Design and preparation method of nano mercury-removal material taking mussel shell as raw material

A mussel shell, mercury removal technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as ecological environment pollution and environmental pollution, and achieve the effect of promoting comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

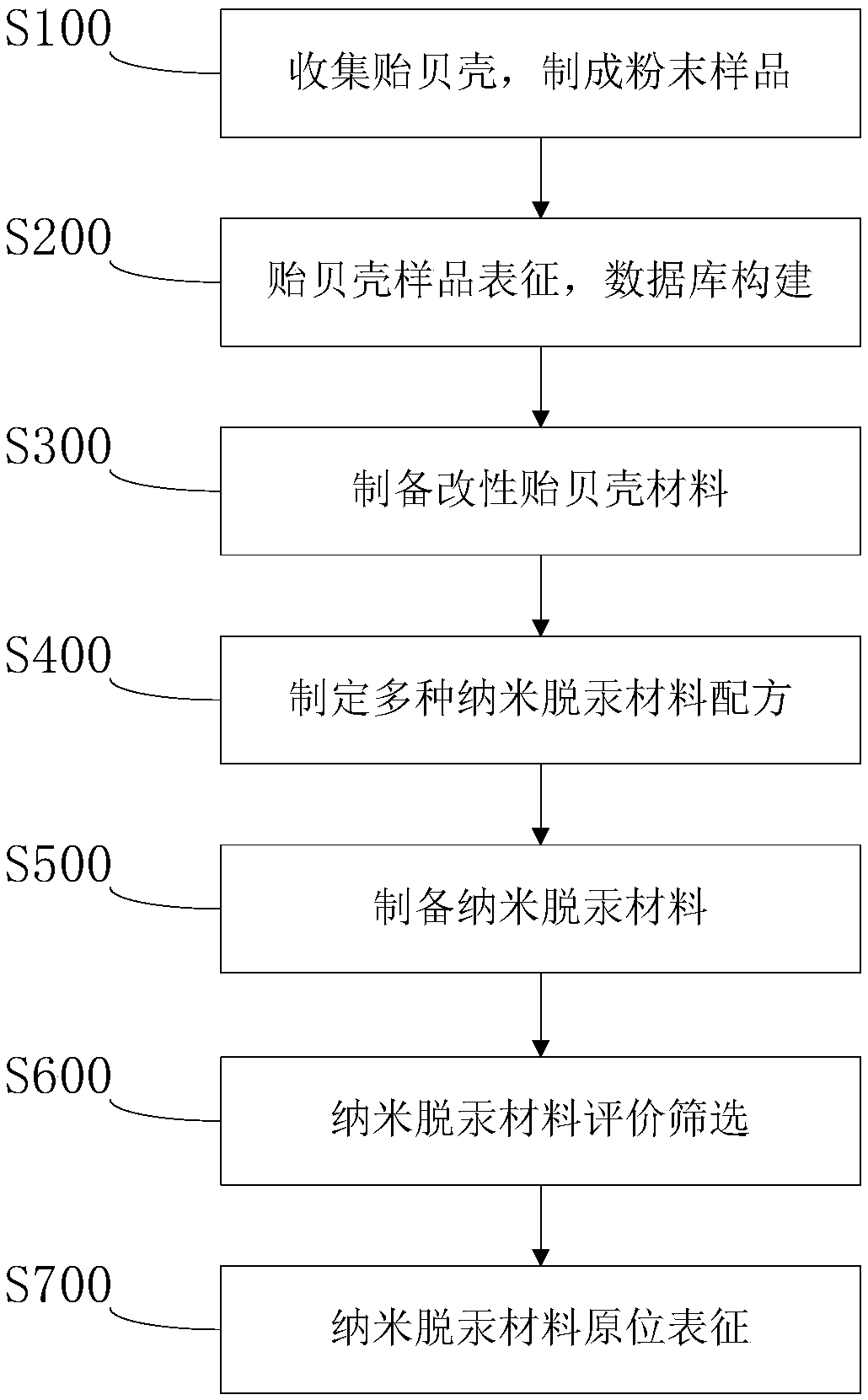

[0029] Mussel shell is a natural microporous mineralized material, its main chemical components include Ca and trace chemical components Cu, Zn, Fe, Co, Ni, Mn, Mg, etc., which have potential mercury removal performance. The present invention provides a design and preparation method of a nano mercury removal material using mussel shells as raw materials, such as figure 1 As shown, including the following steps:

[0030] S100: Collect typical mussel shells, wash the mussel shells with clean water, soak them in dilute hydrochloric acid for 1 hour, remove surface impurities, smash them in a high-speed grinder, and sieve through 60-100 meshes to obtain powdered mussel shell samples.

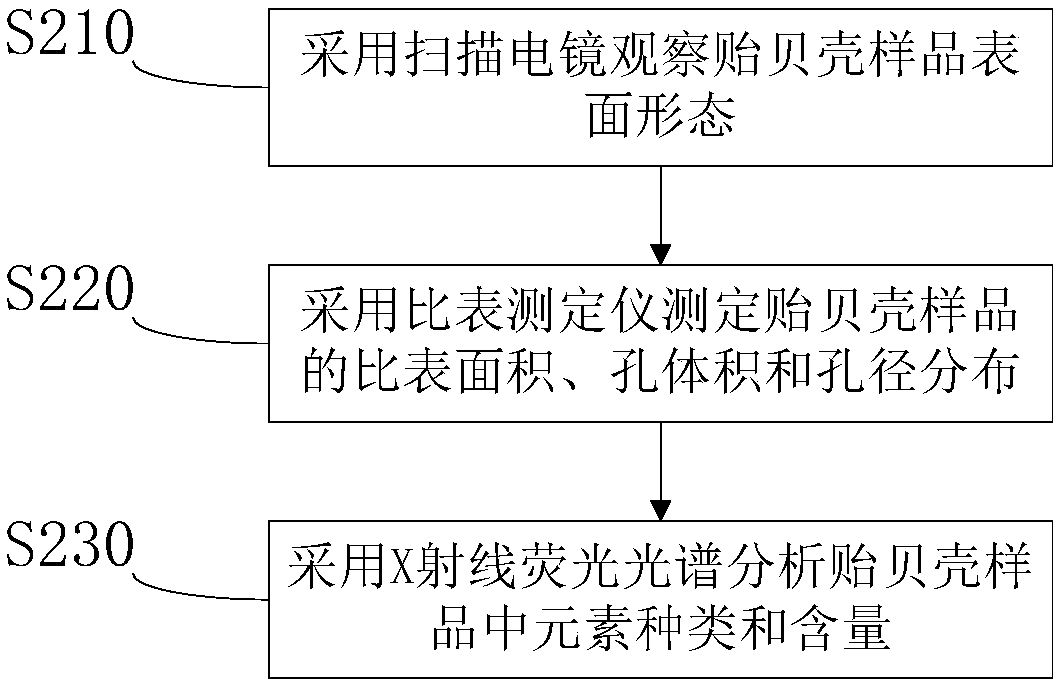

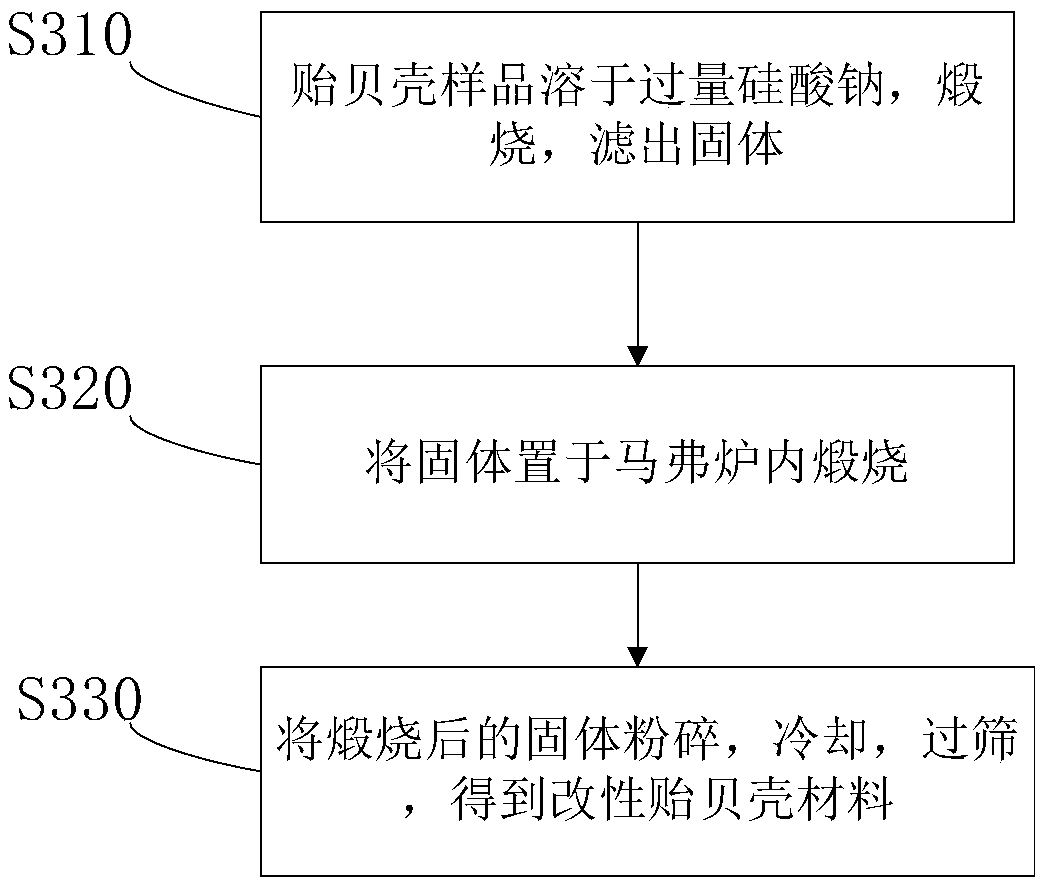

[0031] S200: Perform characterization analysis on a variety of mussel shell samples, record analysis data of various mussel shell samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com