Device and method for preparing captan

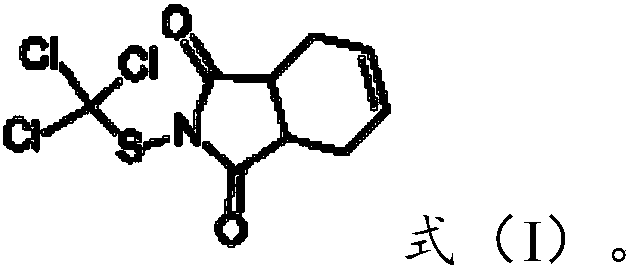

A technology for captandan and a reaction device, which is applied in the field of devices for preparing captandan, can solve the problems of cumbersome reaction steps, waste of water resources, a large amount of water sources, etc., and achieves the effects of eliminating the hydrolysis of phthalic anhydride, having significant economic benefits and low reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

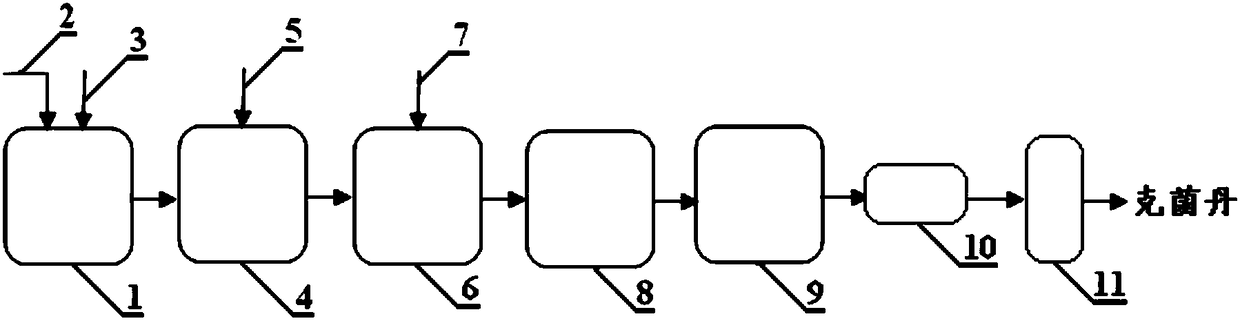

[0071] (1) According to phthalic anhydride, NH 3 , NaOH, trichlorothiochloromethane in a mol ratio of 1: 1.05: 1: 0.98 to get each raw material; drop into 15Kg phthalic anhydride (99.5%) and 7.2Kg ammoniacal liquor (content 25%) in the primary reactor, at 10m / s Carry out strong mixing under the stirring line speed of 10m / s, enter secondary reactor after staying 5min; Add 12.61Kg sodium hydroxide solution (content 32%) in secondary reactor again, carry out strong mixing under the stirring line speed of 10m / s After staying for 5 minutes, enter the third-stage reactor; then add 18.57Kg trichlorothiochloromethane (99%) to the third-stage reactor, and react at -5°C to 0°C under high-shear stirring at 2900r / min 15min (sequentially through the third-stage reactor for 5min, the fourth-stage reactor for 5min and the fifth-stage reactor for 5min), the reaction product was obtained;

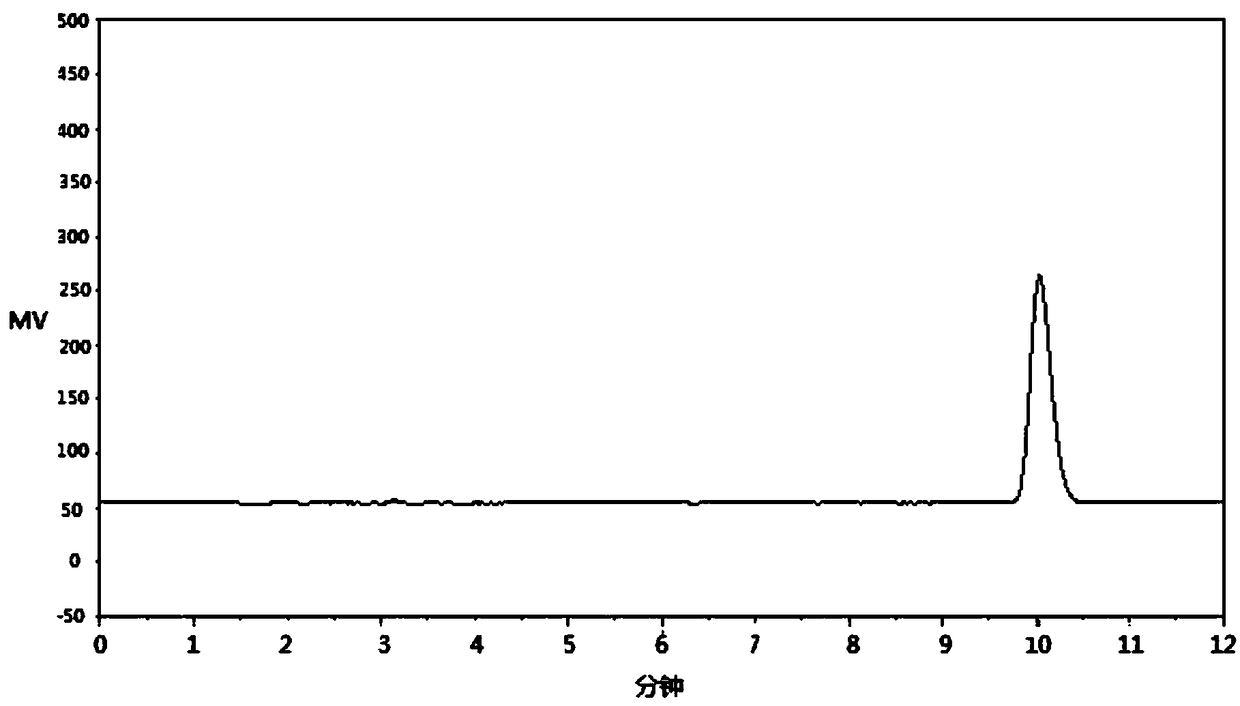

[0072](2) After the reaction product obtained in step (1) was filtered, it was dried at 105° C. to 115°...

Embodiment 2

[0077] (1) According to phthalic anhydride, NH 3 , NaOH, trichlorothiochloromethane in a molar ratio of 1:1:1.05:0.98 to get each raw material; drop 15Kg phthalic anhydride (99.5%) and 6.86Kg ammonia water (content 25%) into the primary reactor, and enter after staying for 2min Secondary reactor; Add 13.24Kg sodium hydroxide solution (content 32%) in secondary reactor again, enter tertiary reactor after staying 10min; Add 18.00Kg trichlorothiochloromethane ( 99%), under high-shear stirring at 2800r / min, react at -5°C to 0°C for 19min (stop in the third-stage reactor for 15min, the fourth-stage reactor for 2min and the fifth-stage reactor for 2min), get the reaction product;

[0078] (2) After the reaction product obtained in step (1) was filtered, it was dried at 105° C. to 115° C. for 20 minutes to obtain 29.53 Kg of the original captan.

[0079] As detected by HPLC, the content of captan was 97.50%, and the yield was 95.01%; very little trichlorothiochloromethane was detec...

Embodiment 3

[0081] (1) According to phthalic anhydride, NH 3 The mol ratio of NaOH, trichlorothiochloromethane is 1: 1.1: 1.1: 0.97 to get each raw material; Drop into 15Kg phthalic anhydride (99.5%) and 7.54Kg ammoniacal liquor (content 25%) in the primary reactor, enter after staying 6min Secondary reactor; Add 13.87Kg sodium hydroxide solution (content 32%) in secondary reactor again, enter tertiary reactor after staying 10min; Add 18.38Kg trichlorothiochloromethane ( 99%), under high-shear stirring at 3000r / min, react at -5°C to 0°C for 32min (in turn, stay in the third-stage reactor for 8min, the fourth-stage reactor for 15min and the fifth-stage reactor for 9min), get the reaction product;

[0082] (2) After the reaction product obtained in step (1) was filtered, it was dried at 105° C. to 115° C. for 20 minutes to obtain 29.53 Kg of the original captan.

[0083] As detected by HPLC, the content of captan was 97.56%, and the yield was 95.08%; very little trichlorothiochloromethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com