Preparation method for modified hydrophobic dispersion type white carbon black

A silica, dispersing technology, applied in chemical instruments and methods, dyeing low-molecular-weight organic compounds, fibrous fillers, etc. Improved compatibility and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

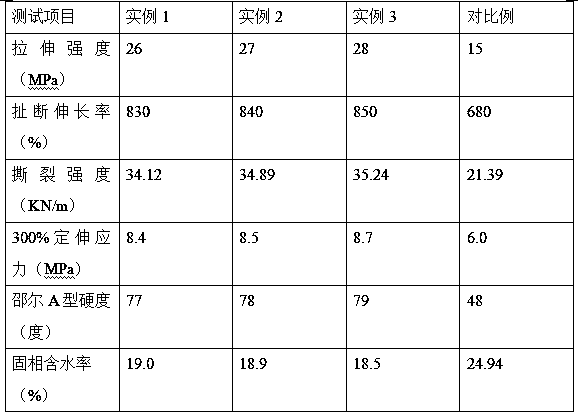

Examples

Embodiment Construction

[0021] Weigh 0.2-0.4 kg of rice husk and grind for 10-12 minutes to obtain rice husk powder, and add river bottom mud with a mass of 0.7% of rice husk powder to the rice husk powder, put it into a fermenter, and heat it at a temperature of 35-45°C Sealed fermentation for 3 to 5 days. After the fermentation, filter and remove the filtrate to obtain the fermentation filter residue, then put the fermentation filter residue into a carbonization furnace, carbonize at a temperature of 450 to 500°C for 1 to 2 hours, cool and discharge, and obtain carbonized rice husk ; Mix the carbonized rice husk and the sodium carbonate solution with a concentration of 0.5mol / L according to the mass-to-liquid ratio of 1:40 and pour it into a four-necked flask equipped with a thermometer, a stirrer and a condenser tube, and place it in a water bath. After bathing in water at a temperature of 95-100°C for 2-3 hours, remove the filter residue by filtration to obtain the filtrate, naturally cool to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com