Coarse slag damp-heat curing brick and production method thereof

A technology of damp heat curing and production technology, which is applied in the field of building materials, can solve problems such as environmental damage, pollution, and reduce the weight of walls, and achieve the effects of improving thermal insulation performance, increasing the use area, and reducing apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

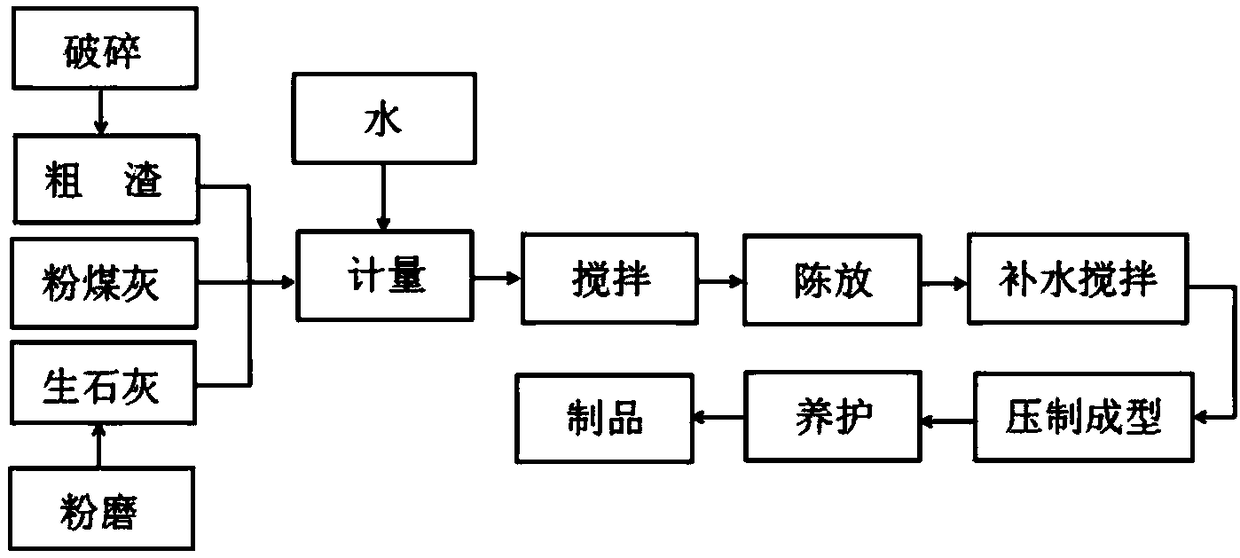

[0057] (1) Raw material preparation: crush the coarse slag greater than 10mm particle size to a particle size of 5-10mm, and grind quicklime for use;

[0058] (2) Measurement: by weight, take 150kg of coarse slag, 750kg of fly ash, and 100kg of quicklime;

[0059] (3) Stirring: add water to the measured raw materials and stir, the amount of water added is 9% of the total weight of the material, and the stirring speed is 30r / min;

[0060] (4) aging: according to the digestion speed of quicklime, aging until the digestion is completed;

[0061] (5) Moisturizing and stirring: after aging, measure the remaining moisture content of the material, add water to 9% moisture content, and stir;

[0062] (6) Compression molding: 24MPa pressure for compression molding;

[0063] (7) Curing: heat up for 2 hours, keep the temperature at 180°C for 7 hours, and cool down for 2.5 hours.

[0064] Finished product inspection: density

Embodiment 2

[0066] (1) Raw material preparation: crush the coarse slag greater than 10mm particle size to a particle size of 5-10mm, and grind quicklime for use;

[0067] (2) Measurement: by weight, take 300kg of coarse slag, 600kg of fly ash, and 100kg of quicklime;

[0068] (3) Stirring: add water to the measured raw materials and stir, the amount of water added is 6% of the total weight of the material, and the stirring speed is 30r / min;

[0069] (4) aging: according to the digestion speed of quicklime, aging until the digestion is completed;

[0070] (5) Moisturizing and stirring: after aging, measure the remaining moisture content of the material, add water to 6% moisture content, and stir;

[0071] (6) Compression molding: 16MPa pressure for compression molding;

[0072] (7) Curing: heat up for 2.5 hours, keep the temperature at 80°C for 20 hours, and cool down for 2 hours.

Embodiment 3

[0074] (1) Raw material preparation: crush the coarse slag greater than 10mm particle size to a particle size of 5-10mm, and grind quicklime for use;

[0075] (2) Measurement: by weight, take 200kg of coarse slag, 650kg of pulverized coal, and 150kg of quicklime;

[0076] (3) Stirring: add water to the measured raw materials and stir, the amount of water added is 8% of the total weight of the material, and the stirring speed is 30r / min;

[0077] (4) aging: according to the digestion speed of quicklime, aging until the digestion is completed;

[0078] (5) Moisturizing and stirring: after aging, measure the remaining moisture content of the material, add water to 8% moisture content, and stir;

[0079] (6) Compression molding: 20MPa pressure for compression molding;

[0080] (7) Curing: heat up for 2 hours, keep the temperature at 190°C for 7 hours, and cool down for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com