A kind of residual oil catalyst and its preparation method and application

A catalyst and residual oil technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of increasing reactor load, reducing catalyst activity, and product separation. Difficulties and other problems, to achieve the effect of reducing solid content, reducing wear, and high cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

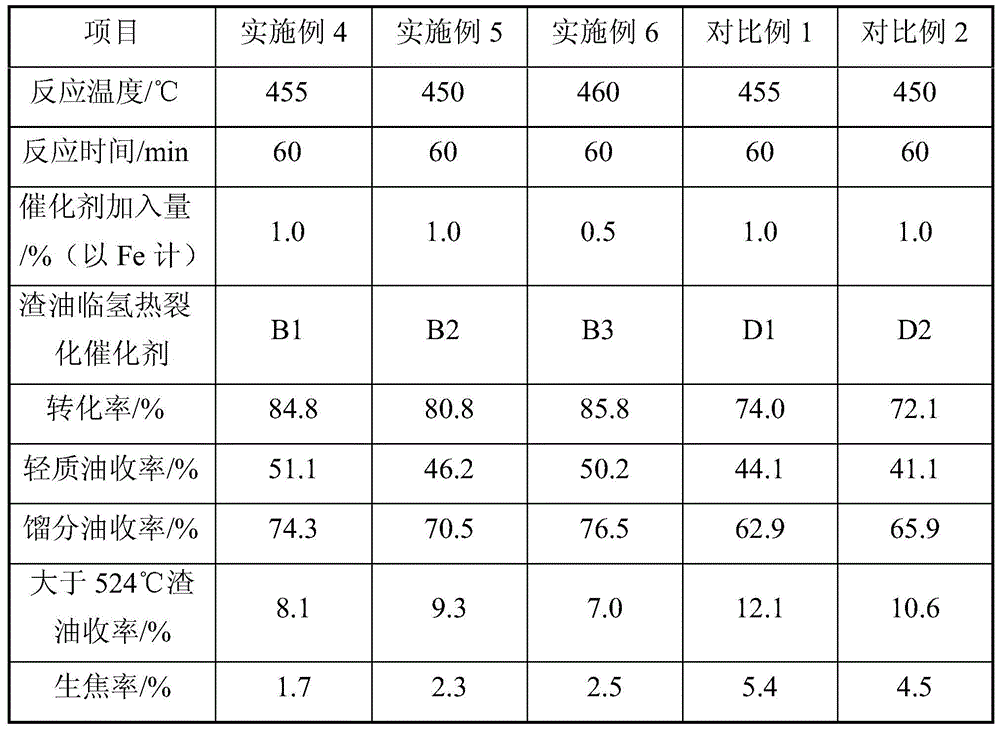

Embodiment 1

[0039]Dissolve 58.0g of ferrous sulfate heptahydrate and 0.20g of EDTA in 400g of deionized water, add 200.0g of C1 and stir evenly, take another 25.0g of ammonia water and drop into the above solution while stirring, and continue to stir for 40min, then perform suction filtration and washing to obtain The filter cake was dried at 110°C for 2 hours to obtain solid particles. Another 20 mL of acetic acid solution with a pH value of 2.8 was sprayed onto the above powder and stirred for 20 min, then dried at 110°C for 3 hours, and the residual oil catalyst obtained by grinding was denoted as B1, and the iron content in B1 was analyzed to be 5.1% by weight , the water content is 2.0% by weight.

Embodiment 2

[0041] Weigh 58g of ferrous sulfate heptahydrate and put it into a beaker, add 200g of deionized water and stir continuously to dissolve, add 150.0g of C2 and stir to mix evenly, add 25g of ammonia water drop by drop while stirring, continue to stir for 60min, then suction filter, After washing, the obtained filter cake was dried at 105° C. for 2 hours to obtain solid particles. Another 30 mL of sulfuric acid solution with a pH value of 1.45 was sprayed onto the above powder and stirred for 20 min, then dried at 110°C for 3 hours, and the residual oil catalyst obtained by grinding was denoted as B2, and the iron content in B2 was analyzed to be 6.5% by weight , the water content is 1.8% by weight.

Embodiment 3

[0043] Weigh 80g of ferric chloride and 0.55g of diammonium hydrogen phosphate into a beaker, add 100g of deionized water and stir to dissolve continuously, weigh 80.0g of C3 and stir to mix evenly, add 30g of ammonia water drop by drop while stirring. Inject air and continue to stir for 60 minutes, then suction filter and wash to obtain a filter cake and dry it at 105°C for 5 hours to obtain solid particles. Another 15 mL of sulfuric acid solution with a pH value of 1.9 was sprayed onto the above powder and stirred for 30 min, then dried at 110°C for 3 hours, and the residual oil catalyst obtained by grinding was designated as B3. The iron content in the B3 catalyst was 20.0% by weight, and the water content was 1.5% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com