alloy spherical powder on the powder bed;

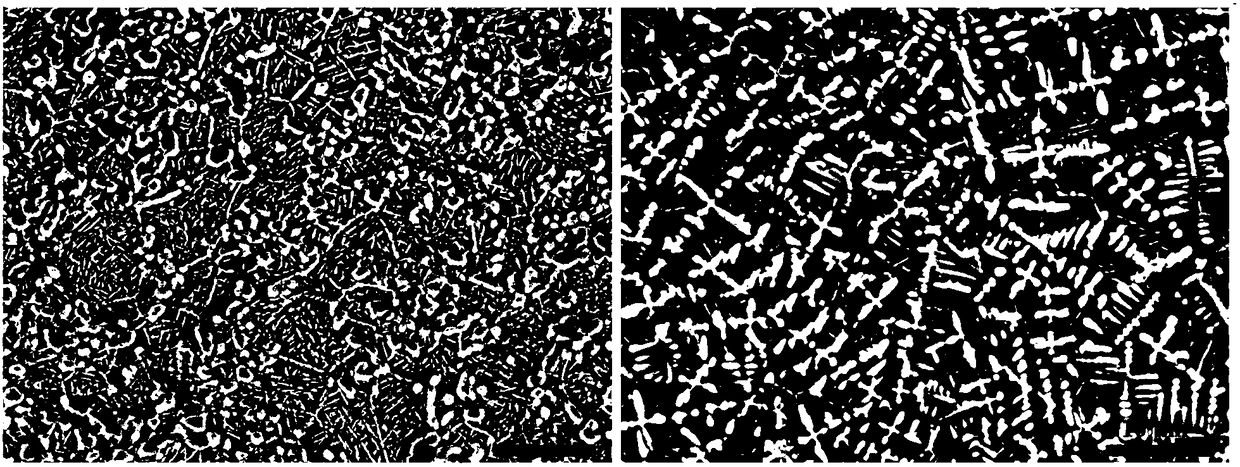

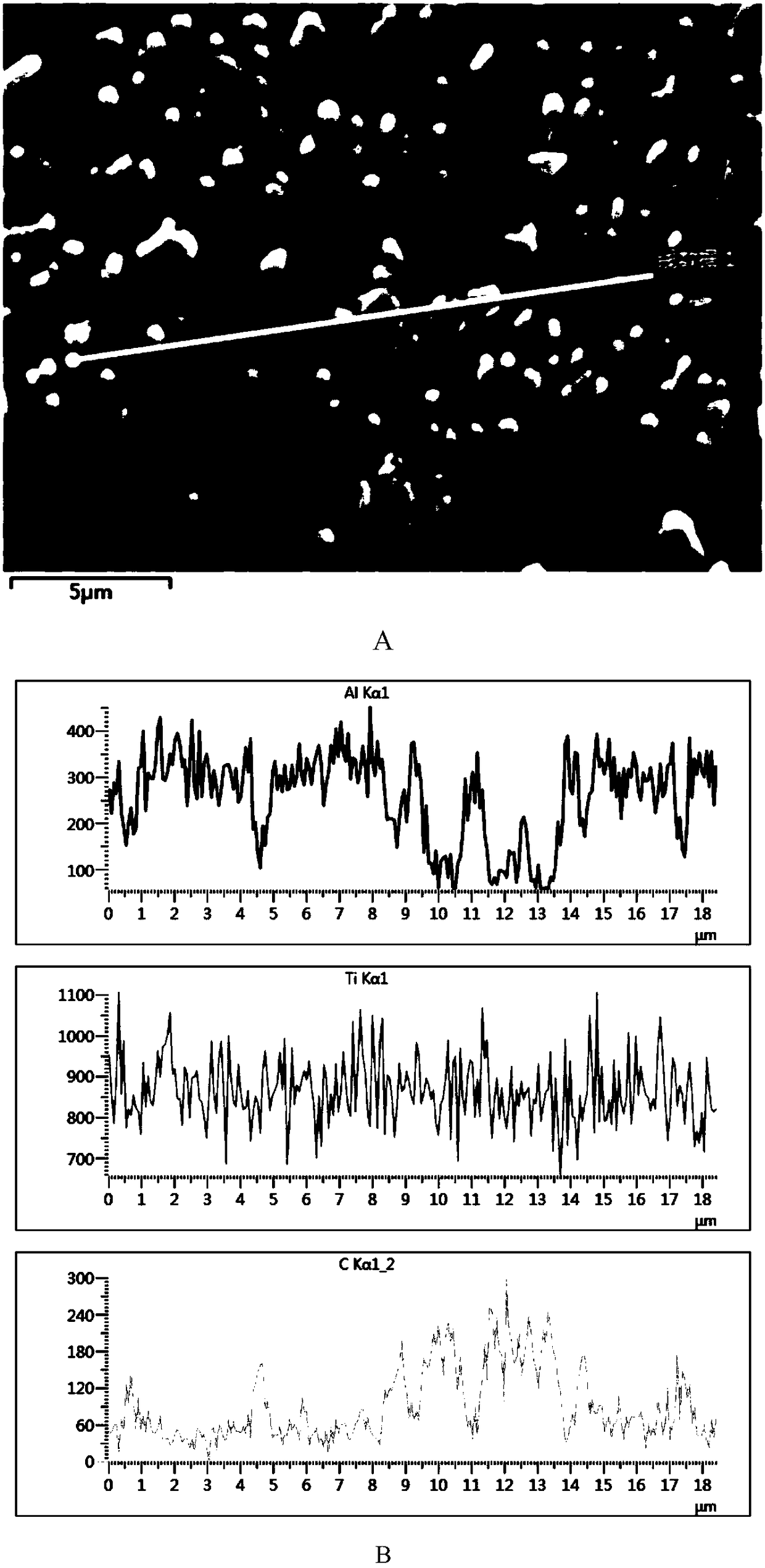

[0044] (3) According to the preset three-dimensional graphics file, the laser beam scans the metal powder to form a focused spot on the processing plane of the titanium alloy powder, and melts the titanium alloy powder to form a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com