Preparation method and use of Cox(OH)yM

A PO43-, product technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., can solve problems such as complex preparation processes, and achieve the effects of simple and easy operation, good electrochemical energy storage performance, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Co x (OH) y Preparation method of M, where M is F or Cl or PO 4 3- , Including the following steps:

[0033] (1) Mixed organic alcohol amine: CoM a ·NH 2 O was added to the organic alcohol amine solution and stirred for 30 minutes to completely dissolve to obtain a mixture; where M is F or Cl or PO 4 3- ; Wherein the organic alcohol amine is at least one of ethanolamine, diethanolamine, triethanolamine, and isopropanolamine.

[0034] (2) Reaction in the reactor: transfer the mixture to the autoclave for hydrothermal reaction. The hydrothermal reaction temperature is 160~200℃, and the reaction time is 6~24 hours. After the reaction, the product is washed by distillation and centrifugation. After at least one time, use ethanol to centrifuge at least one time, and then dry at 70 ℃, the obtained powdery product is Co x (OH) y M, where M is F or Cl or PO 4 3- .

Embodiment 2

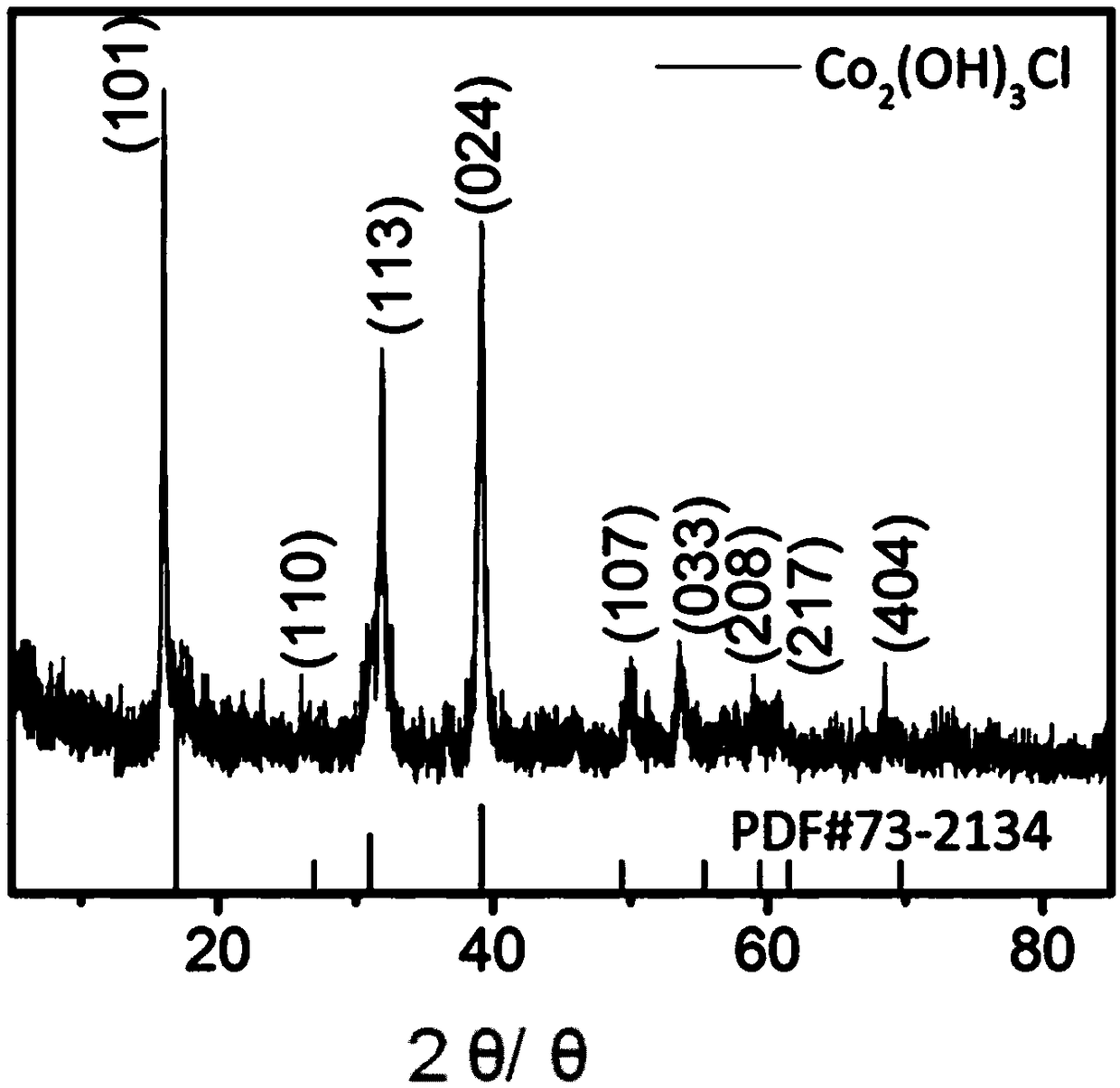

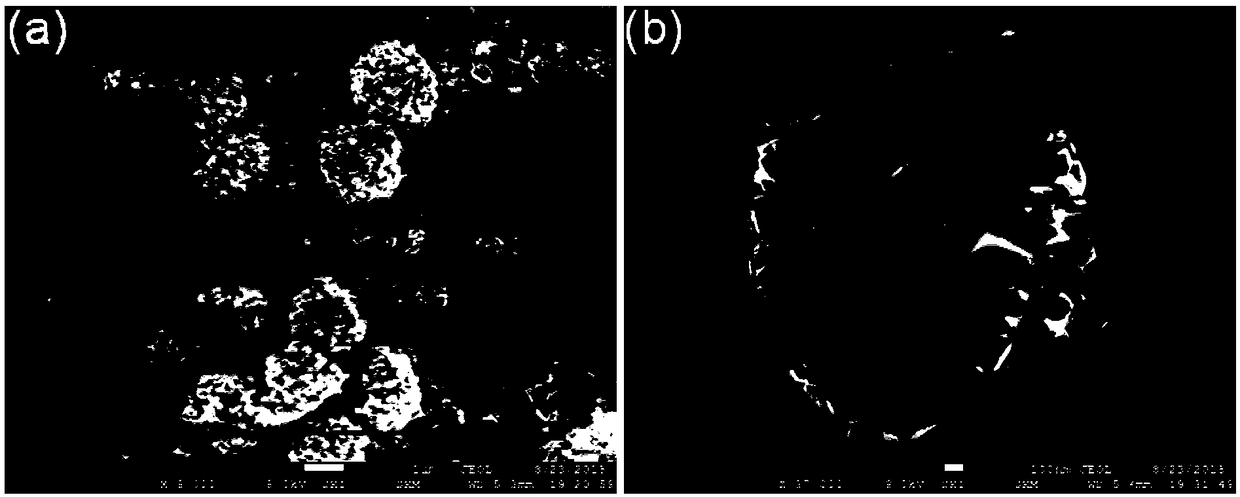

[0036] Co 2 (OH) 3 The preparation method of Cl includes the following steps:

[0037] (1) Mixed organic alcohol amine: Weigh 0.4 g of triethanolamine (TEOA for short) into a beaker containing 20 mL of distilled water, stir to dissolve, and obtain a prepared triethanolamine solution. 1mmol of CoCl 2 .6H 2 O was added to the prepared triethanolamine solution, stirred for 30 minutes to completely dissolve, to obtain a mixture;

[0038] (2) Reaction in the reactor: Transfer the mixture to the high-pressure reactor. The volume of the mixture accounts for about 60% of the total volume of the reactor. The hydrothermal reaction is carried out. The hydrothermal reaction temperature is 200°C and the reaction time is 24 hours. After the reaction, cool to room temperature naturally. After washing the product by distillation and centrifugation at least once, then washing it by ethanol centrifugation at least once, and then drying at 70℃ for 12 hours, the obtained powdery product is Co 2 (OH) 3...

Embodiment 3

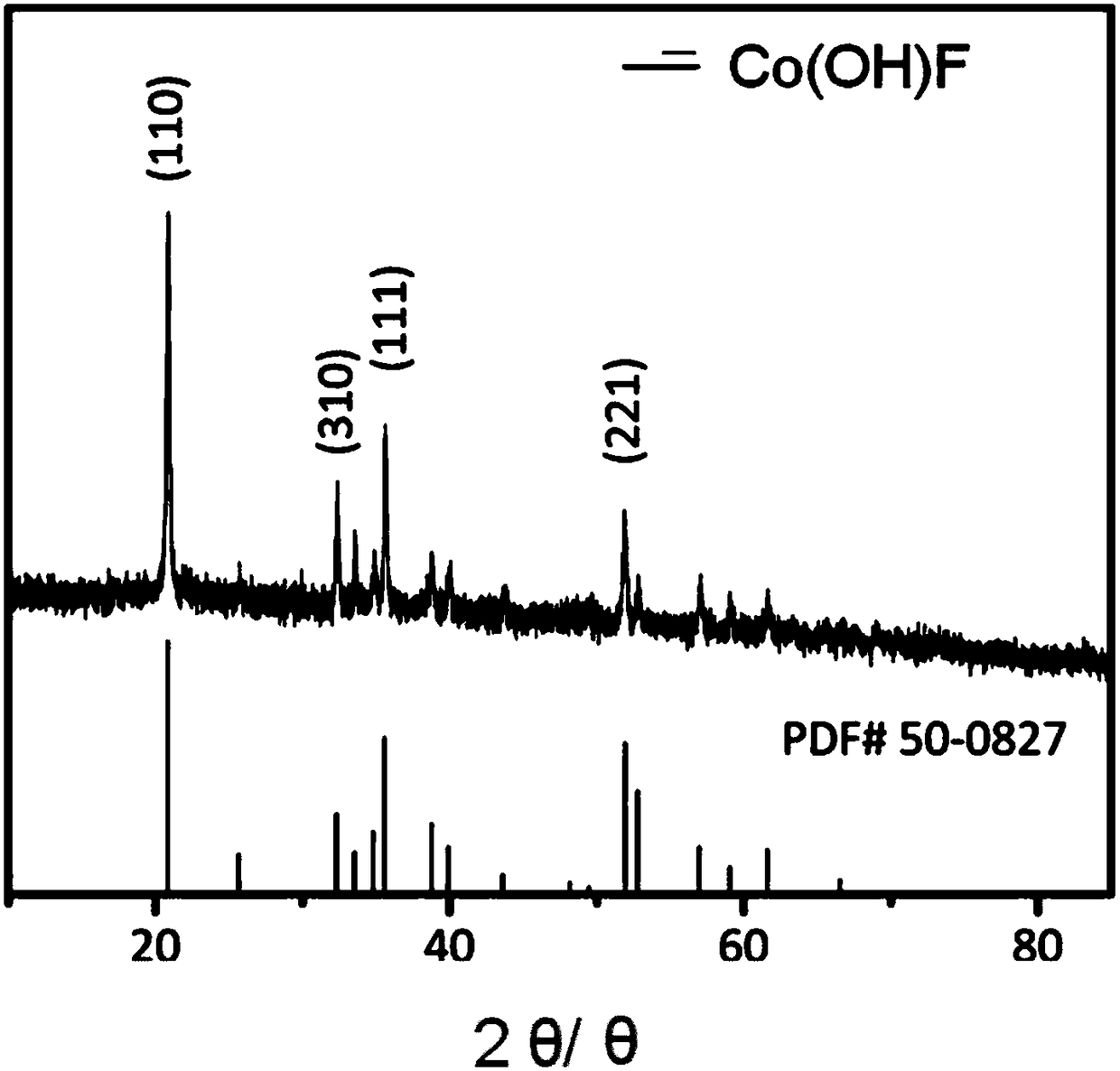

[0040] The preparation method of Co(OH)F includes the following steps:

[0041] (1) Mixed organic alcohol amine: Weigh 0.4 g of triethanolamine (TEOA for short) into a beaker containing 20 mL of distilled water, stir to dissolve, and obtain a prepared triethanolamine solution. 1mmol of CoF 2 Add it to the prepared triethanolamine solution and stir for 20 minutes to completely dissolve to obtain a mixture;

[0042] (2) Reaction in the reactor: Transfer the mixture to the high-pressure reactor. The volume of the mixture accounts for about 60% of the total volume of the reactor. The hydrothermal reaction is carried out. The hydrothermal reaction temperature is 200°C and the reaction time is 24 hours. After the reaction is over, the product is naturally cooled to room temperature, and the product is washed by distillation and centrifugation at least once, and then washed by ethanol centrifugation at least once, and then dried at 70° C. for 12 hours to obtain a powdered product of Co(OH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com