Multi-effect restoration material for restoration of black and odorous water body, preparation method and application thereof

A technology for repairing materials and black and odorous water bodies, which is applied in chemical instruments and methods, water/sewage treatment, biological water/sewage treatment, etc. , Improve the effect of pH increase and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

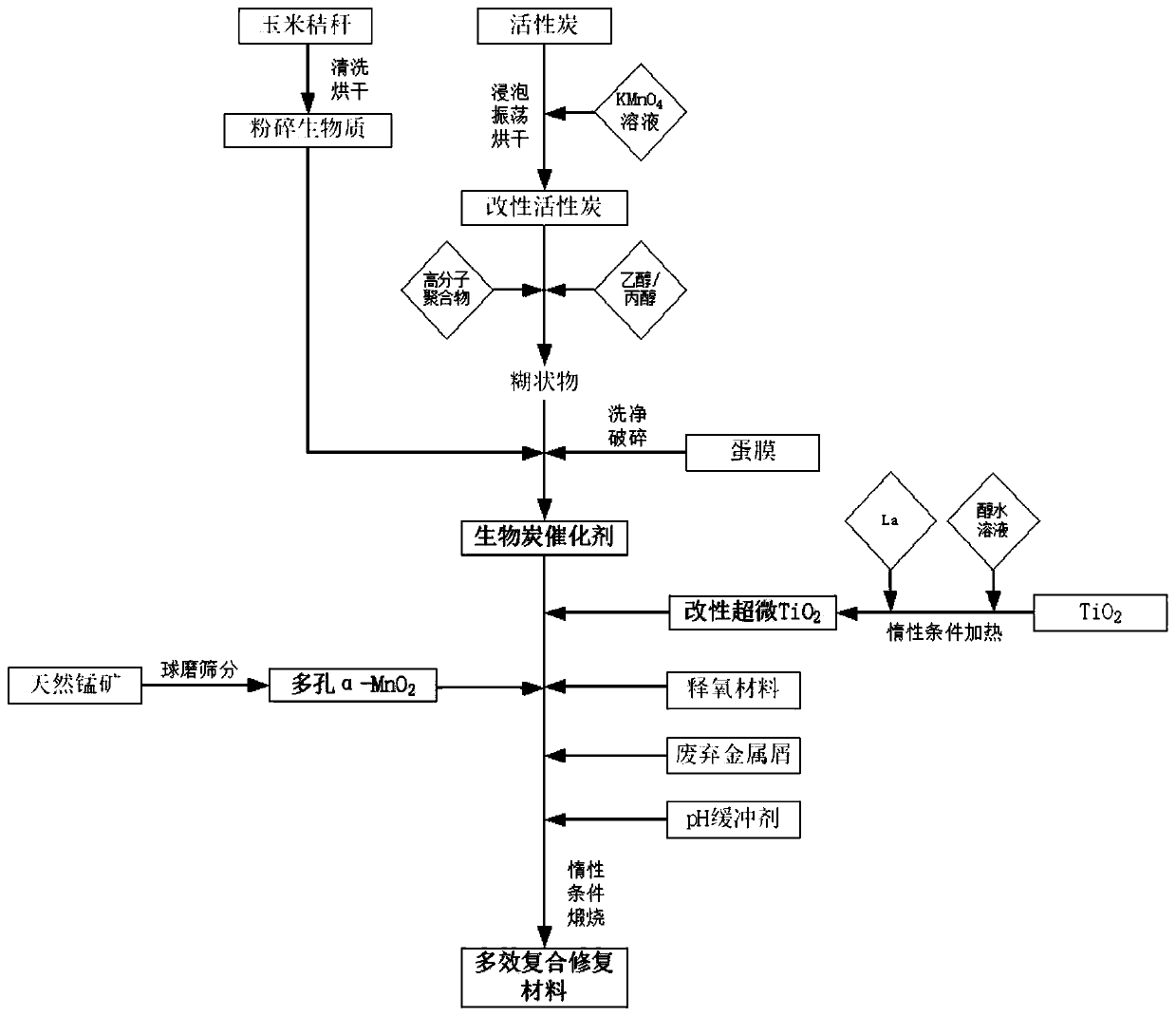

Image

Examples

preparation example Construction

[0051] The preparation method of the multi-effect restorative material of the present invention comprises the following steps:

[0052] A. Natural porous α-MnO 2 Put it into the planetary ball mill for 8-15 hours, and then sieve to obtain the natural porous α-MnO with a particle size of 50-120 mesh, a pore structure, and a pore size of 0.21-52.43nm. 2 type material particles;

[0053] B. Preparation of biochar catalyst:

[0054] ① Wash the collected biomass repeatedly for 3-5 times, rinse it with water, put it in an oven at 50°C for 8-18 hours, and crush and seal the dried biomass for later use;

[0055] ②Immerse 1000g of activated carbon in 0.1-0.3mol / L potassium permanganate solution, shake continuously at the speed r=100r / min in a constant temperature water bath oscillator at 20°C for 18-24h, let it stand for 20-48h, take out the activated carbon and rinse repeatedly , dried at 60°C to obtain modified activated carbon for use;

[0056] ③Collect the egg membrane, wash it...

Embodiment 1

[0065] In parts by mass, 26 parts of oxygen-releasing material, natural porous α-MnO 2 23 parts of type material particles, 8 parts of additives, 17 parts of biochar catalyst, 8 parts of modified ultrafine titanium dioxide, 12 parts of waste metal shavings and 6 parts of pH buffering agent were used to prepare composite restoration materials. The composite restorative material prepared above was placed in 300mg / L phenol solution, and the dosage was 8g / L. After reacting for 24 hours, measure the phenol concentration and TOC in the solution. The results showed that after 24 hours, the removal efficiency of phenol reached 97.8%, and the removal rate of TOC reached 93.4%.

Embodiment 2

[0067] In parts by mass, 25 parts of oxygen-releasing material, natural porous α-MnO 2 25 parts of type material particles, 7 parts of additives, 19 parts of biochar catalyst, 9 parts of modified ultrafine titanium dioxide, 8 parts of waste metal shavings and 5 parts of pH buffer were used to prepare composite restoration materials. The composite restorative material prepared above was placed in 300mg / L phenol solution, and the dosage was 8g / L. After reacting for 24 hours, measure the phenol concentration and TOC in the solution. The results showed that after 24 hours, the removal efficiency of phenol reached 99.8%, and the removal rate of TOC reached 96.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com