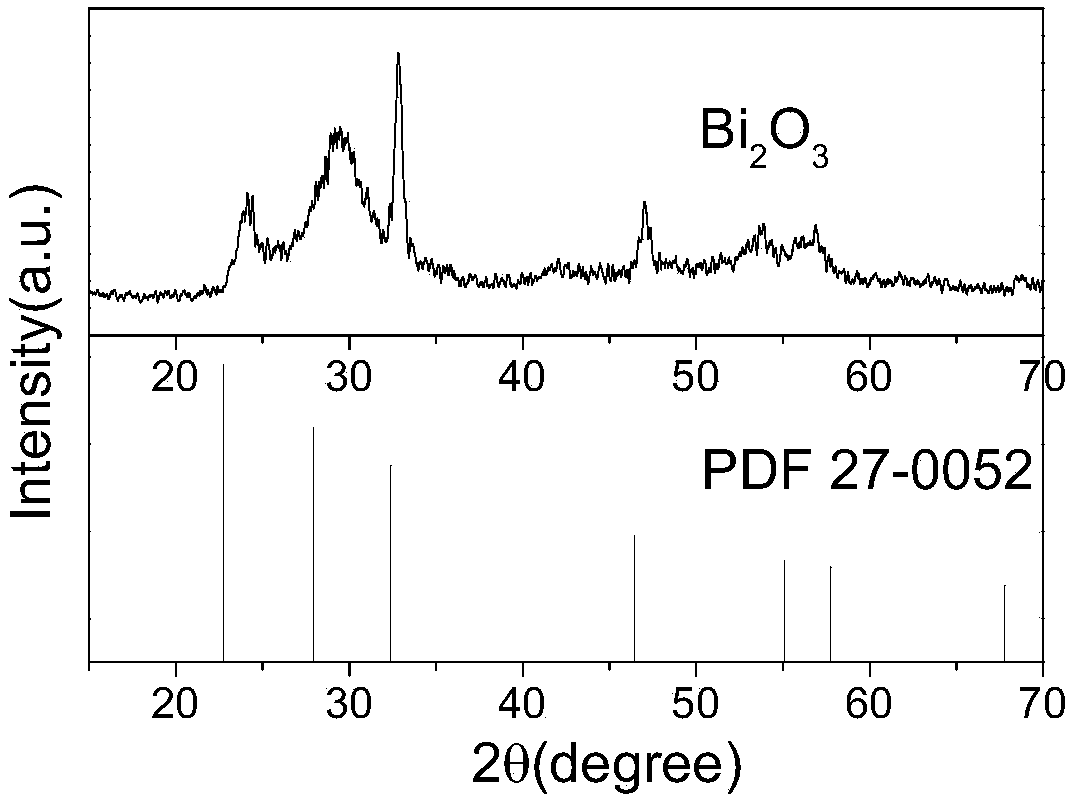

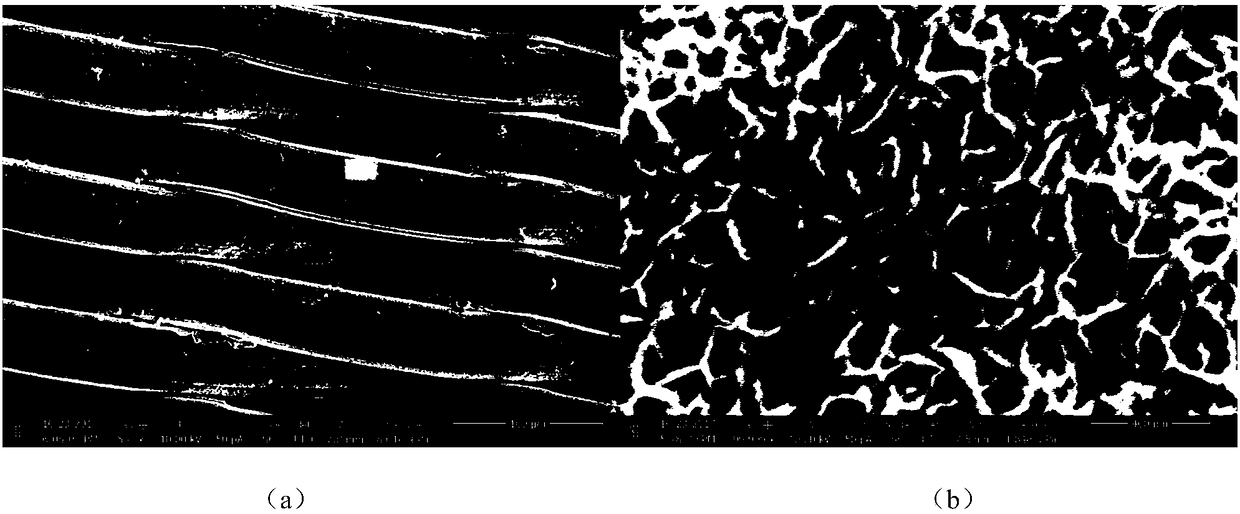

Method for preparing stainless steel wire loaded with bismuth oxide nanosheet photocatalyst through solvothermal method

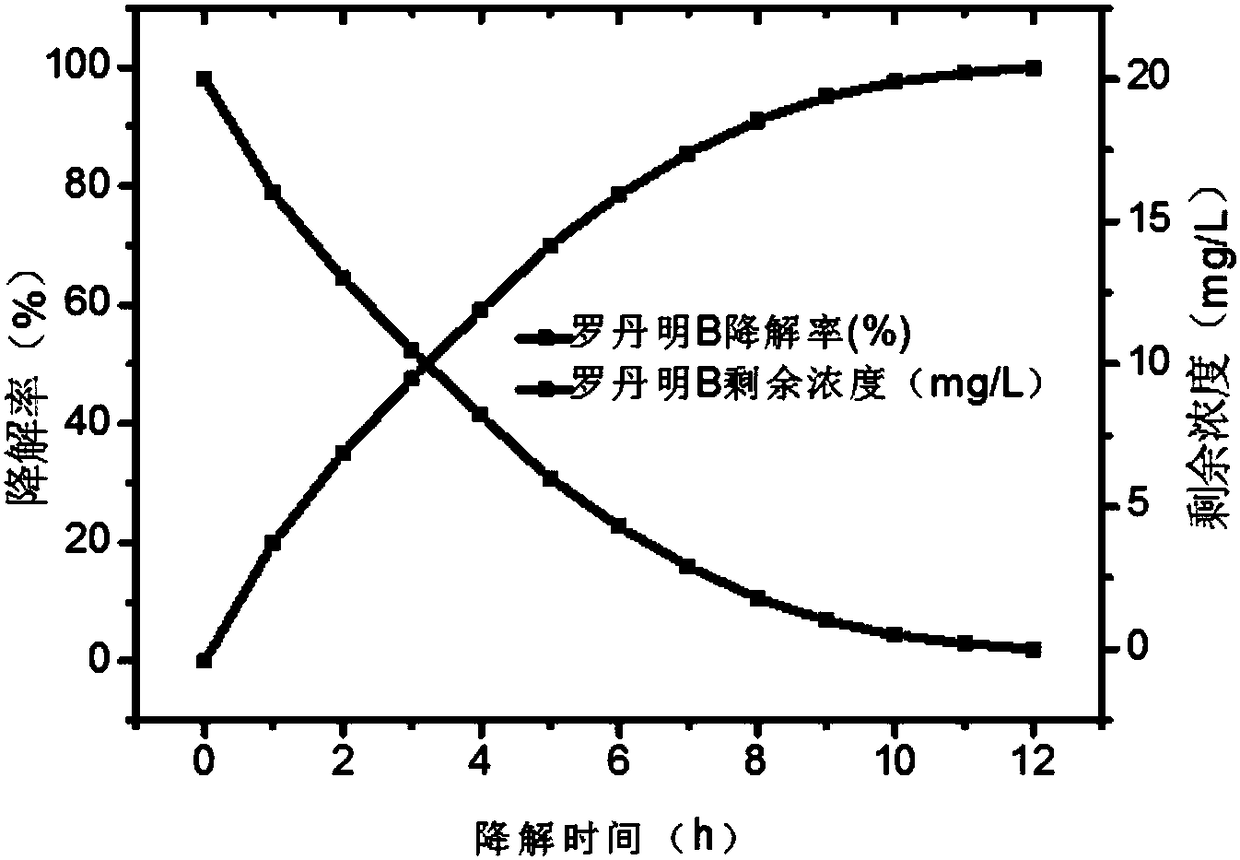

A stainless steel mesh, solvothermal technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low photocatalytic efficiency of thin film photocatalysts, nanometer Photocatalyst separation and recovery difficulties, etc., to achieve the effects of excellent product performance, optimized preparation process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A solvothermal method for preparation of Bi loaded on stainless steel mesh 2 o 3 The method for nanosheet photocatalyst, comprises the following steps:

[0042] 1) Ethylene glycol and acetone are mixed uniformly at a mass ratio of 3:1 to obtain solution A;

[0043] 2) Add bismuth nitrate to solution A, the amount of bismuth nitrate added is 1 / 24 of the amount of ethylene glycol added, stirring promotes the dissolution of bismuth nitrate, and completely dissolves to obtain solution B;

[0044] 3) Solution B is transferred to the reaction kettle, the filling degree of the hydrothermal reaction kettle is 70%, the stainless steel mesh is cleaned with deionized water and ethanol and completely immersed in the solution B, the hydrothermal reaction temperature is 150°C, and the hydrothermal reaction time is After 12 hours, the hydrothermal reaction needs to be naturally cooled to room temperature.

[0045] 4) After the reaction, take out the stainless steel mesh, ultrasonic...

Embodiment 2

[0047] A solvothermal method for preparation of Bi loaded on stainless steel mesh 2 o 3 The method for nanosheet photocatalyst, comprises the following steps:

[0048] 1) Ethylene glycol and acetone are mixed uniformly at a mass ratio of 2:1 to obtain solution A;

[0049] 2) Take bismuth nitrate and add it to solution A, the amount of bismuth nitrate added is 1 / 20 of the amount of ethylene glycol added, ultrasonically promotes the dissolution of bismuth nitrate, and completely dissolves to obtain solution B;

[0050] 3) Solution B is transferred to the reaction kettle, the filling degree of the hydrothermal reaction kettle is 75%, the stainless steel mesh is cleaned with deionized water and ethanol and completely immersed in the solution B, the hydrothermal reaction temperature is 155 °C, and the hydrothermal reaction time is After 11.5h, the hydrothermal reaction needs to be naturally cooled to room temperature.

[0051] 4) After the reaction, the stainless steel mesh was ...

Embodiment 3

[0053] A solvothermal method for preparation of Bi loaded on stainless steel mesh 2 o 3 The method for nanosheet photocatalyst, comprises the following steps:

[0054] 1) Ethylene glycol and acetone are mixed uniformly at a mass ratio of 2.5:1 to obtain solution A;

[0055] 2) Add bismuth nitrate to solution A, the amount of bismuth nitrate added is 1 / 18 of the amount of ethylene glycol added, stirring promotes the dissolution of bismuth nitrate, and completely dissolves to obtain solution B;

[0056] 3) Solution B is transferred to the reaction kettle, the filling degree of the hydrothermal reaction kettle is 80%, the stainless steel mesh is cleaned with deionized water and ethanol and completely immersed in solution B, the hydrothermal reaction temperature is 160 °C, and the hydrothermal reaction time is After the completion of the hydrothermal reaction, it needs to be naturally cooled to room temperature.

[0057] 4) After the reaction, the stainless steel mesh was taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com