Recovery and treatment method for alkali residues produced in soda ash production

A technology for recycling and processing alkali residues, applied in chemical instruments and methods, preparation/separation of ammonia, removal of solid waste, etc. It can solve the problems of high processing cost, poor quality and low added value of products, and reduce steam consumption , the effect of reducing the production load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

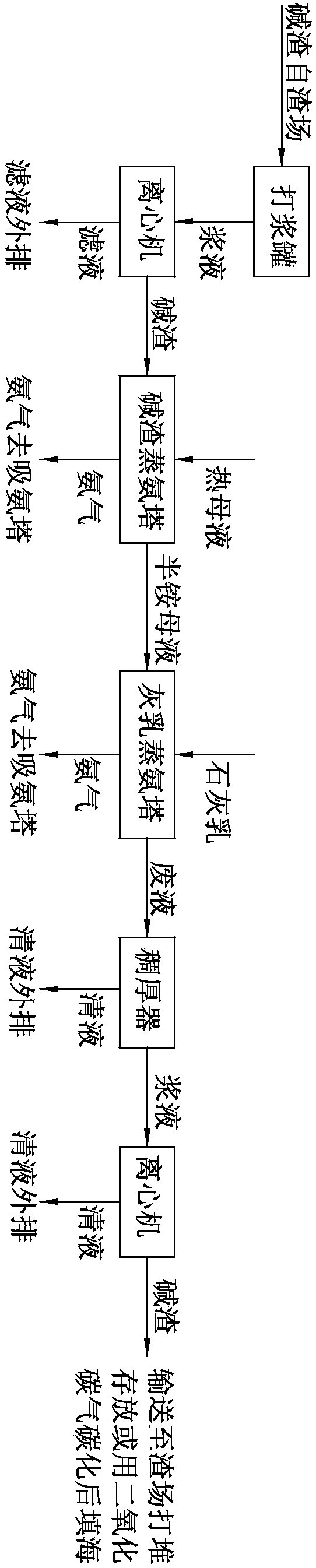

Method used

Image

Examples

Embodiment 1

[0037] The alkali slag is centrifugally separated and dehydrated by a centrifuge until the water content is 45wt%, and the ammonia distillation reaction is carried out with the hot mother liquor at a temperature of 79°C in the ammonia distillation tower. The ammonium chloride content in the hot mother liquor is 3.0mol / l, and each mother liquor Add alkali slag to a dry basis of 0.10t, control the pH value of the liquid in the ammonia distillation tower to 8.5, and keep the excess ammonium chloride in the mother liquor; the bottom pressure of the ammonia distillation tower is 12kPa; the outlet pressure is -12kPa; the tower bottom temperature It is 100°C; the outlet gas temperature at the top of the tower is 78°C; the first mother liquor ammonia distillation time is 8 minutes; the ammonium chloride content in the semi-ammonium mother liquor after the mother liquor ammonia distillation is completed is 1.0mol / l.

[0038] The half-ammonium mother liquor after the mother liquor has be...

Embodiment 2

[0041] The alkali slag is dehydrated by centrifugal separation and dehydration until the water content is 50wt%, and the ammonia distillation reaction is carried out with the hot mother liquor at a temperature of 80°C in the ammonia distillation tower. The ammonium chloride content in the hot mother liquor is 3.2mol / l, and each mother liquor Add alkali slag to a dry basis of 0.11t, control the pH value of the liquid in the ammonia distillation tower to 8.5, and keep the excess ammonium chloride in the mother liquor; the bottom pressure of the ammonia distillation tower is 15kPa; the gas outlet pressure is -12.5kPa; The temperature is 102°C; the outlet gas temperature at the top of the tower is 80°C; the first mother liquor ammonia distillation time is 6 minutes; the ammonium chloride content in the semi-ammonium mother liquor after the mother liquor ammonia distillation is completed is 1.2mol / l.

[0042] Transfer the ammonium semi-ammonium mother liquor after ammonia distillati...

Embodiment 3

[0045] The alkali slag is centrifugally separated and dehydrated by a centrifuge until the water content is 55wt%, and the ammonia distillation reaction is carried out with the hot mother liquor at a temperature of 82°C in the ammonia distillation tower. The ammonium chloride content in the hot mother liquor is 3.5mol / l, and each mother liquor Add alkali slag to a dry basis of 0.12t, control the pH value of the liquid in the ammonia distillation tower to 9.0, and keep the excess ammonium chloride in the mother liquor; the bottom pressure of the ammonia distillation tower is 16kPa; the outlet pressure is -13kPa; the tower bottom temperature It is 104 DEG C; the tower top outlet gas temperature is 82 DEG C; the first mother liquor ammonia distillation time is 5 minutes; the ammonium chloride content in the semi-ammonium mother liquor after the mother liquor ammonia distillation is finished is 1.45mol / l.

[0046] Transfer the ammonium semi-ammonium mother liquor after ammonia dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com